Hydrogen peroxide-ozone-ultraviolet joint treatment method for unsymmetrical dimethylhydrazine sewage

A technology of hydrogen peroxide and unsymmetrical dimethylhydrazine, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, multi-stage water treatment, etc., can solve the problems of low oxidation efficiency, high oxidation cost, and undiscovered problems, and achieve degradation High efficiency, faster response speed, and improved response reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

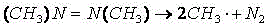

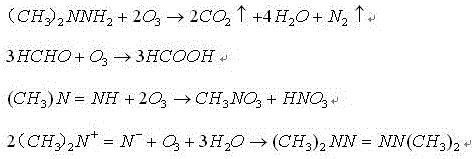

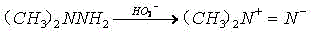

Method used

Image

Examples

Embodiment 1

[0043] Take the unsymmetrical dimethylhydrazine sewage with a treatment concentration of 1% and a treatment volume of 18L as an example.

[0044] The oxygen cylinder is filled with industrial oxygen, the pressure P≤15MPa, and the oxygen is oxygen with a purity greater than 99.9%.

[0045] The ozone generator is a high-voltage discharge ozone generator commonly used in the field, and the output of the oxygen source is 20g / h.

[0046] Steps:

[0047] (1) Filling with sewage: Fill the stainless steel reactor with sewage from the sewage inlet.

[0048] (2) Add hydrogen peroxide: add hydrogen peroxide from the sewage inlet to the stainless steel reactor, the ratio of hydrogen peroxide to unsymmetrical dimethylhydrazine is 6:1, adjust the pH to 9.3, and open the oxygen cylinder , Oxygen is blown into the reactor through the oxygen line.

[0049] (3) Turn on the ultraviolet lamp, which is a combination of a vacuum ultraviolet (VUV) lamp with a power of 120W (wavelength 185nm) and ...

Embodiment 2

[0054] Take the unsymmetrical dimethylhydrazine sewage with a treatment concentration of 1% and a treatment volume of 18L as an example.

[0055] The oxygen cylinder is filled with industrial oxygen, the pressure P≤15MPa, and the oxygen is oxygen with a purity greater than 99.9%.

[0056] The ozone generator is a high-voltage discharge ozone generator commonly used in the field, and the output of the oxygen source is 20g / h.

[0057] Steps:

[0058] (1) Filling with sewage: Fill the stainless steel reactor with sewage from the sewage inlet.

[0059] (2) Add hydrogen peroxide: add hydrogen peroxide to the stainless steel reactor from the sewage inlet, the ratio of hydrogen peroxide to unsymmetrical dimethylhydrazine is 4:1, adjust the pH to 8.7, and open the oxygen cylinder , Oxygen is blown into the reactor through the oxygen line.

[0060] (3) Turn on the ultraviolet lamp, which is a combination of a vacuum ultraviolet (VUV) lamp with a power of 120W (wavelength 185nm) and ...

Embodiment 3

[0065] Take the unsymmetrical dimethylhydrazine sewage with a treatment concentration of 1% and a treatment volume of 18L as an example.

[0066] The oxygen cylinder is filled with industrial oxygen, the pressure P≤15MPa, and the oxygen is oxygen with a purity greater than 99.9%.

[0067] The ozone generator is a high-voltage discharge ozone generator commonly used in the field, and the output of the oxygen source is 20g / h.

[0068] Steps:

[0069] (1) Filling with sewage: Fill the stainless steel reactor with sewage from the sewage inlet.

[0070] (2) Add hydrogen peroxide: add hydrogen peroxide to the stainless steel reactor from the sewage inlet, the ratio of hydrogen peroxide to unsymmetrical dimethylhydrazine is 5:1, adjust the pH to 9.0, and open the oxygen cylinder , Oxygen is blown into the reactor through the oxygen line.

[0071] (3) Turn on the ultraviolet lamp, which is a combination of a vacuum ultraviolet (VUV) lamp with a power of 120W (wavelength 185nm) and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com