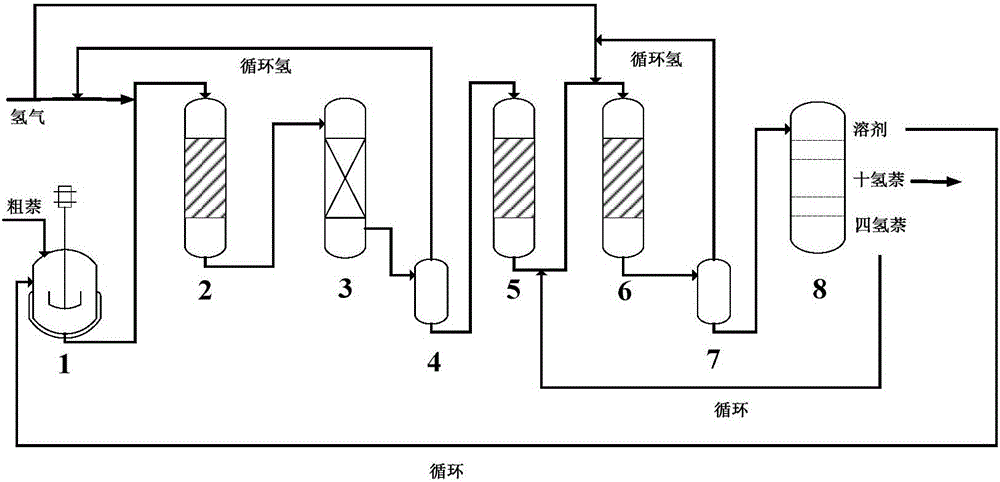

Method for producing decalin through crude naphthalene hydrodesulfurization

A technology for hydrodesulfurization and decalin, which is applied in chemical instruments and methods, hydrogenation to hydrocarbons, hydrocarbons, etc., can solve the problems of short service life of catalysts, increased production costs, and high content of precious metals in hydrogenation catalysts, and can prolong the life of the catalyst. Service life, low operating pressure, elimination of activity inhibition and poisoning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Using cyclohexane as a solvent, the raw materials are configured according to the mass ratio of industrial naphthalene:cyclohexane=10:90.

[0035] The loading capacity of the first-stage hydrogenation catalyst is 100ml, the catalyst is a Ni-Mo catalyst, and the carrier is Al 2 o 3 , based on the weight of the catalyst, where the content of NiO is 8%, MO 3 The content is 16%. The catalyst needs to be pre-sulfided in the reactor before use, using carbon disulfide / cyclohexane with a volume content of 2% as the vulcanizing agent, and the vulcanized liquid space velocity is 1h -1 , the gas-liquid volume ratio is 600:1. After the catalyst is vulcanized at 240°C for 24 hours, continue to vulcanize at 300°C for 6 hours, use lead acetate to check whether the vulcanization is complete, and stop the vulcanization after the vulcanization is complete. The first hydrogenation reaction temperature is 280°C, the reaction pressure is 4MPa, and the liquid space velocity is 1h -1 , T...

Embodiment 2

[0040] This implementation operates according to Example 1, but there are the following differences:

[0041] Using cyclohexane as a solvent, configure raw materials according to the mass ratio of industrial naphthalene: cyclohexane=10:90;

[0042] The first-stage hydrogenation catalyst component and loading are the same as those in Example 1, and it needs to be pre-sulfurized in the reactor before use, using dimethyl disulfide / cyclohexane with a volume content of 2% as the vulcanizing agent, and the vulcanized liquid space velocity for 1h -1 , the gas-liquid volume ratio is 600:1; after the catalyst is vulcanized at 240°C for 24 hours, continue to vulcanize at 300°C for 6 hours, use lead acetate to detect whether the vulcanization is complete, and stop vulcanization after the vulcanization is complete. The first hydrogenation reaction temperature is 300°C, the reaction pressure is 4MPa, and the liquid space velocity is 2h -1 , the gas-liquid volume ratio is 600:1;

[0043]...

Embodiment 3

[0047] This implementation operates according to Example 1, but there are the following differences:

[0048] With n-heptane as solvent, configure raw materials according to mass ratio industrial naphthalene: n-heptane=10:90;

[0049] The one-stage hydrogenation catalyst component and loading are the same as in Example 1, and it needs to be pre-sulfurized in the reactor before use, using dimethyl disulfide / cyclohexane with a volume content of 2% as the vulcanizing agent, and the vulcanized liquid space velocity for 1h -1 , the gas-liquid volume ratio is 600:1. After the catalyst is vulcanized at 240°C for 48 hours, use lead acetate to detect whether the vulcanization is complete, and stop the vulcanization after the vulcanization is complete. The first hydrogenation reaction temperature is 300°C, the reaction pressure is 6MPa, and the liquid space velocity is 2.5h -1 , the gas-liquid volume ratio is 400:1;

[0050] The washing tower uses sodium carbonate solution, the oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com