Catalyst for low-temperature synergistic degradation of dioxin and NOx and preparation method for catalyst

A technology of synergistic degradation and catalyst, applied in the direction of chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of dioxin and NOx purification effect and unexplained use temperature range, and achieve improvement Effect of redox ability, high mechanical strength, good sulfur resistance and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

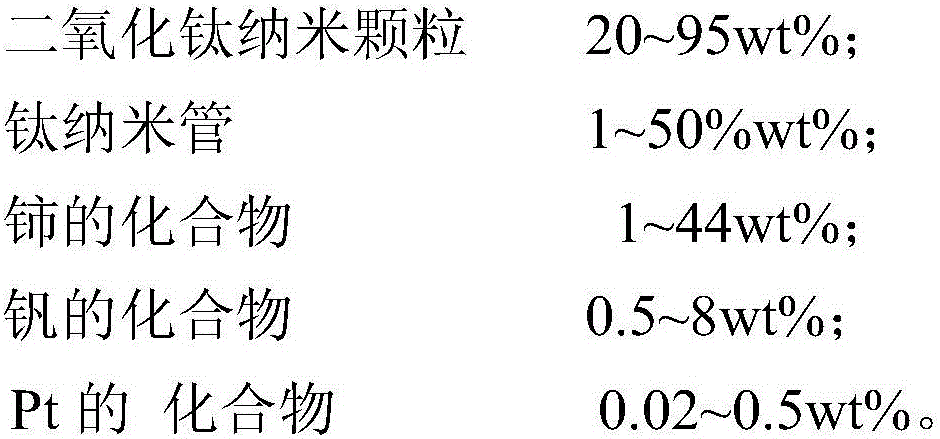

[0056] Weigh 59 grams of titanium dioxide nanoparticles and 30 grams of titanium nanotubes, add excess water for impregnation, stir and mix evenly to obtain a catalyst carrier; finally dissolve 22.45 grams of cerium nitrate, 2.57 grams of ammonium metavanadate, and 0.21 grams of chloroplatinic acid in 80 ° C Prepare a solution in deionized water, add the above-mentioned catalyst carrier under strong stirring, continue stirring for 12 hours, then dry it, and finally bake it at 400°C for 3 hours.

