A kind of biodegradable plastic resin and its preparation process

A technology of biodegradable plastics and preparation process, which is applied in the field of biodegradable plastic resins and its preparation, which can solve the problems of difficult photodegradation and achieve the effects of short degradation time, improved tensile strength, and increased plastic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

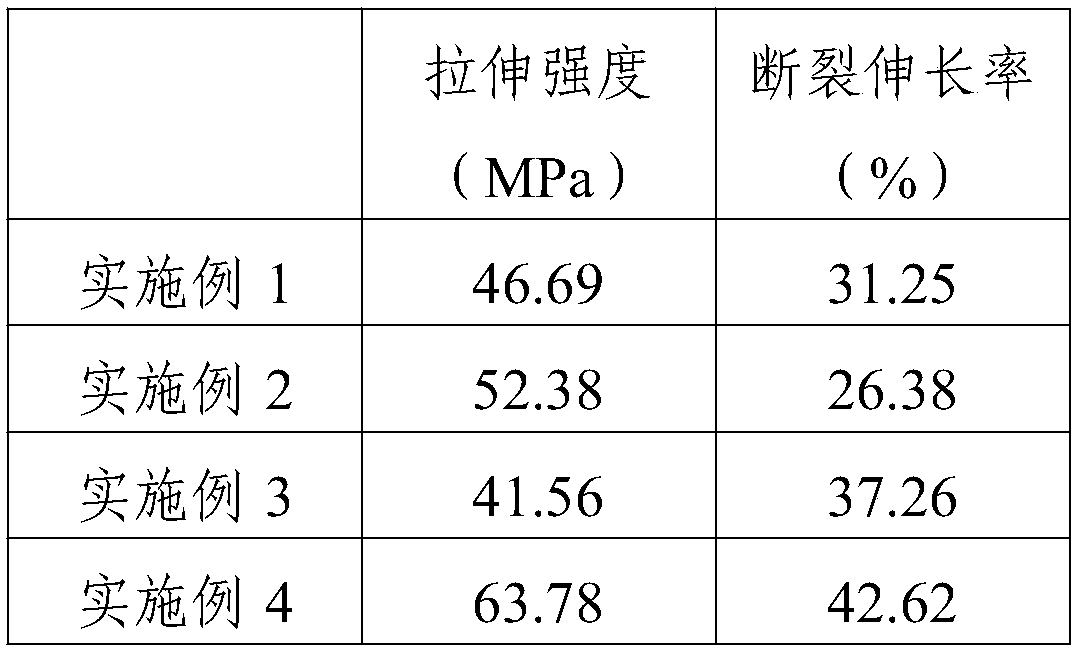

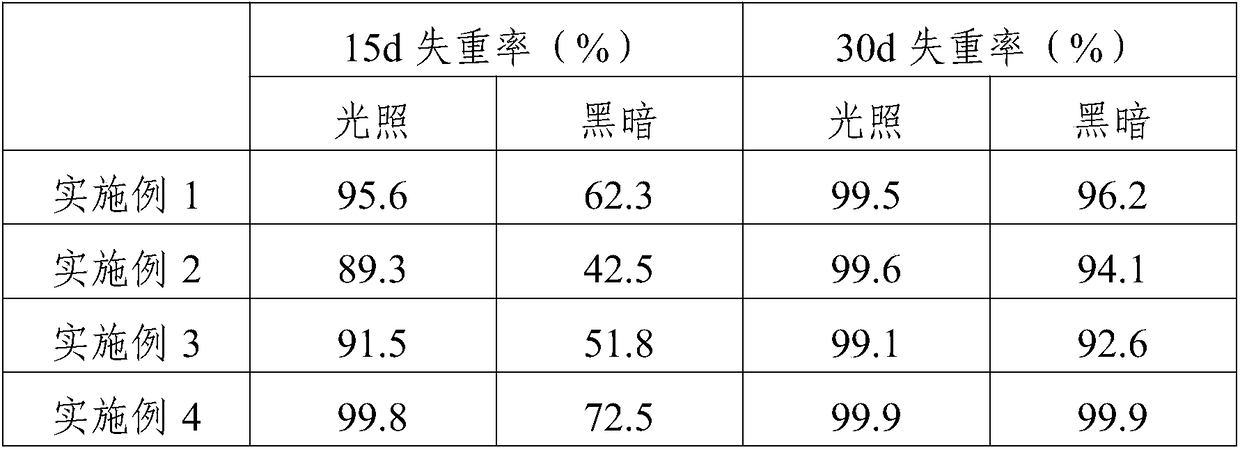

Examples

Embodiment 1

[0022] A biodegradable plastic resin, consisting of the following parts by weight: 80 parts of polylactic acid, 50 parts of polyvinyl alcohol, 60 parts of modified starch, 20 parts of cellulose, 15 parts of glycerin, 12 parts of maleic anhydride, graphene 15 parts, 25 parts of chitosan, 6 parts of Ce-modified titanium dioxide, and 8 parts of photocatalyse. The diameter of the Ce-modified titanium dioxide is 40-50 nm.

[0023] The preparation technology of described biodegradable plastic resin, comprises the following steps:

[0024] (1) Add cyclohexane and ethanol to the mixture of starch, stir evenly, microwave for 2 hours, heat up to 80°C, slowly add hydrochloric acid and potassium permanganate, and keep warm for 1 hour;

[0025] (2) Add sodium hydroxide solution to the mixing system in step (1), adjust the pH to 10, adjust the system temperature to 70°C, add polylactic acid and polyvinyl alcohol to ultrasonic for 30 minutes, then add maleic anhydride, and raise the temperat...

Embodiment 2

[0029] A biodegradable plastic resin, consisting of the following parts by weight: 80 parts of polylactic acid, 80 parts of polyvinyl alcohol, 50 parts of modified starch, 10 parts of cellulose, 28 parts of glycerin, 12 parts of maleic anhydride, Ketjen 10 parts of carbon black, 15 parts of chitosan, 15 parts of Ce-modified titanium dioxide, and 5 parts of photocatalystase. The diameter of the Ce-modified titanium dioxide is 40-50 nm.

