Compound 1, 5-trimellitic anhydride glutarate and compounding method thereof

A technology of pentadiyl trimellitic anhydride and trimellitic anhydride acid chloride, which is applied in the direction of organic chemistry, can solve the problems of adverse effects on various properties of materials, poor molding processability, high curing temperature, etc., and achieve the maintenance of mechanical properties and thermal stability, and good heat resistance Sexuality and electrical performance, the effect of short working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

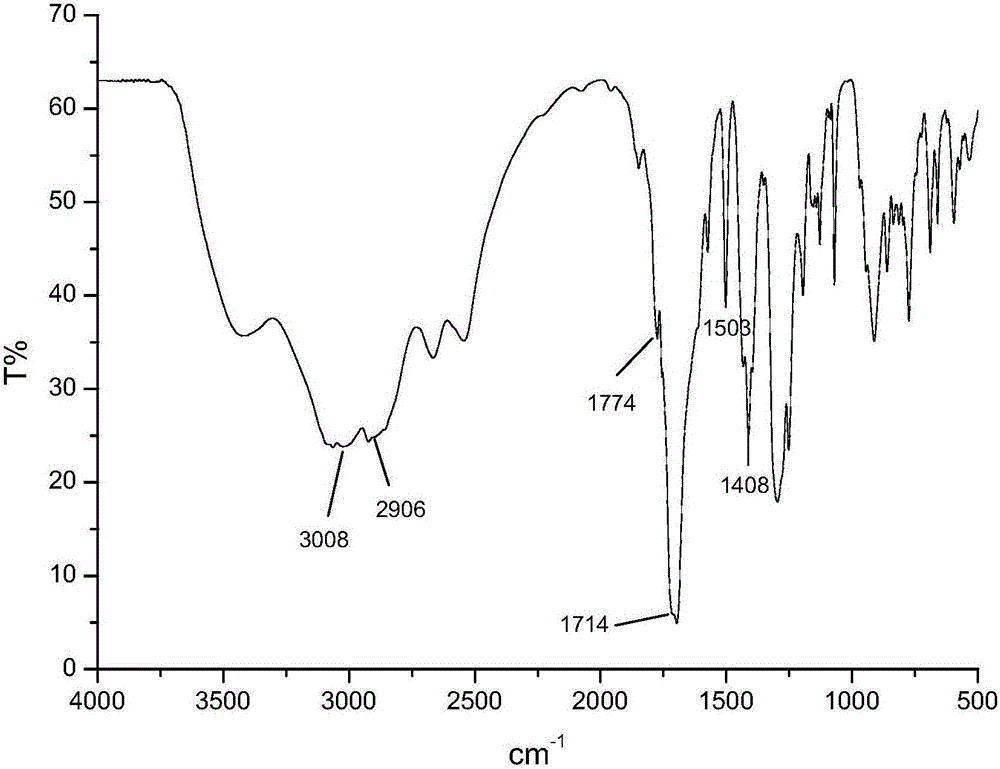

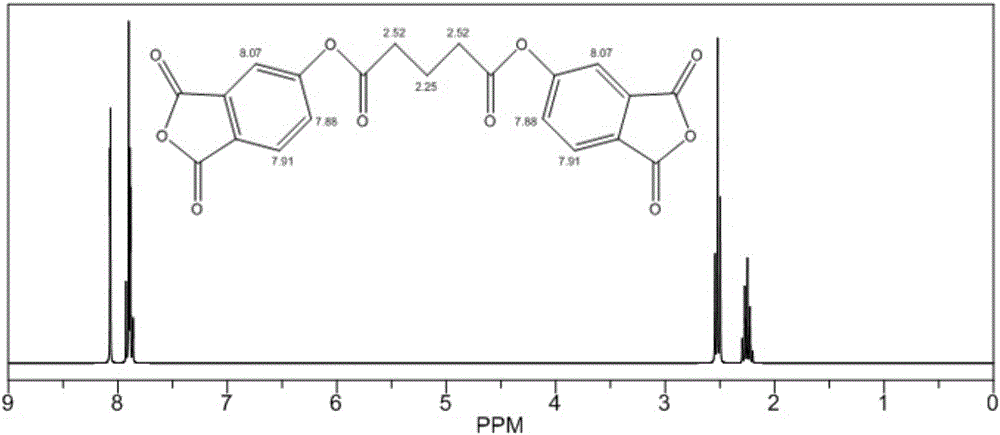

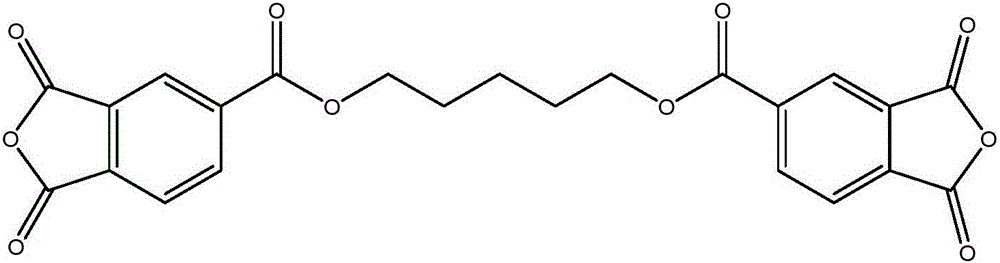

[0027] Compound 1,5-pentamellitic anhydride, its molecular structural formula is as follows:

[0028]

[0029] The synthetic method of above-mentioned compound 1,5-pentamellitic anhydride, concrete steps are as follows:

[0030] (1) Prepare ice salt according to the mass ratio of ice: calcium chloride hexahydrate = 100:20, and take trimellitic anhydride acid chloride, 1,5-pentanediol, DBU, and solvent 1,2-di Ethyl chloride is 5 times the volume of the reactant;

[0031] Put the weighed trimellitic anhydride acid chloride into the solvent ethyl acetate, start the magnetic stirrer, first dissolve the trimellitic anhydride acid chloride in ethyl acetate, then place the weighed 1,5-pentanediol in the dropper, slowly drop it within 25min After completion, the reaction solution was obtained; DBU was added to the above reaction solution within 30 minutes, and then the reaction temperature was controlled at -5 to 0°C (the reaction was carried out in an ice-salt bath environment to...

Embodiment 2

[0039] The synthetic method of compound 1,5-pentamellitic anhydride, concrete steps are as follows:

