MoS2 inserted-layer Ti3C2 lithium ion battery negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of improving electrochemical performance that have not been reported publicly, and achieve excellent electrochemical performance, open structure, interlayer spacing Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

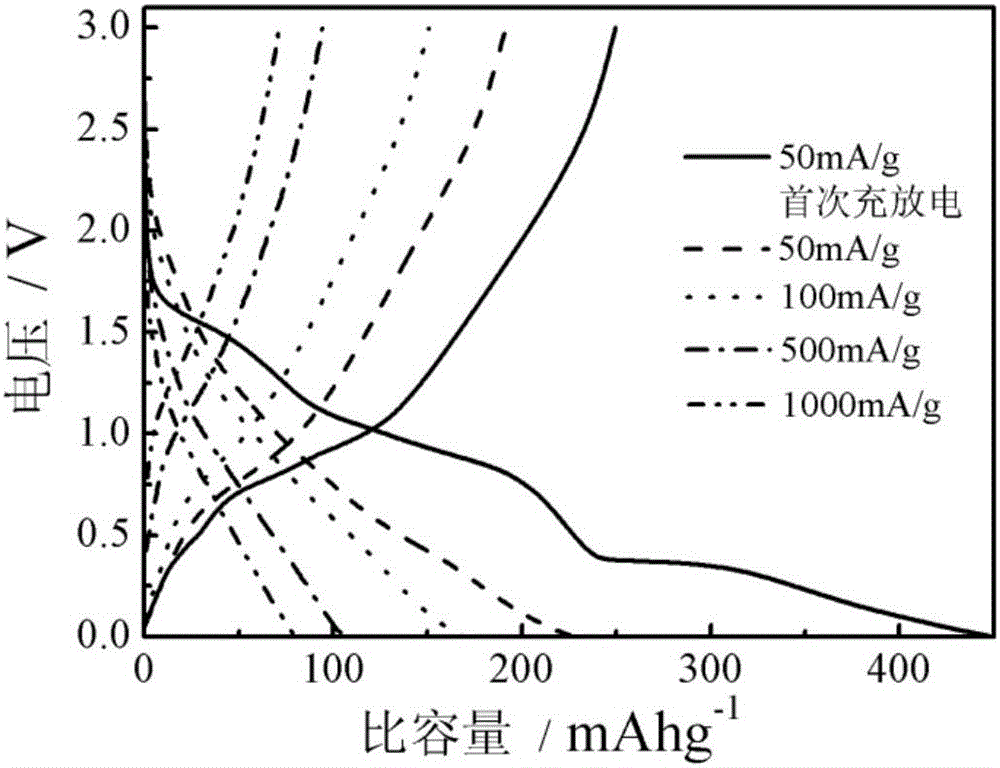

Embodiment 1

[0032] (1) Put Ti 3 AlC 2 Add 0.05 grams per milliliter of solution to a 49% hydrofluoric acid solution, stir at room temperature for 24 hours, then centrifuge the mixed solution to precipitate, and rinse the precipitate with deionized water 7 times until rinsed The pH value of the solution of the precipitate reaches 5.5, and then the obtained precipitate is placed in a vacuum drying box and dried at 80 ° C for 12 hours to obtain Ti. 3 C 2 powder;

[0033] (2) first, sodium molybdate dihydrate is added to the ethanol solution according to the ratio of adding 0.00022 grams per milliliter of solution, and after being completely dissolved, the Ti obtained in step (1) is added according to the ratio of adding 0.01428 grams per milliliter of solution. 3 C 2 powder, stir evenly; finally, add L-cysteine at a rate of 0.00022 g per ml of solution, stir evenly, and ultrasonically disperse for 1 hour to promote the solution to enter Ti 3 C 2 between layers;

[0034] The above mi...

