Preparation method for snowflake-shaped ZnO/BiOI composite material

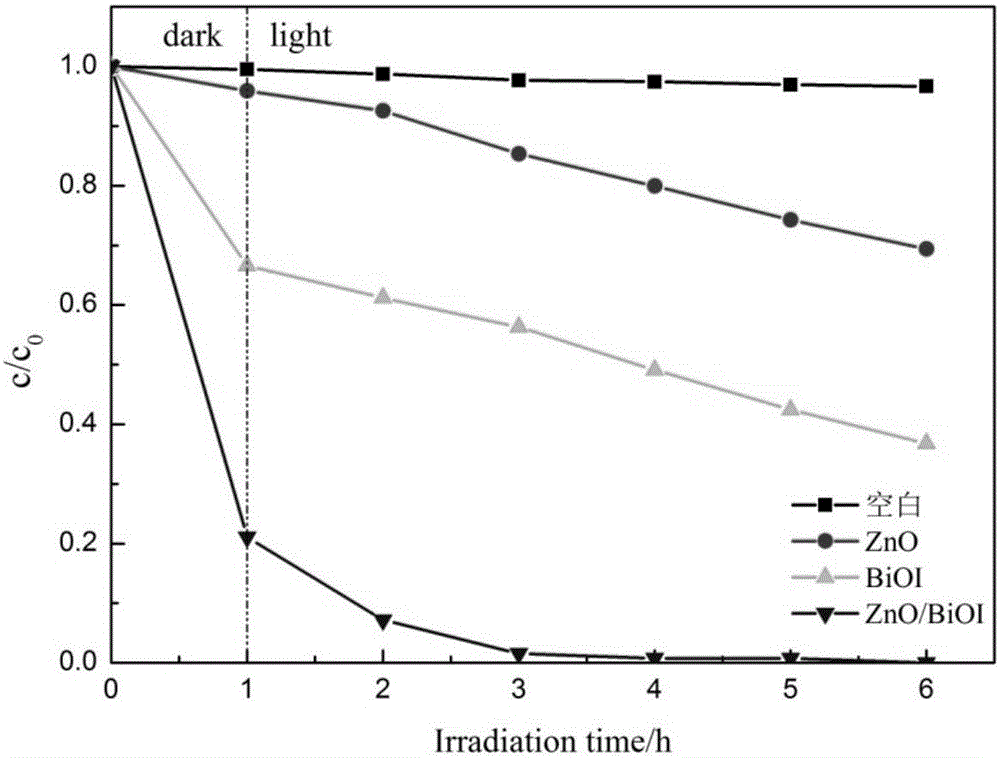

A composite material and snowflake-like technology, which is applied in the field of preparation of snowflake-like ZnO/BiOI composite materials, can solve problems such as the preparation method of snowflake-like ZnO/BiOI composite materials, etc., to promote visible light photocatalytic activity and improve adsorption properties. , the effect of response time control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

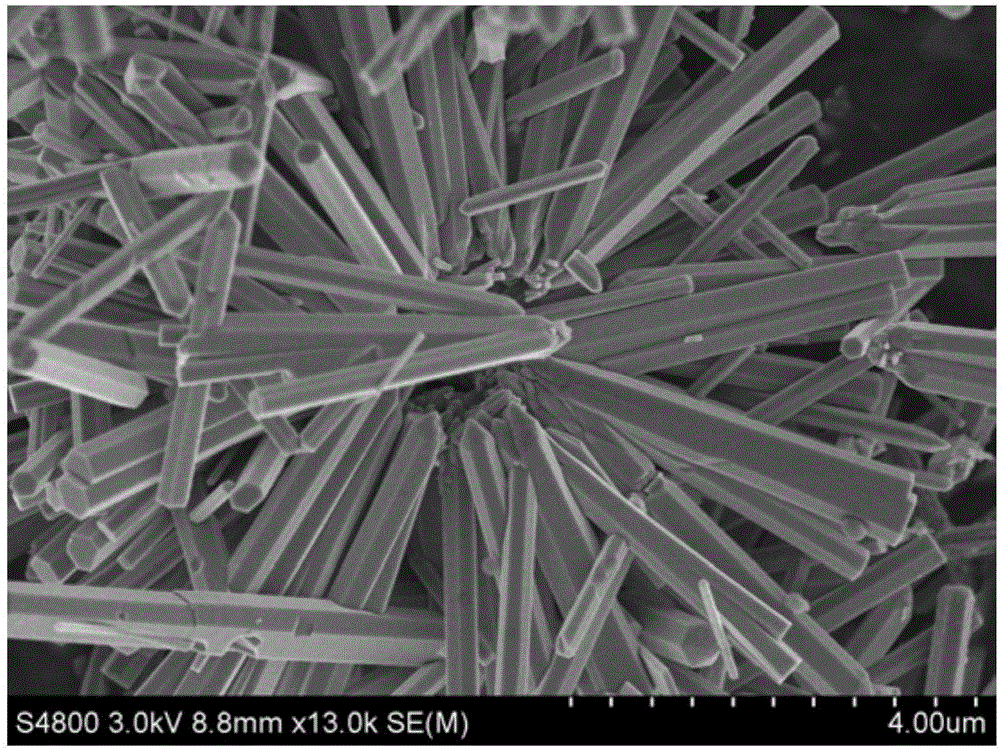

[0023] 1) Add 0.5g Zn(NO 3 ) 3 ·6H 2 O and 1.5g NaOH were dissolved in 3mL of deionized water, and then 1g of sodium dodecyl sulfate (SDS) was dispersed in a mixed solution of 100mL of deionized water and 25mL of absolute ethanol, and then the above two solutions were mixed and magnetically stirred After 30 minutes, move it into a polytetrafluoroethylene tank, place it in an MDS-10 microwave digestion apparatus, and obtain a white precipitate after a hydrothermal reaction at 180°C for 40 minutes, wash it with absolute ethanol and deionized water alternately for 3 times, and filter it. After drying, the flower-shaped ZnO nanorods are obtained.