[0040] (1) Prepare ice salt according to the mass ratio of ice: sodium chloride = 100:33, and take trimellitic anhydride acid chloride, 1,5-pentanediol, and pyridine in a molar ratio of 1:0.4:2; the solvent is ethyl acetate as the reactant 7 times the volume;

[0041] Put the weighed trimellitic anhydride acid chloride into the solvent dimethyl sulfoxide, start the magnetic stirrer, first dissolve the trimellitic anhydride acid chloride in dimethyl sulfoxide; then put the weighed 1,5-pentanediol and pyridine into the dropper Shake well, slowly drop into the reaction system within 30 minutes, then control the reaction temperature at -5~0°C (the reaction is carried out in an ice-salt bath environment to maintain the low temperature required for the reaction), react for 4 hours, the reaction system is white paste, That is, the crude product of pentamethylene ditrimellitic anhydr...

Embodiment 3

[0045] The synthetic method of compound 1,5-pentamellitic anhydride, concrete steps are as follows:

[0046](1) According to the mass ratio of ice:ammonium nitrate=100:10, ice salt is prepared, and the molar ratio is 1:0.5:2.5 to get trimellitic anhydride acid chloride, 1,5-pentanediol, ammonia water (28wt%), and the solvent dichloromethane is 8 times the volume of the reactant;

[0047] Put the weighed trimellitic anhydride acid chloride into the solvent methylene chloride, start the magnetic stirrer, first dissolve the trimellitic anhydride acid chloride in the methylene chloride, then place the weighed 1,5-pentanediol in the dropper, and slowly drop it within 15 minutes After completion, the reaction solution is obtained; put ammonia water into the above reaction solution, and then add ice salt to the water bath to control the reaction temperature at -5 ~ 0°C, and react for 5 hours. The resulting solution is white, which is 1,5-dimellitate anhydride crude product;

[0048...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com