Method for reducing Fischer-Tropsch synthesis iron-based catalyst

An iron-based catalyst, Fischer-Tropsch synthesis technology, applied in the direction of chemical instruments and methods, catalyst activation/preparation, heterogeneous catalyst chemical elements, etc., can solve the problem of low catalyst activity, achieve high catalyst activity, reduce oxidation, The effect of low selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0058] According to a preferred embodiment of the present invention, the preferred reducing conditions further include: a pressure of 2-5 MPa, preferably 2.5-3.5 MPa.

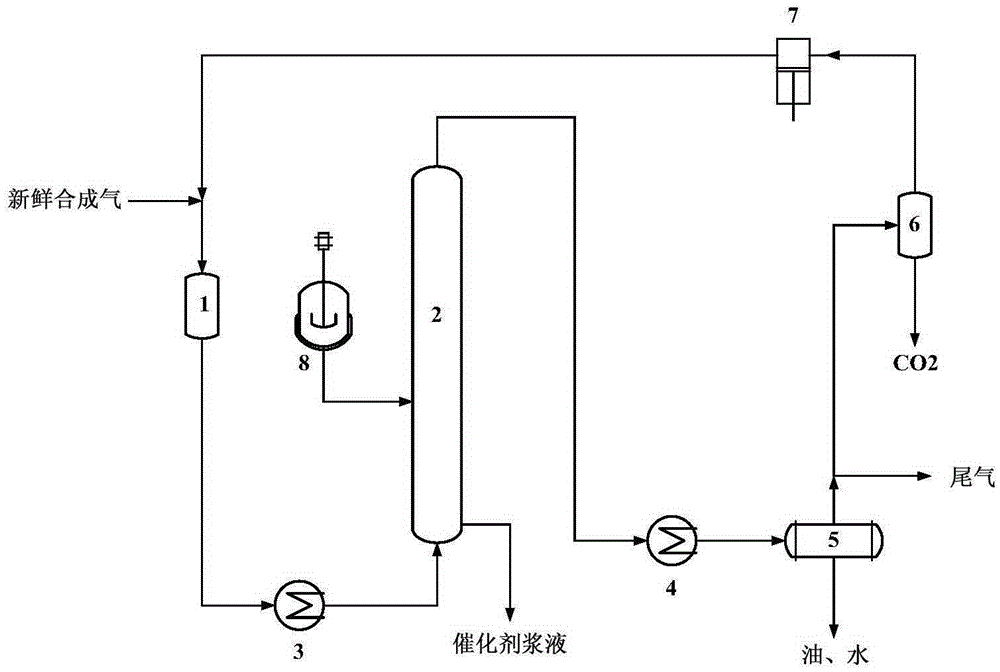

[0059] According to a preferred embodiment of the present invention, such as figure 1 Shown, the present invention carries out as follows:

[0060] The mixed gas mixed with fresh reducing gas (abbreviated as fresh synthesis gas in the figure) and circulating gas is dehydrated in the dehydration tank 1, enters the preheater 3 for preheating, and then enters the reduction reactor from the bottom of the reduction reactor 2; The catalyst slurry obtained by mixing the microspherical Fischer-Tropsch synthesis iron-based catalyst with liquid paraffin (or heavy diesel oil) is added into the reduction reactor from the catalyst slurry tank 8 to be reduced, the reactor is pressurized and heated, and the The gas enters the cooler 4 for condensing and cooling, and then enters the gas-liquid separator 5 for gas-liquid separ...

preparation example

[0068] This preparation example is used to illustrate the preparation of an iron-based catalyst for Fischer-Tropsch synthesis of the present invention.

