Graphene/anionic polysaccharide composite microsphere carrier and preparation method thereof

A technology of composite microspheres and graphene, applied in the direction of microcapsules, nanocapsules, pharmaceutical formulations, etc., can solve the problems of rapid disintegration of carrier structures, low bioavailability, and difficulty in controlled release, and achieve slow and reliable drug release rates. control, widely promote the application value, and enhance the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

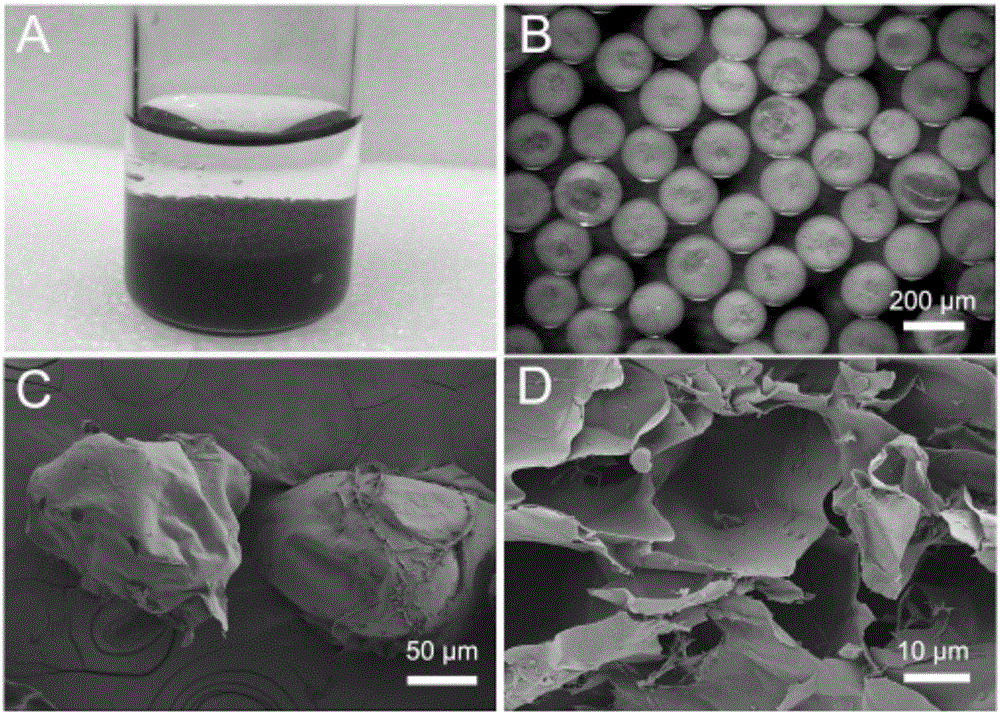

[0037] At room temperature (25°C), add graphene oxide (GO) and carboxymethyl chitosan (CMCS) into deionized water, ultrasonically blend evenly, feed CMCS: 50mg / mL, GO: 5mg / mL; Driven by a micro-injection pump (3mL / h), the CMCS / GO mixed solution enters the electrostatic field (electric field voltage 10kV, plate distance 20cm) through a metal nozzle (Φ=250μm) and disperses into small droplets; Physical cross-linking and curing take place in the process. After centrifugation and purification, microspheres with a particle size better than 200 μm can be obtained. That is graphene oxide / carboxymethyl chitosan composite microspheres. The particle size and distribution of the product microspheres are regulated by the feed ratio and proportion of CMCS and GO, the injection speed and the electrostatic field force. The result is as figure 1 shown.

[0038] figure 1 It is the morphology characterization of graphene oxide / carboxymethyl chitosan (GO / CMCS) composite microspheres: (A) Ap...

Embodiment 2

[0042] At room temperature (25°C), add graphene oxide (GO) and sodium alginate (ALG) into deionized water, ultrasonically blend evenly, feed ALG: 40mg / mL, GO: 5mg / mL; Driven by (3mL / h), the ALG / GO mixed solution enters the electrostatic field (electric field voltage 10kV, plate distance 20cm) through the metal nozzle (Φ=250μm), and disperses into small droplets; Cross-linking, curing and forming. After centrifugation and purification, microspheres with a particle size better than 200 μm can be obtained. That is graphene oxide / sodium alginate composite microspheres. The particle size and distribution of the product microspheres are regulated by the feed ratio and proportion of ALG and GO, the injection speed and the electrostatic field force.

[0043]In the drug loading and in vitro release experiments, the product microspheres can effectively adsorb the model drug - Gatifloxacin (GFLX), and the drug loading can reach up to 0.28 mg / mg, which is higher than that of pure seawee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com