A kind of bamboo wood natural anti-mildew preservative

A preservative and wood technology, applied in the direction of wood impregnation, wood impregnation, wood processing appliances, etc., can solve the problems of mildew-proof preservative toxicity, human harm, etc., and achieve the effect of strong anti-loss and long-term mildew-proof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Production method of ginkgo exocarp extract: (1) Drying and pulverization: fresh ginkgo fruit is removed from ginkgo fruit to obtain exocarp, dried in a vacuum drying oven at 65° C. to a moisture content of 4.65%, and pulverized until most of the particles exceed 50 mesh. sieve; (2) leaching: take 70% ethanol solution as the leaching solution, carry out leaching according to the ratio of material to liquid (weight of material / weight of solution) 1:5, and the leaching time is 5 hours; during the leaching process, ultrasonic treatment for 4 (3) Purification: the leaching solution is filtered to obtain a filtrate, add 0.1 mol / L acetic acid to the filtrate, adjust the pH value to 3.0, extract 4 times with ethyl acetate, and separate out ethyl acetate. Ester phase; (4) Concentration: the ethyl acetate phase is rotary-steamed at 75°C to obtain Ginkgo biloba exocarp extract.

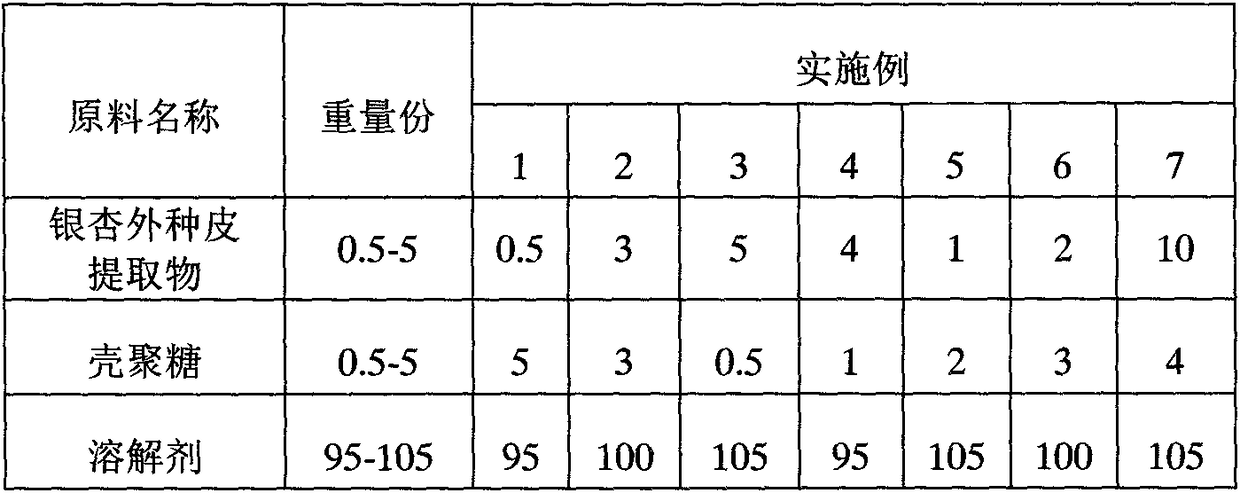

[0019] With reference to the raw materials and the value of parts by weight of Example 1 in the above...

Embodiment 2

[0021] Production method of ginkgo exocarp extract: (1) Drying and pulverization: fresh ginkgo fruit is removed from ginkgo fruit to obtain exocarp, dried in a vacuum drying oven at 65° C. to a moisture content of 4.28%, and pulverized until most of the particles exceed 50 mesh. sieve; (2) leaching: take 50% ethanol solution as the leaching solution, carry out leaching according to the ratio of material to liquid (weight of material / weight of solution) 1:10, and the leaching time is 3 hours; during the leaching process, ultrasonic treatment for 3 (3) Purification: the leaching solution is filtered to obtain a filtrate, add 0.1 mol / L acetic acid to the filtrate, adjust the pH value to 3.5, extract 3 times with ethyl acetate, and separate to obtain ethyl acetate Ester phase; (4) Concentration: the ethyl acetate phase was rotary-steamed at 70° C. to obtain the Ginkgo biloba seed coat extract.

[0022] With reference to the raw material and the parts by weight value of Example 2 i...

Embodiment 3

[0024] Production method of Ginkgo biloba seed coat extract: (1) with embodiment 1; (2) leaching: take 30% ethanol solution as leaching solution, carry out leaching according to the ratio of material to liquid (weight of material / weight of solution) 1:5 , the leaching time is 2 hours; during the leaching process, ultrasonic treatment is performed twice for 15 minutes each time; (3) Purification: the leaching solution is filtered to obtain a filtrate, and 0.1mol / L acetic acid is added to the filtrate to adjust the pH value To 3, extracted twice with ethyl acetate to separate the ethyl acetate phase; (4) Concentration: the ethyl acetate phase was subjected to rotary evaporation at 70°C to obtain the Ginkgo biloba seed coat extract.

[0025] With reference to the raw materials and the parts by weight value of Example 3 in the above table, 5 parts of Ginkgo biloba exocarp extracts were first added to 105 parts of dissolving agents (the ratio of ethanol to water 5:5), and 0.5 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com