Purification method for sugammadex sodium

A technique of sugammadex sodium and a purification method, which is applied in the field of purification, can solve problems such as inconvenient operation, dissociation, and destruction of impurities, and achieve good removal effect, good economy, and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

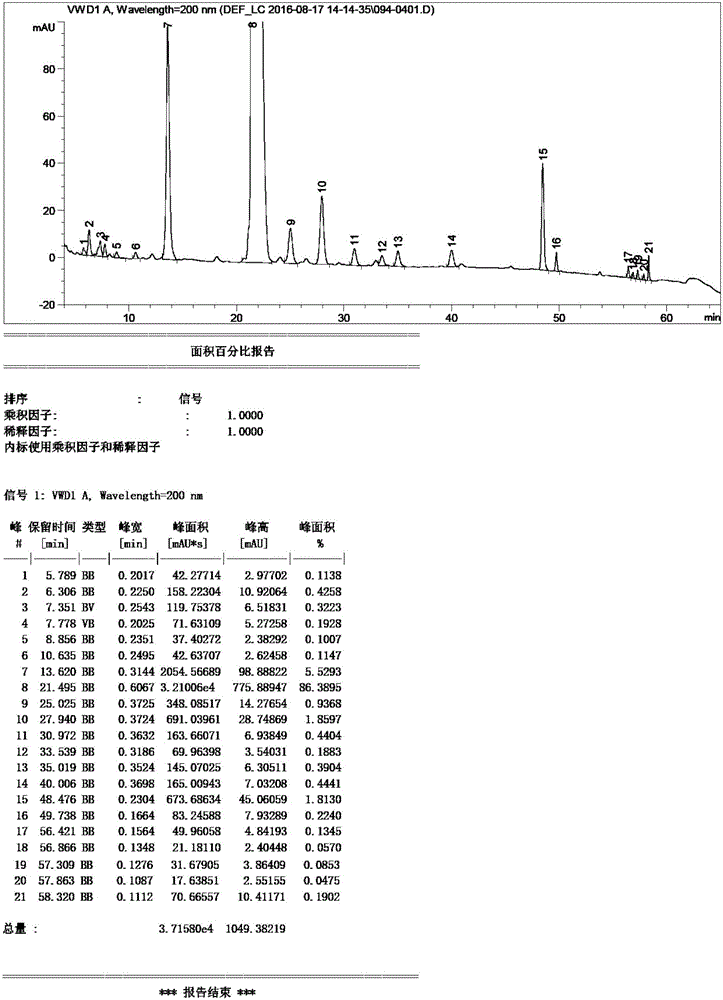

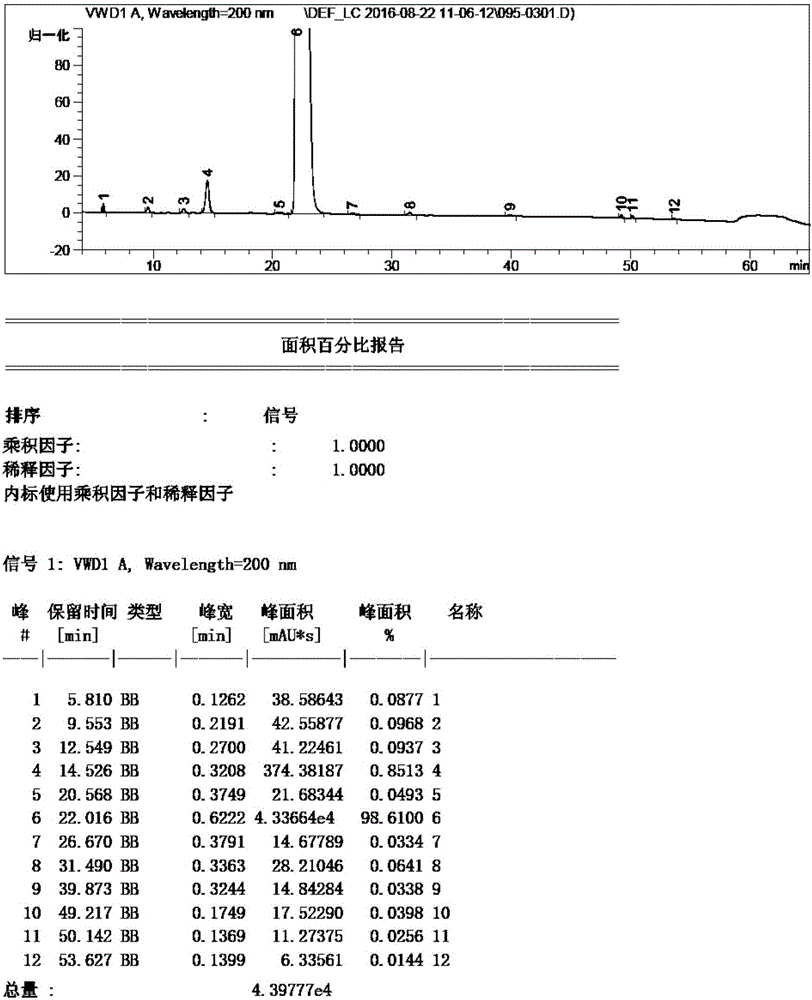

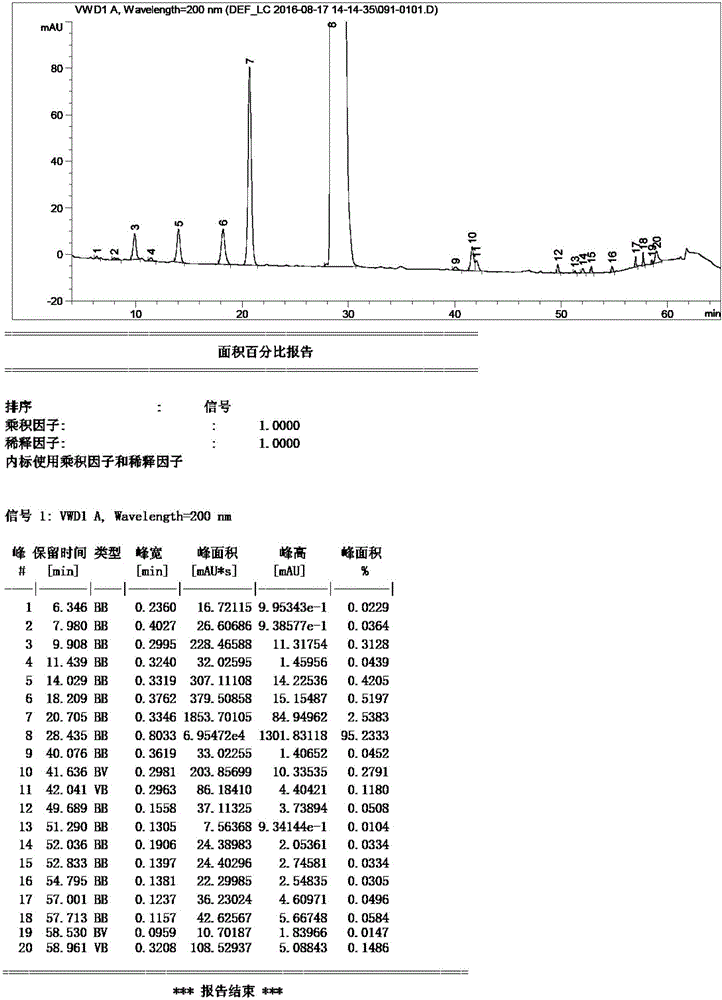

Image

Examples

Embodiment 1

[0035] Embodiment 1: Transformation of ion resin

[0036] 1) Take 1L of D001 strong acidic cation exchange resin, put it into a sand core plate chromatography column, wash the resin with 0.5mol / L NaOH solution for 4 column volumes, the flow rate is 5ml / min, and then wash it with 0.5mol / L NaOH solution Rinse the resin with HCl solution for 4 column volumes at a flow rate of 5 ml / min. After washing, wash with purified water until neutral.

[0037] 2) Take 0.5L of D001 strongly acidic cation exchange resin treated in step 1, add calcium hydroxide suspension (80g dispersed in 1L of water), stir for 2 hours, rinse the resin with purified water until it is clear, set it aside for use, and mark To transform into ion resin A; get the remaining 0.5L D001 strongly acidic cation exchange resin treated in step 1, add an aqueous solution of sodium hydroxide (60g dissolved in 1L water), stir for 2 hours, and rinse the resin to neutral with purified water , placed for use, marked as transit...

Embodiment 2

[0038] Embodiment 2: Purification of sugammadex sodium

