A slow-release anti-corrosion microcapsule applied to reinforced concrete and its preparation method

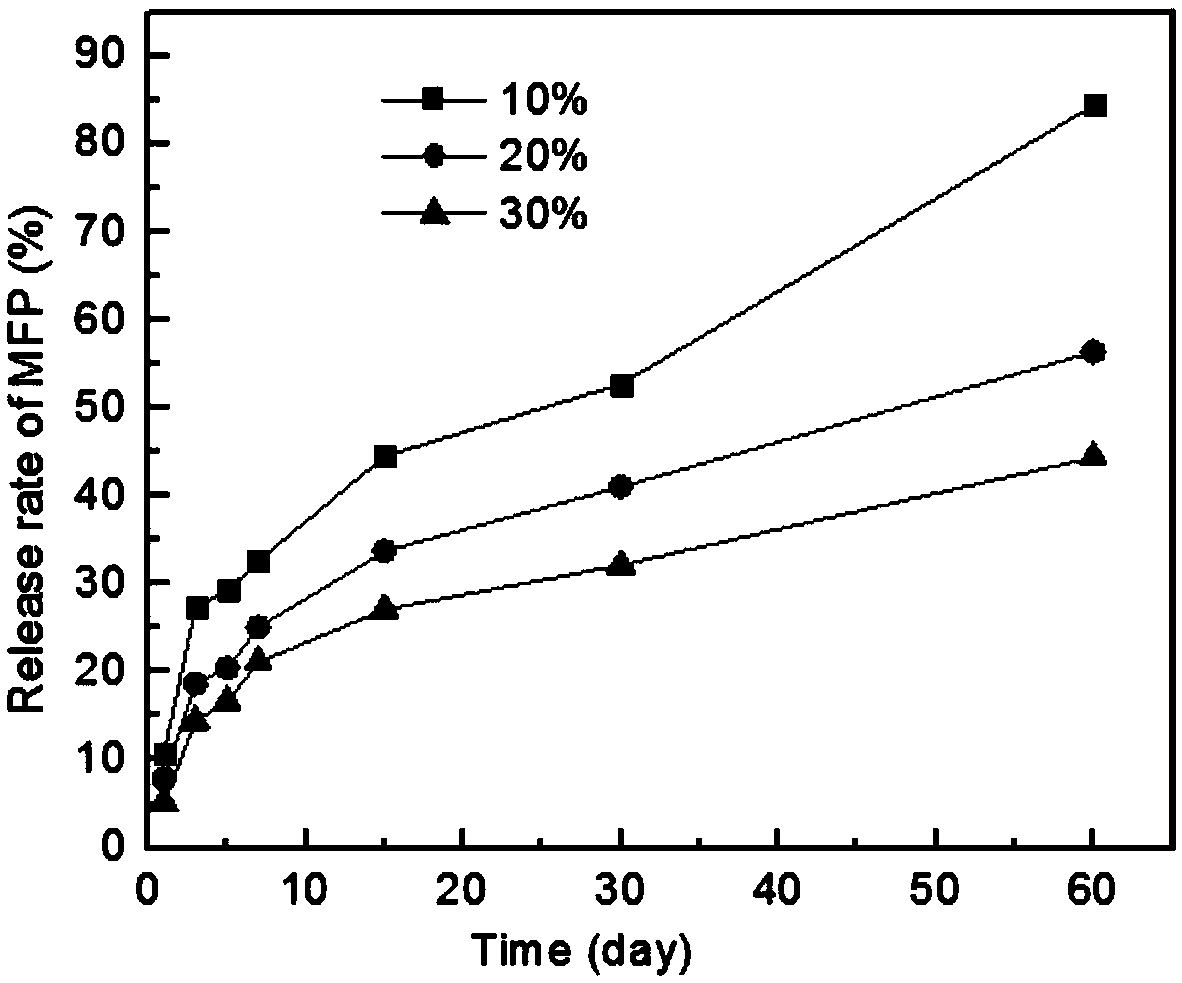

A reinforced concrete and microcapsule technology, applied in the field of materials, can solve the problems of large size, high temperature and damage, and achieve the effects of high utilization rate of raw materials, wide size regulation range and controllable release rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

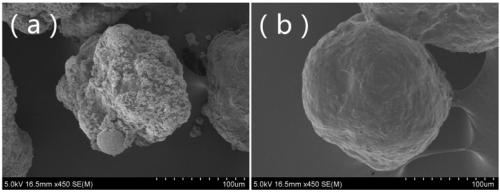

[0069] The preparation method of ethyl cellulose / sodium monofluorophosphate antirust microcapsules comprises the following steps:

[0070] 1) Preparation of core material by centrifugation: Mix 1000g of sodium monofluorophosphate and auxiliary materials according to the ratio in Table 1, then add them to the centrifugal equipment, turn on the blower in turn, the blower speed is 400r / min, the turntable speed is 600r / min, and the peristaltic pump is turned on For liquid supply, the peristaltic pump speed is 10r / min, and the liquid supply volume is 300ml. When the material flows in flocculent form in the pot, turn off the peristaltic pump, continue to rotate, polish, take out and dry when the particle size and hardness meet the requirements, and obtain the core material.

[0071] 2) Coating solution preparation: add ethyl cellulose into ethyl acetate according to the ratio in Table 2, and prepare a transparent and uniform coating solution under heating and stirring with a magneti...

Embodiment 2

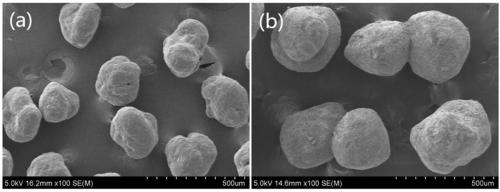

[0075] The preparation method of polystyrene / calcium nitrite antirust microcapsules comprises the following steps:

[0076] 1) Prepare the core material by centrifugation: mix 1000g of calcium nitrite and auxiliary materials according to the ratio in Table 1, then add them to the centrifugal equipment, turn on the blower in turn, the blower speed is 400r / min, the turntable speed is 500r / min, turn on the peristaltic pump to supply Peristaltic pump speed is 10r / min, and the liquid supply volume is 400ml. Turn off the peristaltic pump when the material flows in flocculent shape in the pot, continue to rotate, polish, take out and dry when the particle size and hardness meet the requirements, and obtain the core material .

[0077] 2) Coating solution preparation: polystyrene was added into ethyl acetate according to the ratio in Table 2, and a transparent and uniform coating solution was prepared under heating and stirring with a magnetic stirrer.

[0078] 3) Fluidized bed coati...

Embodiment 3

[0080] The preparation method of polycarbonate / cerium nitrate antirust microcapsules comprises the following steps:

[0081] 1) Prepare the core material by centrifugation: mix 1000g of cerium nitrate according to the ratio in Table 1 and add it to the centrifugal equipment, turn on the blower in turn, the blower speed is 500r / min, the turntable speed is 400r / min, turn on the peristaltic pump to supply liquid, and the peristaltic The pump speed is 20r / min, and the liquid supply volume is 400ml. When the material flows in flocculent form in the pot, turn off the peristaltic pump, continue to rotate, polish, and take out and dry when the size and hardness of the particles meet the requirements to obtain the core material.

[0082] 2) Coating solution preparation: polycarbonate was added into ethyl acetate according to the ratio in Table 2, and a transparent and uniform coating solution was prepared under heating and stirring with a magnetic stirrer.

[0083] 3) Fluidized bed coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com