Preparation method for electroporation electrode structure and application

An electrode structure and electroporation technology, applied in chemical instruments and methods, coating of superimposed layers, special treatment targets, etc., can solve problems such as high cost and high voltage, prevent corrosion, reduce work difficulty, and enhance electric field strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

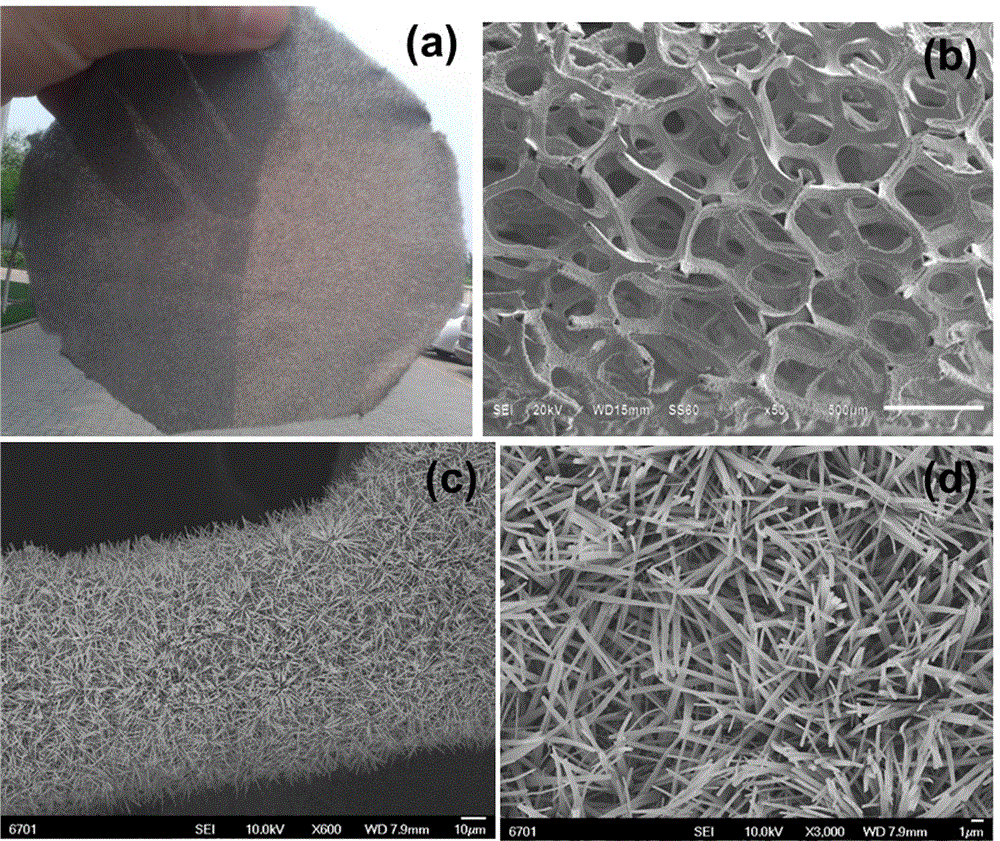

Embodiment 1

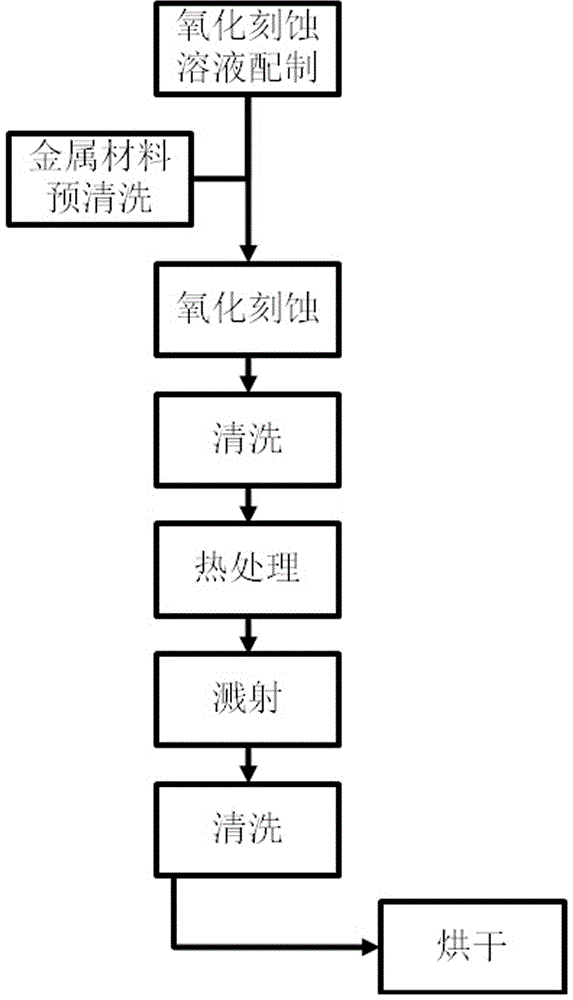

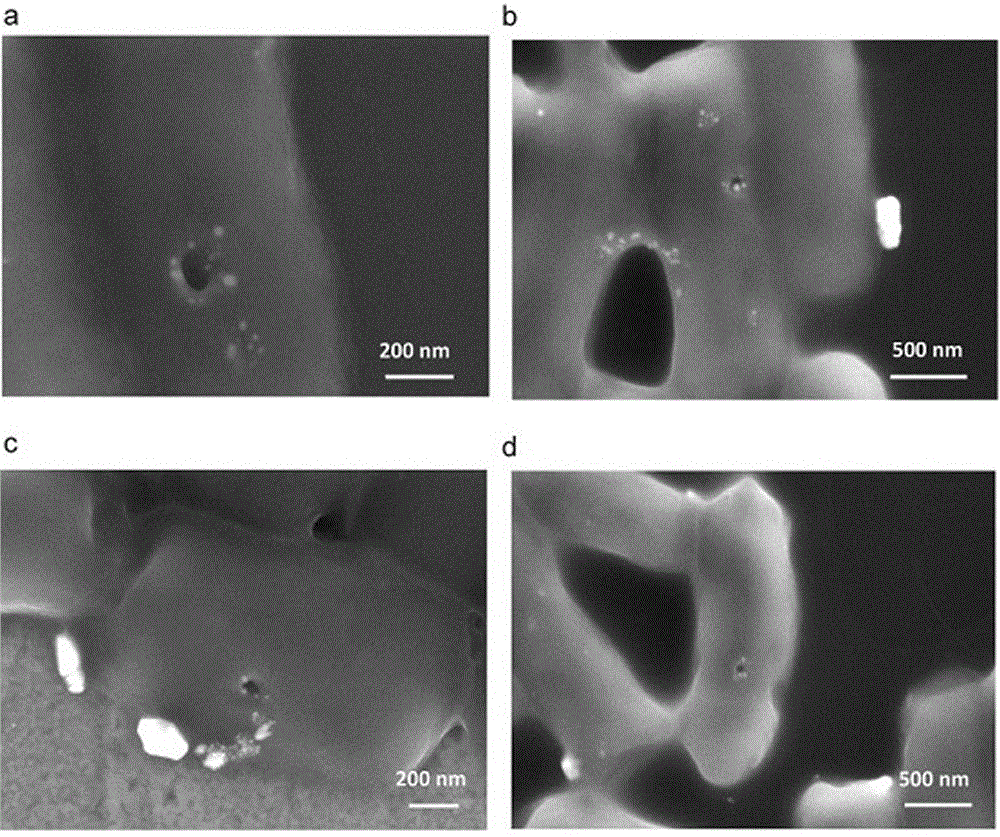

[0035] A preparation method of an electroporation electrode structure, the steps are: 1) successively adding sodium hydroxide and ammonium persulfate into deionized water to prepare an oxidizing solution, wherein the concentration of the sodium hydroxide aqueous solution is 2 mol / L, and the The molar concentration ratio of sodium and ammonium persulfate is 20:1, and it is cooled to room temperature for later use; the initial metal material copper foam is cleaned with organic solvents such as absolute ethanol or acetone and deionized water to remove surface oil and other impurities; The good foamed copper is completely immersed in the above oxidizing solution and oxidized for 30 minutes. 2) Take out the above oxidized copper material, rinse it with deionized water for 3-5 times, and then put it into a thermostat at 200°C for heat treatment for 3 hours. 3) The copper foam material after oxidation etching and heat treatment is placed on the sample base of the sputtering equipment...

Embodiment 2