[0039]Take 40 g of sugammadex sodium crude product, dissolve it with 3 L of water until it is clear, add about 0.5 L of transionic resin A under stirring, stir at room temperature for 2 hours, a large amount of white solid precipitates, filter with suction, and rinse the filter cake with purified water to obtain a white Solid (sugammadex calcium) 89 grams, add sugammadex calcium into a 500mL three-necked bottle, add 300g of purified water, under nitrogen protection, heat to 80°C and stir for 2 hours, cool down to room temperature, and suction filter to obtain white Solid (purified sugammadex calcium) 32g.

[0040] Put 32g of purified sugammadex calcium into a 3L three-necked bottle, add a mixed solvent of 1L of purified water and 1L of ethanol to the three-necked bottle, add about 0.3L of transition ion resin B, stir for 2 hours, and filter with suction. Add 0.2L of inversion ion resin B, stir for 2 hours, filter with s...

Embodiment 3

[0044] Embodiment 3: Transformation of ion resin

[0045] 1) Take 1L of 732 strong acidic cation exchange resin, put it into a sand core plate chromatography column, wash the resin with 0.5mol / L NaOH solution for 4 column volumes, the flow rate is 5ml / min, and then wash it with 0.5mol / L HCl The solution washes the resin for 4 column volumes, and the flow rate is 5ml / min. After washing, wash with purified water until neutral.

[0046] 2) Take 0.5L of the 732 strongly acidic cation exchange resin treated in step 1), add magnesium hydroxide suspension (80g dispersed in 1L of water), stir for 2 hours, rinse the resin with purified water until it is clear, and set aside for use. Mark it as transition ion resin A; take the remaining 0.5 L of 732 strongly acidic cation exchange resin treated in step 1) and put it aside for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com