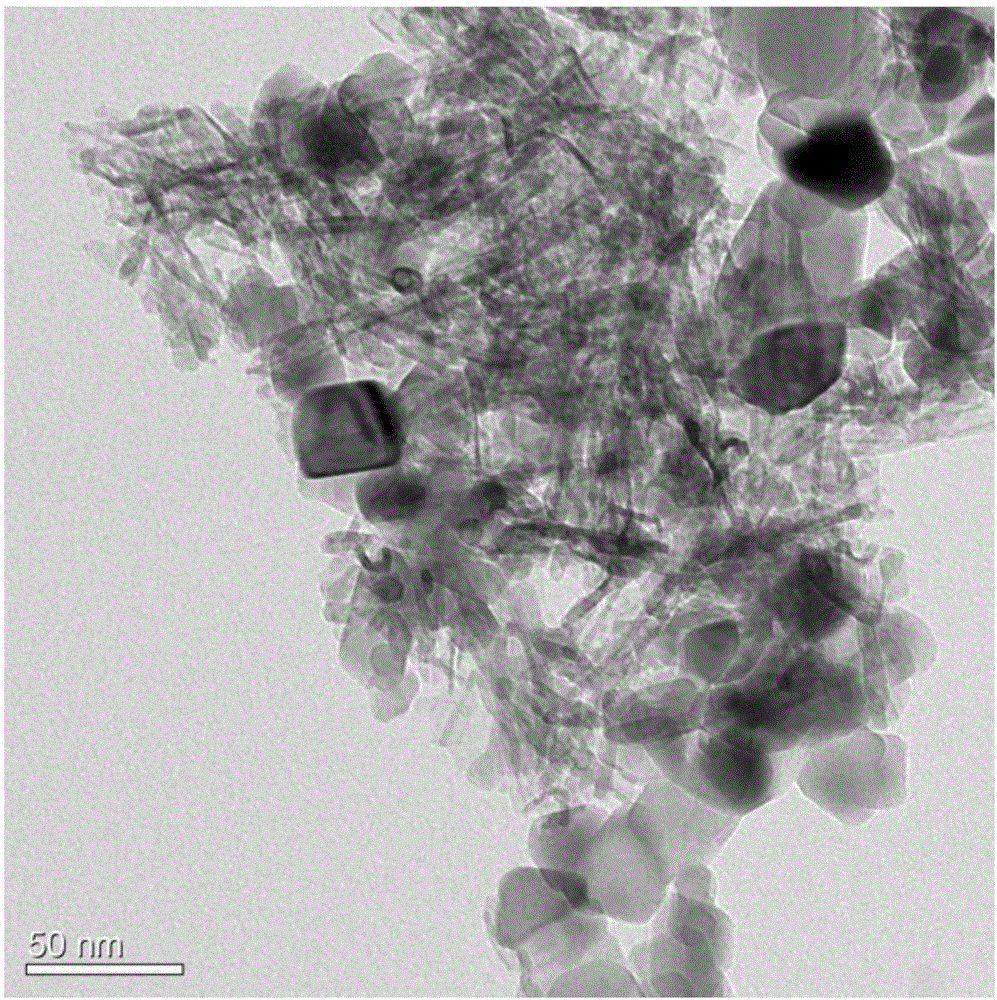

[0057] Embodiment 1 makes the transmission electron microscope figure of catalyst such as figure 1 shown.

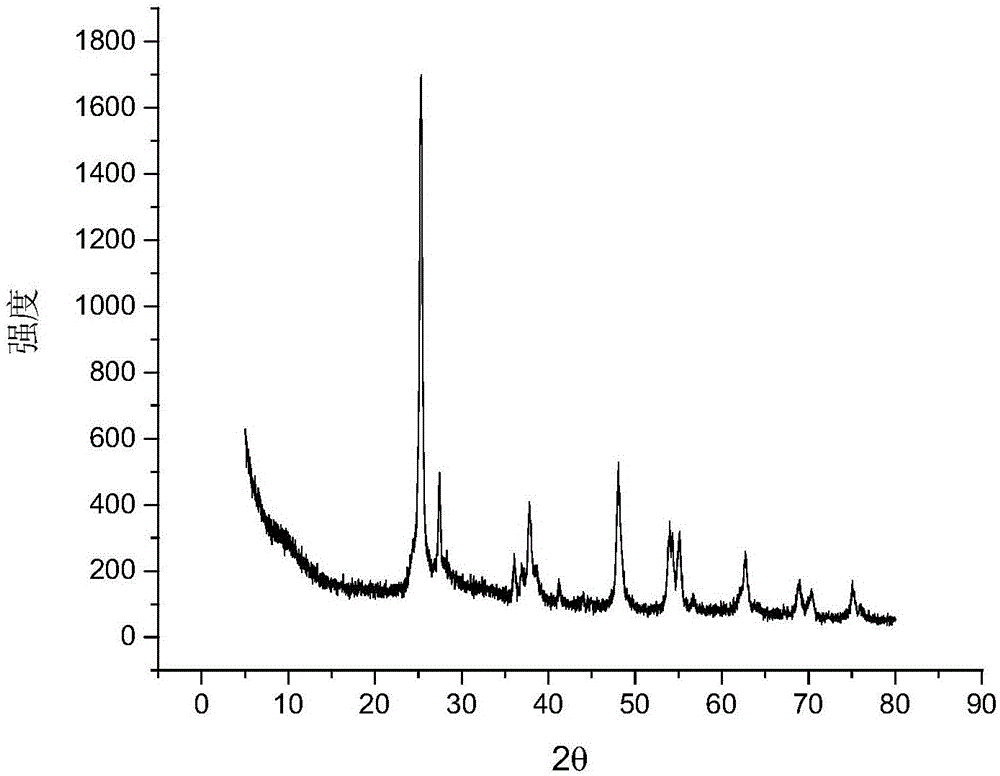

[0058] Embodiment 1 makes the XRD spectrogram of catalyst support such as figure 2 shown.

Embodiment 2

[0060] Weigh 22 grams of titanium dioxide nanoparticles and 50 grams of titanium nanotubes, add excess water for impregnation, stir and mix evenly to obtain a catalyst carrier; finally dissolve 20 grams of cerium oxide, 8 grams of vanadium pentoxide, and 0.1 gram of chloroplatinic acid at 60 ° C Prepare a solution in deionized water, add the above-mentioned catalyst carrier under strong stirring, continue to stir for 4 hours, then dry it, and finally bake it at 350°C for 3 hours.

Embodiment 3

[0062] Weigh 98 grams of titanium dioxide nanoparticles and 2 grams of titanium nanotubes, add excess water for impregnation, stir and mix evenly to obtain a catalyst carrier; finally dissolve 2.52 grams of cerium nitrate, 0.63 grams of ammonium metavanadate, and 0.25 grams of chloroplatinic acid at 80 ° C. Prepare a solution in deionized water, add the above-mentioned catalyst carrier under strong stirring, continue stirring for 12 hours, then dry it, and finally bake it at 600°C for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com