High viable bacterium natto tablets and preparation method thereof

A technology of natto flakes and natto with high viable bacteria is applied in the directions of food ingredients as antioxidants, food ingredients as taste modifiers, food ingredients as odor modifiers, etc., and can solve problems such as being unsuitable for high viable bacteria natto chips. , to overcome the special smell and sticky taste, the effect of high natto viable count

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

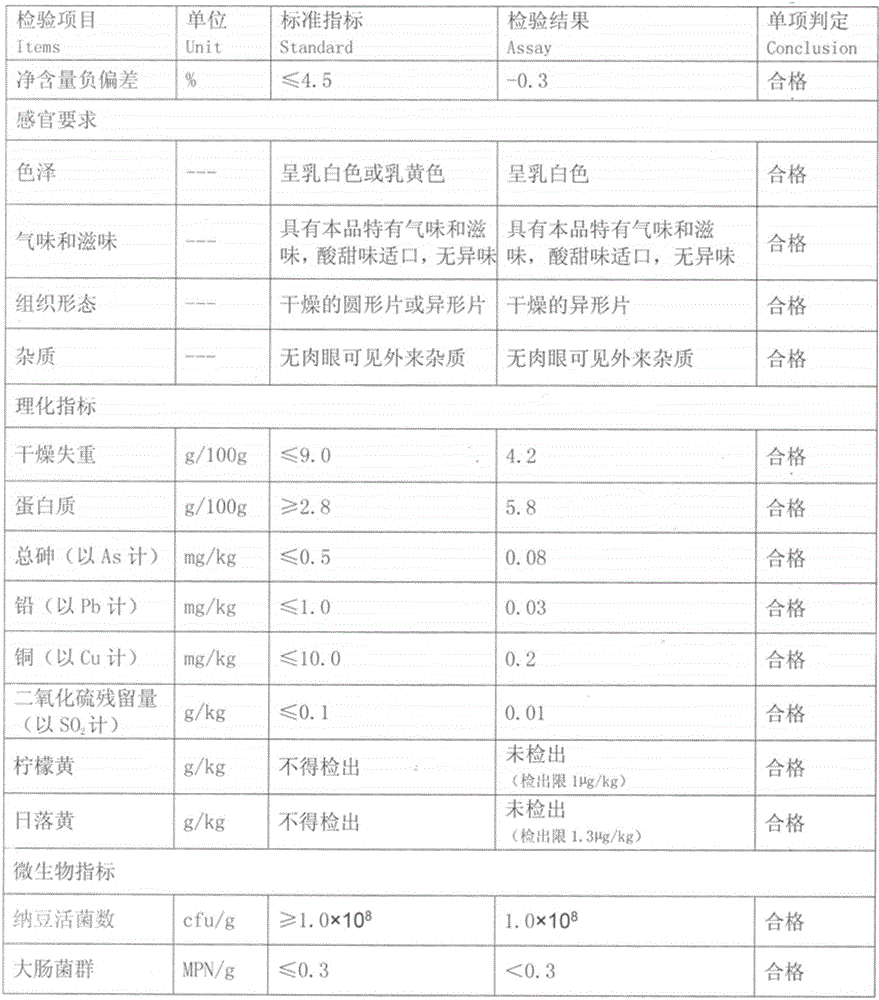

Examples

Embodiment 1

[0071] 1) Preparation of natto premix by mixing ingredients at one time: First, weigh 50 parts of natto freeze-dried powder, 2 parts of microcrystalline cellulose, 6 parts of konjac powder, 2 parts of soybean protein powder, and pectin according to the mass formula ratio. 2 parts, 0 parts of edible gelatin, 3 parts of sucrose fatty acid ester, 0 part of β-cyclodextrin, 0.5 part of sodium tripolyphosphate, and then pre-mix once by stirring, then add 6 parts of phospholipids and octenyl succinic acid The mixture of 6 parts of starch sodium is then pre-mixed for the second time by stirring, and finally the raw and auxiliary materials are evenly mixed by a 16-purpose pendulum granulator to make a natto premix.

[0072] 2) Prepare the natto mixture by mixing the secondary ingredients: first, weigh 0 parts of pregelatinized starch, 0 parts of isomalto-oligosaccharide, 0 parts of white sugar, 0 parts of edible glucose and 4 parts of xylitol according to the mass formula ratio , 0.6 p...

Embodiment 2

[0088] 1) Preparation of natto premix by mixing ingredients at one time: First, weigh 40 parts of natto freeze-dried powder, 2 parts of microcrystalline cellulose, 6 parts of konjac powder, 1.8 parts of soybean protein powder, and pectin according to the mass formula ratio. 1.8 parts, 0 parts of edible gelatin, 3 parts of sucrose fatty acid ester, 1 part of β-cyclodextrin, 0.5 parts of sodium tripolyphosphate, and then premixed once by stirring, and then added 6 parts of phospholipids and octenyl succinic acid The mixture of 6 parts of starch sodium is then pre-mixed for the second time by stirring, and finally the raw and auxiliary materials are mixed evenly by a 16-purpose pendulum granulator to make a natto premix.

[0089] 2) Secondary ingredients are mixed to prepare natto mixture: first, according to the mass formula ratio, weigh 5 parts of pregelatinized starch, 5 parts of isomalto-oligosaccharide, 0 part of white granulated sugar, 0 part of edible glucose, and 4 parts o...

Embodiment 3

[0105] 1) Prepare the natto premix by mixing the ingredients at one time: first, weigh 30 parts of natto freeze-dried powder, 2 parts of microcrystalline cellulose, 6 parts of konjac fine powder, 1.8 parts of soybean protein powder, and pectin according to the mass formula ratio. 1.8 parts, 0 parts of edible gelatin, 3 parts of sucrose fatty acid ester, 1 part of β-cyclodextrin, 0.5 parts of sodium tripolyphosphate, and then premixed once by stirring, and then added 6 parts of phospholipids and octenyl succinic acid The mixture of 6 parts of starch sodium is then pre-mixed for the second time by stirring, and finally the raw and auxiliary materials are mixed evenly by a 16-purpose pendulum granulator to make a natto premix.

[0106] 2) Preparation of natto mixture by mixing secondary ingredients: First, weigh 10 parts of pregelatinized starch, 10 parts of isomalto-oligosaccharide, 0 part of white sugar, 0 part of edible glucose and 4 parts of xylitol according to the ratio of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com