Sodium alginate degradation method

A sodium alginate and acid solution technology, which is applied in the field of polysaccharide degradation, can solve the problems of high degradation cost and difficult separation of degradation products, and achieve the effects of simple preparation technology, convenient product separation, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

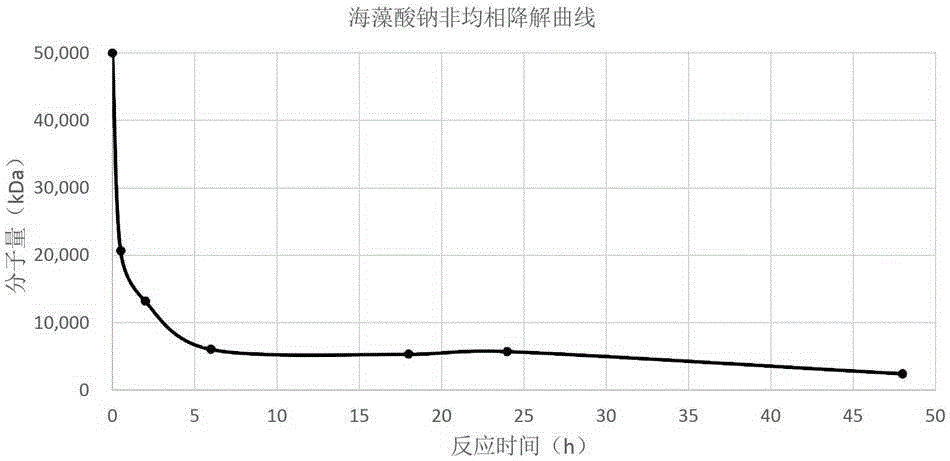

[0017] Disperse 1 part (g) of sodium alginate with an initial viscosity-average molecular weight of 50,075,000 Daltons in 40 parts (ml) of a 13 mol / L ethanol solution, and add 20 parts ( ml), reflux reaction at 50°C for 48 hours, filter the reaction system, wash the filter residue with deionized water and 75% ethanol solution until neutral, disperse in 75% ethanol solution, add sodium hydroxide solution dropwise, adjust the pH of the system to greater than or equal to 7, the obtained sodium alginate suspension was suction-filtered, and the filter residue was washed with 75% ethanol until neutral, then washed with graded alcohol (75%, 95%, absolute ethanol) and dehydrated. Dry under vacuum at 60°C. The degraded sodium alginate was measured by Ubbelohde's viscosity method, and the viscosity-average molecular weight was 2,068,400 Daltons.

Embodiment 2

[0019] Disperse 1 part (g) of sodium alginate with an initial viscosity-average molecular weight of 59,095,000 Daltons in 45 parts (ml) of a 24 mol / L methanol solution, and add 15 parts ( ml), reflux at 80°C for 24 hours, filter the reaction system, wash the filter residue with deionized water and 75% ethanol solution to neutrality, disperse in 75% ethanol solution, add sodium hydroxide solution dropwise, adjust the pH of the system to greater than or equal to 7, the obtained sodium alginate suspension was suction-filtered, and the filter residue was washed with 75% ethanol until neutral, then washed with graded alcohol (75%, 95%, absolute ethanol) and dehydrated. Dry under vacuum at 60°C. The degraded sodium alginate was measured by Ubbelohde's viscosity method, and the viscosity-average molecular weight was 10,172,200 Daltons.

Embodiment 3

[0021] Disperse 1 part (g) of sodium alginate with an initial viscosity-average molecular weight of 38,690,500 Daltons in 50 parts (ml) of 5 mol / L n-propanol solution, and add acetic acid solution with a molar concentration of 17 mol / L under stirring for 10 Parts (ml), reflux at 70°C for 0.5 hours, filter the reaction system, wash the filter residue with deionized water and 75% ethanol solution to neutrality, disperse in 75% ethanol solution, add sodium hydroxide solution dropwise, mediate When the pH of the system is greater than or equal to 7, the obtained sodium alginate suspension is suction-filtered, and the filter residue is washed with 75% ethanol until neutral, then washed with gradient alcohol (75%, 95%, absolute ethanol) and dehydrated. Dry under vacuum at 60°C. The degraded sodium alginate was measured by Ubbelohde's viscosity method, and the viscosity-average molecular weight was 11,633,500 Daltons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity average molecular weight | aaaaa | aaaaa |

| viscosity average molecular weight | aaaaa | aaaaa |

| viscosity average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com