[0069] Weigh 10.0kg Fe(NO 3 ) 3 9H 2 O, 0.18kg Cu(NO 3 ) 2 ·3H 2 O, add 32L deionized water and stir to dissolve to obtain a mixed solution of iron salt. Weigh 7.0kg Na 2 CO 3, Add 20L of deionized water and stir to dissolve to obtain an alkaline salt solution. Heat the above-mentioned iron salt mixed solution and alkaline salt solution to above 80°C respectively, and then add them into a vigorously stirred reaction tank, control the precipitation temperature in the reaction tank to 80°C, pH value to 7.5, stirring speed at 80rpm, and react for 40 minute. After the precipitation, the precipitated slurry was aged for 1 hour, vacuum filtered, and washed repeatedly with deionized water for 4 times to obtain a filter cake.

[0070] Add 3.5 kg of potassium silicate aqueous solution with a mass concentration of 20% to the ...

Embodiment 1

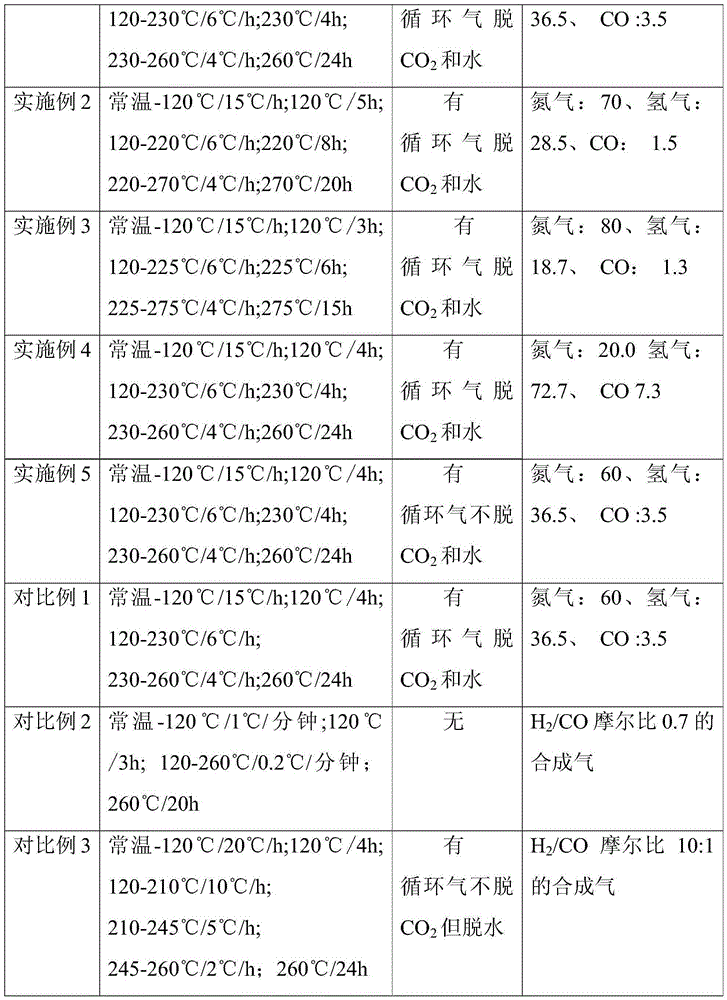

[0072] Add 40g of Catalyst-1 and 800mL of liquid paraffin in a 2L stirred tank reduction reactor, replace the air in the reactor with nitrogen, and continuously feed 60% by volume of nitrogen, 36.5% by volume of hydrogen, and 3.5% by volume of CO into the reactor. Fresh reducing gas, fresh reducing gas space velocity is 4500h -1 , boost the pressure of the reduction reactor to 2.7MPa, start stirring so that the stirring speed is 600rpm, and heat up according to the set program. The specific heating process is as follows:

[0073] The heating conditions of the reduction reactor are as follows: the heating rate of normal temperature -120°C is 15°C / h, 120°C constant temperature 4h; the heating rate of 120-230°C is 6°C / h, 230°C constant temperature 4h; 4°C / h, constant temperature at 260°C for 24h;

[0074] The gas from the top of the reactor is condensed and cooled to separate oil and water, and then part of it is discharged directly as tail gas, and the other part of the gas is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com