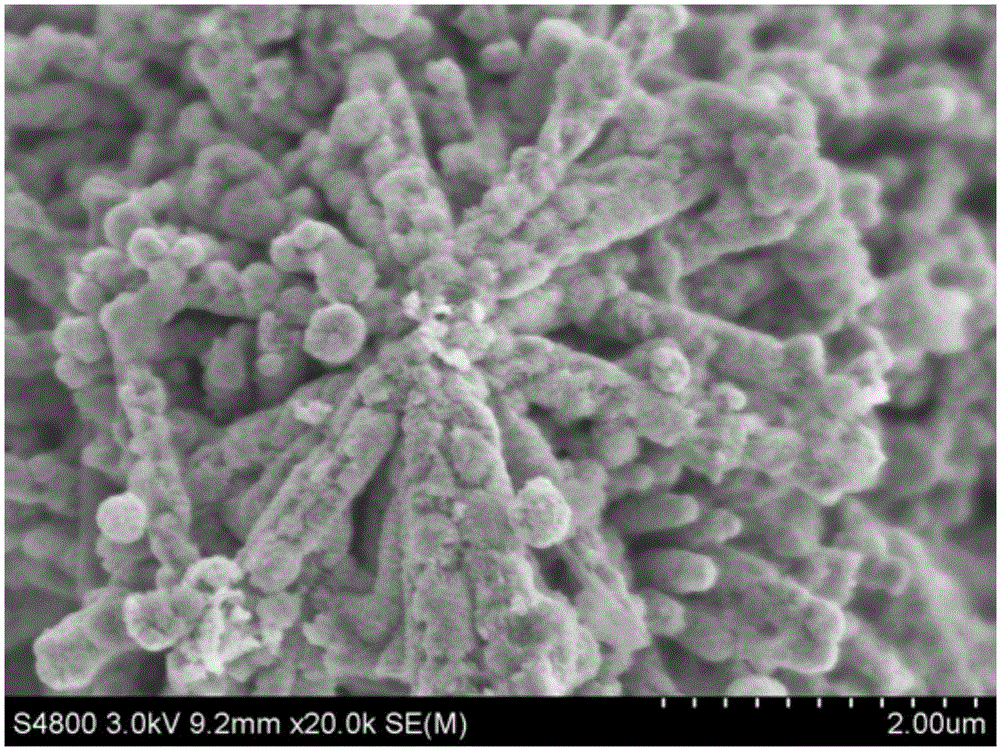

[0024] 2) Mix 0.2g KI and 0.6g Bi(NO 3 ) 3 ·5H 2 O was added to 40mL of ethylene glycol, stirred by magnetic force for 40min, and then 0.2g of the flower-like ZnO nanorods obtained in step 1) was added, ultrasonically dispersed for 20min, poured into an autoclave, solvothermally reacted at 160°C for 3h, and dissolved in absolute et...

Embodiment 2

[0026] 1) Add 0.7g Zn(NO 3 ) 3 ·6H 2 O and 2.5g NaOH were dissolved in 4mL deionized water, and then 1.7g sodium dodecyl sulfate (SDS) was dispersed in a mixed solution of 100mL deionized water and 30mL absolute ethanol, and then the above two solutions were mixed and magnetically After stirring for 30 minutes, move it into a polytetrafluoroethylene tank, place it in a MDS-10 microwave digestion apparatus, and obtain a white precipitate after a hydrothermal reaction at 170°C for 35 minutes, wash it by alternating centrifugation with absolute ethanol and deionized water for 3 times, and filter , and dried to obtain flower-like ZnO nanorods.

[0027] 2) Mix 0.1g KI and 0.38g Bi(NO 3 ) 3 ·5H 2 O was added to 30mL of ethylene glycol, stirred magnetically for 50min, then added 0.2g of the flower-shaped ZnO nanorods obtained in step 1), dispersed ultrasonically for 15min, poured into an autoclave, and reacted solvothermally at 130°C for 2h. Alternately centrifuged with deioniz...

Embodiment 3

[0029] 1) 0.3g Zn(NO 3 ) 3 ·6H 2 O and 1.0g NaOH were dissolved in 5mL of deionized water, and then 2g of sodium dodecyl sulfate (SDS) was dispersed in a mixed solution of 150mL of deionized water and 30mL of absolute ethanol, and then the above two solutions were mixed and magnetically stirred After 30 minutes, move it into a polytetrafluoroethylene tank, place it in a MDS-10 microwave digestion apparatus, and obtain a white precipitate after a hydrothermal reaction at 150°C for 35 minutes, and wash it with absolute ethanol and deionized water alternately for 3 times, and filter it. After drying, the flower-shaped ZnO nanorods are obtained.

[0030] 2) Mix 0.15g KI and 0.5g Bi(NO 3 ) 3 ·5H 2 O was added to 20 mL of ethylene glycol, stirred by magnetic force for 40 min, then 0.25 g of the flower-shaped ZnO nanorods obtained in step 1) were added, ultrasonically dispersed for 25 min, poured into an autoclave, solvothermally reacted at 150°C for 3 h, and dissolved in absolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com