[0030] The preparation technology of described biodegradable plastic resin, comprises the following steps:

[0031] (1) Add ethyl acetate to the starch, stir evenly, microwave for 2.5 hours, heat up to 70-90°C, slowly add hydrochloric acid and potassium permanganate, and keep warm for 2 hours;

[0032] (2) Add sodium hydroxide solution to the mixing system in step (1), adjust the pH to 12, adjust the system temperature to 60°C, add polylactic acid and polyvinyl alcohol to ultrasonic for 60 minutes, then add maleic anhydride, and raise the tempe...

Embodiment 3

[0036] A biodegradable plastic resin, consisting of the following parts by weight: 100 parts of polylactic acid, 70 parts of polyvinyl alcohol, 30 parts of modified starch, 25 parts of cellulose, 22 parts of glycerin, 15 parts of maleic anhydride, carbon nano 8 parts of tubes, 20 parts of chitosan, 10 parts of Ce-modified titanium dioxide, and 3 parts of photocatalyse. The diameter of the Ce-modified titanium dioxide is 30-40 nm.

[0037] The preparation technology of described biodegradable plastic resin, comprises the following steps:

[0038] (1) Add acetone to the starch, stir evenly, microwave for 3 hours, heat up to 70°C, slowly add hydrochloric acid and potassium permanganate, and keep warm for 3 hours;

[0039] (2) Add sodium hydroxide solution to the mixing system in step (1), adjust the pH to 10, adjust the system temperature to 50°C, add polylactic acid and polyvinyl alcohol to ultrasonic for 30 minutes, then add maleic anhydride, and raise the temperature to 120°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com