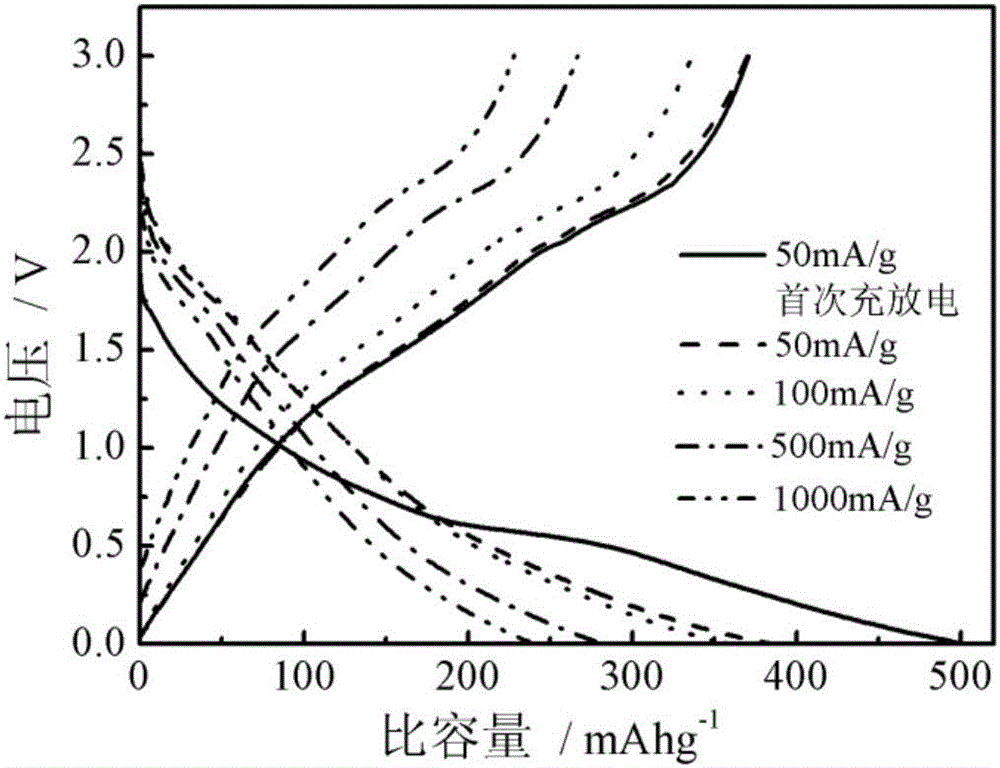

Embodiment 2

[0037] (1) Put Ti 3 AlC 2 Add 0.05 grams per milliliter of solution to a 49% hydrofluoric acid solution, stir at room temperature for 24 hours, then centrifuge the mixed solution to precipitate, and rinse the precipitate with deionized water 7 times until rinsed The pH value of the solution of the precipitate reaches 5.5, and then the obtained precipitate is placed in a vacuum drying box and dried at 80 ° C for 12 hours to obtain Ti. 3 C 2 powder;

[0038] (2) firstly molybdenum trioxide was added to the ethanol solution according to the ratio of adding 0.00013 grams per milliliter of solution, and after being completely dissolved, the Ti obtained in step (1) was added in the ratio of adding 0.01428 grams per milliliter of solution. 3 C 2 powder, stir evenly; finally, add thioacetamide at a rate of 0.00014 grams per milliliter of solution, stir evenly, and ultrasonically disperse for 1 hour to promote the solution to enter the Ti 3 C 2 between layers;

[0039] The above...

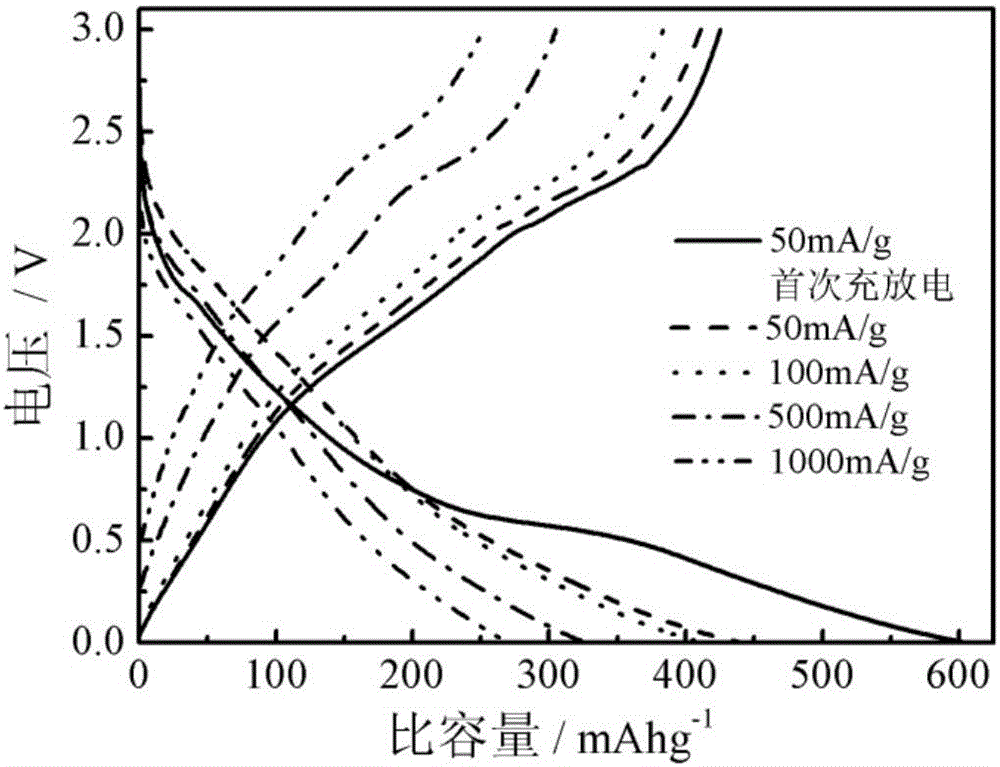

Embodiment 3

[0042] (1) Put Ti 3 AlC 2 Add 0.05 grams per milliliter of solution to a 49% hydrofluoric acid solution, stir at room temperature for 24 hours, then centrifuge the mixed solution to precipitate, and rinse the precipitate with deionized water 7 times until rinsed The pH value of the solution of the precipitate reaches 5.5, and then the obtained precipitate is placed in a vacuum drying box and dried at 80 ° C for 12 hours to obtain Ti. 3 C 2 powder;

[0043] (2) first add ammonium molybdate tetrahydrate to the ethanol solution according to the ratio of adding 0.00016 grams per milliliter of solution, after being completely dissolved, then add the Ti obtained in step (1) according to the ratio of adding 0.01428 grams per milliliter of solution 3 C 2 powder, stir evenly; finally, add thiourea at a rate of 0.00014 grams per milliliter of solution, stir evenly, and ultrasonically disperse for 1 hour to promote the solution into Ti 3 C 2 between layers;

[0044] The above mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com