Preparation method of magnetic microcapsules coated with metal complex

A metal complex and microcapsule technology is applied in the field of metal complex microcapsule preparation to achieve the effects of firm structure, good adsorption and permeability performance, and few influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

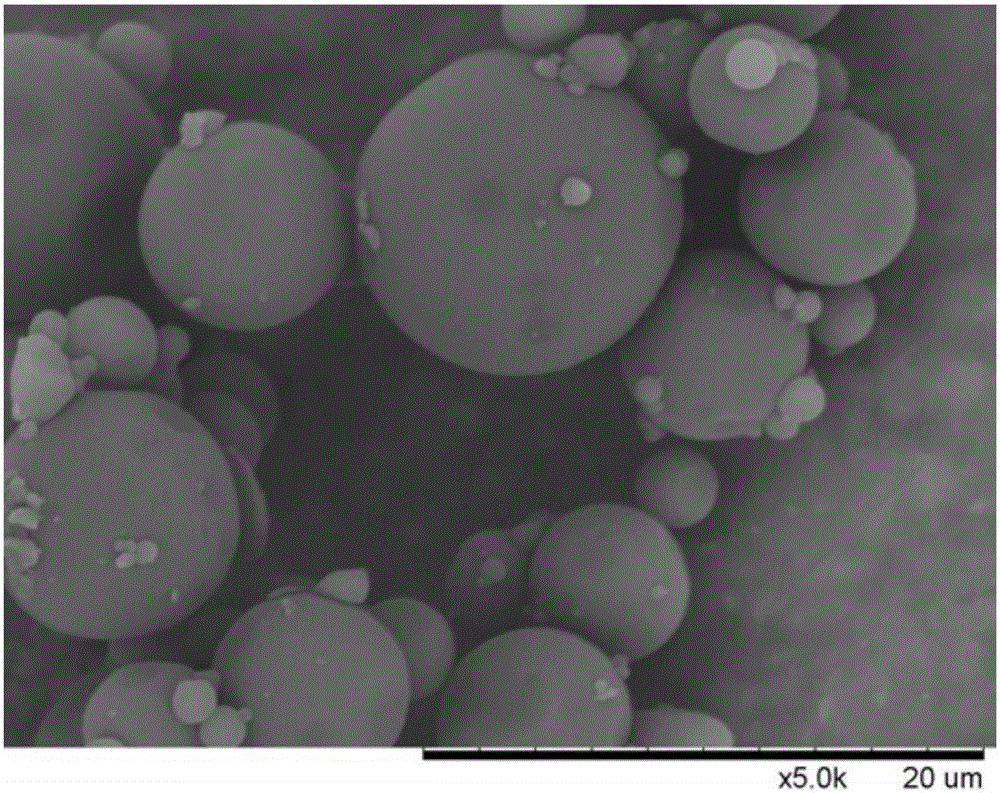

[0037] Pre-configured 0.1% homogeneous catalyst complex CoC 18 h 16 N 2 o 4 0.5(H 2 O) 50mL aqueous solution, add 10g gelatin, mechanically stir at 20°C, and add 1g magnetic γ-Fe 2 o 3 Powder, high-speed homogeneous (stirring speed is 10000rpm, time is 15min) after dispersion, adding 210g mass ratio of liquid paraffin-Span80 oil phase dispersed phase (the speed of stirring during preparation is 400rpm; the temperature of water bath heating is 60°C for 25min), stirred at 10000rpm for 15min, cooled to 3°C in an ice bath, added hydrochloric acid to adjust the pH to 3, and then added 5mL of 25% glutaraldehyde aqueous solution (the dropping rate was 1 drop / second) for cross-linking. Stir at 450rpm for 180min, then add isopropanol for dehydration, filter with suction and wash the filter cake with petroleum ether to obtain magnetic microcapsules coated with metal complexes with excellent dispersibility, such as figure 1 shown.

Embodiment 2

[0039] Pre-configured 0.1% homogeneous catalyst complex CoC 18 h 16 N 2 o 4 0.5(H 2 O) 50 mL of aqueous solution, add 5 g of gelatin, mechanically stir at 20 ° C, and add 2 g of magnetic nano-iron powder, high-speed homogenization (stirring speed is 10000 rpm, time is 15 min) after dispersion, add 210 g of liquid paraffin with a mass ratio of 40:1 -Span80 oil phase dispersed phase (stirring speed during preparation is 400rpm; heating temperature in water bath is 60°C, time is 25min), cool down to 3°C in ice bath, add hydrochloric acid to adjust pH to 3, then add 25% glutaraldehyde Aqueous solution 7mL (drop rate: 1 drop / second) was cross-linked, stirred at 400rpm for 150min, then added isopropanol for dehydration, suction filtered and petroleum ether was used to wash the filter cake, and a coated metal complex with excellent dispersibility was obtained. magnetic microcapsules.

Embodiment 3

[0041] Pre-configured 0.1% homogeneous catalyst complex CoC 18 h 16 N 2 o 4 0.5(H 2 O) 50 mL of aqueous solution, add 5 g of gelatin, mechanically stir at 20 ° C, and add 3 g of magnetic Fe 3 o 4 Powder, high-speed homogeneous (stirring speed is 10000rpm, time is 15min) after dispersion, add 210g mass ratio and be the liquid paraffin-Span80 oil phase dispersed phase of 30:1 (the speed of stirring during preparation is 400rpm; The temperature of water bath heating is 60°C for 25min), cool down to 3°C in an ice bath, add hydrochloric acid to adjust the pH to 3, then add 8mL of 25% glutaraldehyde aqueous solution (drop rate: 1 drop / second) for crosslinking, and stir at 200rpm for 150min , and then add isopropanol for dehydration, filter with suction and wash the filter cake with petroleum ether to obtain magnetic microcapsules coated with metal complexes with excellent dispersibility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com