High strength 3D printing support material with fast water solubility and preparation method thereof

A support material, 3D printing technology, used in rayon manufacturing, textiles and papermaking, single-component synthetic polymer rayon, etc., can solve the problem of not being able to play a supporting role well, plasticizers that are not environmentally friendly, and support materials Toxicity etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

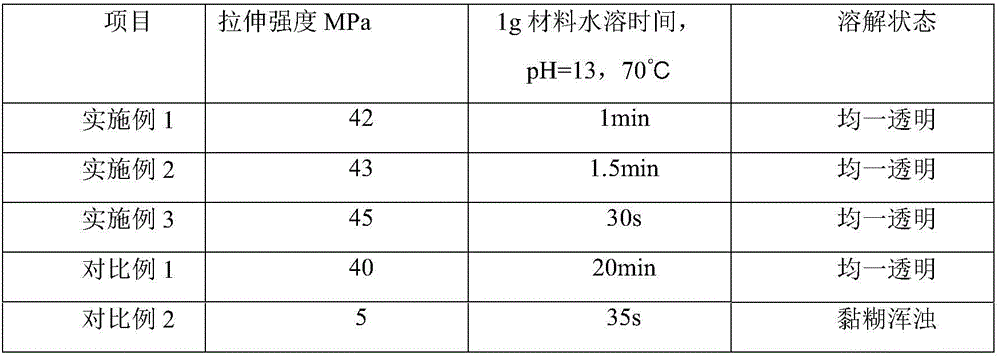

Examples

Embodiment 1

[0027] Step S11: Add 2Kg of acrylonitrile, 1Kg of acrylic acid, 1Kg of methacrylic acid, 2Kg of vinyl acetate, 20g of azobisisobutyronitrile, and 10Kg of toluene into the reaction vessel, stirring continuously, under the condition of constant temperature of 150°C, condensation and reflux After 5 hours of reaction, a pre-neutralized polymer was obtained.

[0028] Step S12: Add 60 g of sodium hydroxide to the pre-neutralized polymer, stir continuously, and react at normal temperature and pressure for 0.5 h to obtain a neutralized polymer.

[0029] Step S13: The neutralized polymer was rotary evaporated for 0.2 h at a temperature of 40° C. and a pressure of −0.1 MPa to obtain a neutralized polymer from which the solvent was removed.

[0030] Step S14: drying the neutralized polymer at 60° C. for 48 hours to obtain a solid neutralized polymer.

[0031] Step S15: Mix 5Kg of neutralizing polymer, 1.25g of antioxidant 1010, 1.25g of antioxidant 168, and 2.5g of calcium stearate, and...

Embodiment 2

[0033] Step S21: Add 2Kg of divinylbenzene, 2Kg of methacrylic acid, 2Kg of ethyl acrylate, 2Kg of vinyl acetate, 100g of ammonium persulfate, and 1Kg of ethyl acetate into the reaction vessel, keep stirring, keep the temperature at 65°C, condense and reflux Under the condition of reacting for 24h, the pre-neutralized polymer was obtained.

[0034] Step S22: Dissolve 800g of lithium hydroxide in 16Kg of ethyl acetate, slowly add to the pre-neutralized polymer, stir continuously, and react at normal temperature and pressure for 24 hours to obtain the neutralized polymer.

[0035] Step S23: The neutralized polymer was rotated and evaporated for 8 hours at a temperature of 90° C. and a pressure of −0.05 MPa to obtain a neutralized polymer from which the solvent was removed.

[0036] Step S24: drying the neutralized polymer at a temperature of 150° C. for 2 hours to obtain a solid neutralized polymer.

[0037] Step S25: Mix 5Kg of neutralizing polymer, 12.5g of antioxidant 1076, ...

Embodiment 3

[0039] Step S31: Add 2Kg of styrene, 2Kg of methacrylic acid, 2Kg of butyl acrylate, 2Kg of vinyl acetate, 48g of benzoyl peroxide, and 2Kg of ethanol into the reaction vessel, stir continuously, and keep the temperature at 80°C, condensing and refluxing Under the reaction for 8h, the pre-neutralized polymer was obtained.

[0040] Step S32: Dissolving 240g of potassium hydroxide in 2Kg of ethanol, slowly adding to the pre-neutralized polymer, stirring constantly, and reacting at normal temperature and pressure for 1 hour to obtain the neutralized polymer.

[0041] Step S33: The neutralized polymer was rotary evaporated for 3 hours at a temperature of 50° C. and a pressure of −0.08 MPa to obtain a neutralized polymer from which the solvent was removed.

[0042] Step S34: drying the neutralized polymer at a temperature of 120° C. for 8 hours to obtain a solid neutralized polymer.

[0043] Step S35: Mix 5Kg of neutralizing polymer, 5g of antioxidant 1010, 5g of antioxidant 168, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com