[0037] A preparation method of an electroporation electrode structure, the steps are: 1) adding sodium hydroxide and ammonium persulfate successively to deionized water to prepare an oxidizing solution, wherein the concentration of the sodium hydroxide aqueous solution is 2.5mol / L, the hydrogen The molar concentration ratio of sodium oxide and ammonium persulfate is 30:1, and it is cooled to room temperature for use; the initial metal material aluminum is washed with organic solvents such as absolute ethanol or acetone and deionized water to remove surface oil and other impurities; The good aluminum was completely immersed in the above-mentioned oxidizing solution and oxidized for 20 minutes. 2) Take out the above oxidized aluminum material, rinse it with deionized water for 3-5 times, and then put it into a thermostat at 180°C for heat treatment for 5 hours. 3) The foamed aluminum material after oxidation etching and heat treatment is placed on the sample base of the sputteri...

Embodiment 3

[0039] A preparation method of an electroporation electrode structure, the steps are: 1) adding sodium hydroxide and ammonium persulfate successively to deionized water to prepare an oxidizing solution, wherein the concentration of the sodium hydroxide aqueous solution is 3 mol / L, and the The molar concentration ratio of sodium and ammonium persulfate is 25:1, and it is cooled to room temperature for use; the initial metal material copper foam is cleaned with organic solvents such as absolute ethanol or acetone and deionized water to remove surface oil and other impurities; The good foamed copper is completely immersed in the above oxidizing solution and oxidized for 10 minutes. 2) Take out the above oxidized copper material, rinse it with deionized water for 3-5 times, and then put it into a thermostat at 150°C for heat treatment for 6 hours. 3) The copper foam material after oxidation etching and heat treatment is placed on the sample base of the sputtering equipment, and na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com