A LED epitaxial structure with stress compensation effect barrier layer

A technology of stress compensation and epitaxial structure, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of high background concentration, lower electromotive injection efficiency, lower recombination efficiency, etc., to increase the barrier height, improve internal quantum efficiency, The effect of improving compound efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

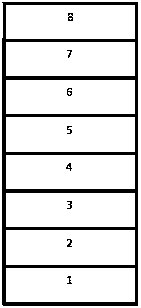

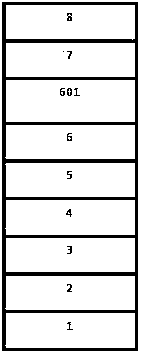

[0019] The preparation method of the structure of the present invention is to perform high-temperature baking in an MOCVD reaction furnace to remove residual impurities on the surface of the patterned substrate 1 , and slowly lower the temperature between 500-900° C. to grow a layer of AlN buffer layer 2 . Then the temperature is raised rapidly, and the U-shaped GaN layer 3 is grown at 900-1200° C. for about 10-80 minutes, with a thickness of 1-10 um. After that, the N-type GaN layer 4 is grown at a growth temperature of 800-1200° C., a growth time of 10-80 min, and a total growth thickness of 10-10000 nm. The shallow quantum well 5 is grown at a growth temperature of 680-880° C. and a total growth thickness of 10 nm-2000 nm. The active region 6 is grown at a growth temperature of 680-880°C, with a total growth thickness of 10nm-2000nm. A stress compensation layer 601 is grown. The electron blocking layer 7 is grown at 800-1000° C. with a thickness of 50-1000 angstroms. Re-...

Embodiment 1

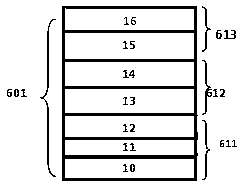

[0022] ① First grow the U-GaN layer 10, the growth temperature is 700°C, the growth pressure is 200mbar,

[0023] The growth thickness is 1nm; the growth temperature of U-AlGaN layer 11 is 700°C, the growth pressure is 200mbar, the growth thickness is 1nm, and the Al composition is 0.1; the growth temperature of U-InGaN layer 12 is 700°C, the growth pressure is 200mbar, and the growth thickness is 1nm, In composition 0.02.

[0024] ②Secondly, grow the N-AlGaN layer 13 at a growth temperature of 700°C, a growth pressure of 200mbar, a growth thickness of 1nm, an Al composition of 0.1, and a Si doping concentration of 5×10 17 ; The growth temperature of N-InGaN layer 14 is 700°C, the growth pressure is 200mbar, the growth thickness is 1nm, the In composition is 0.02, and the Si doping concentration is 5×10 17 .

[0025] ②Finally, grow the P-AlGaN layer 15 at a growth temperature of 700°C and a growth pressure of

[0026] 200mbar, the growth thickness is 1nm, the Al component i...

Embodiment 2

[0028] ① First grow the U-GaN layer 10 at a growth temperature of 800°C and a growth pressure of 400mbar,

[0029] The growth thickness is 1nm; the growth temperature of U-AlGaN layer 11 is 800°C, the growth pressure is 400mbar, the growth thickness is 1nm, and the Al composition is 0.2; the growth temperature of U-InGaN layer 12 is 800°C, the growth pressure is 400mbar, and the growth thickness is 1nm, and the In composition is 0.05 .

[0030] ③Secondly, the growth temperature of the N-AlGaN layer 13 is 800°C, and the growth pressure is

[0031] 400mbar, the growth thickness is 1nm, the Al composition is 0.2, and the Si doping concentration is 5×10 17 ; The growth temperature of N-InGaN layer 14 is 800°C, the growth pressure is 400mbar, the growth thickness is 1nm, the In composition is 0.05, and the Si doping concentration is 1×10 18 .

[0032] ④Finally, grow the P-AlGaN layer 15 at a growth temperature of 800°C and a growth pressure of

[0033] 400mbar, the growth thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com