A kind of blackening processing method of lithium tantalate crystal substrate

A treatment method, lithium tantalate technology, applied in chemical instruments and methods, after treatment, crystal growth, etc., can solve the problems of complex process of Shin-Etsu Company, difficult control of process conditions of Sumitomo Company, hidden safety hazards, etc., to improve discharge phenomenon, Ease of control and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

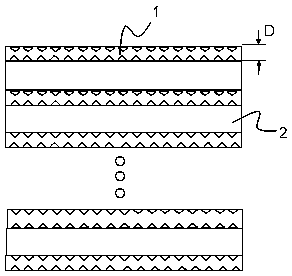

Embodiment 1

[0032] This embodiment provides a blackening treatment method for a lithium tantalate crystal substrate. The surface of the metal sheet 1 is roughened by wet etching, and hydrofluoric acid, nitric acid or a mixture of the two is used for roughening by wet etching. The wet etching temperature is 20-80° C., and the wet etching time of the metal sheet is 3-10 minutes. The surface roughness Ra of the metal sheet 1 after treatment is 0.1 ~ 10um, refer to figure 1 In the cavity, the roughened metal sheet 1 and the lithium tantalate crystal substrate 2 are alternately stacked in a contact manner, wherein the material of the metal sheet 1 can be Al, Ti, Zn or Fe, and the material of the metal sheet 1 is preferably Al , the thickness D of the metal sheet 1 is 0.05-20 mm, placed in an environment lower than the Curie temperature, and the lithium tantalate crystal substrate 2 is reduced. Specifically, the ambient temperature during blackening treatment is 350-600°C, and the treatment t...

Embodiment 2

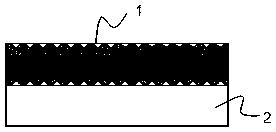

[0036] The difference between this embodiment and Embodiment 1 is that the surface of the lithium tantalate crystal substrate 2 is roughened, and the roughening is carried out by wet etching with hydrofluoric acid, nitric acid or a mixture of the two, and the wet etching temperature is Between 20 and 80 degrees Celsius, the wet etching time for the metal sheet is 3 to 10 minutes, and the wet etching time for the lithium tantalate crystal substrate is 3 to 10 hours. The surface roughness Ra of lithium tantalate crystal substrate 2 after treatment is 0.1~10um, see Figure 4 , stacking the roughened lithium tantalate crystal substrate 2 and the unroughened metal sheet 1 for reduction treatment.

[0037] Compared with the prior art, after the lithium tantalate crystal substrate is ground, a better flatness is obtained and then the reduction reaction is performed. The reduction reaction performance of the roughened lithium tantalate crystal substrate is better than that after grind...

Embodiment 3

[0040] According to the prior art, most of the current blackening processes are carried out after slicing. In combination with Embodiment 1 and Embodiment 2, this embodiment proposes a technical solution for roughening the metal sheet 1 and the lithium tantalate crystal substrate 2 respectively. Roughening is carried out by wet etching with hydrofluoric acid, nitric acid or a mixture of the two. The wet etching temperature is between 20~80°C. The wet etching time of the metal sheet is 3~10 minutes. Lithium tantalate The wet etching time of the crystal substrate is 3-10 hours. After roughening, the surface roughness Ra of the metal sheet 1 and the lithium tantalate crystal substrate 2 is 0.1-10 um.

[0041] see Figure 7 In the cavity, the roughened metal sheet 1 and lithium tantalate crystal substrate 2 are alternately stacked in a contact manner, wherein the material of the metal sheet 1 can be Al, Ti, Zn or Fe, and the thickness D of the metal sheet 1 is 0.05 ~20mm, place ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com