Carbon nano-tube/heat conduction silicone grease composite material and preparation method thereof

A carbon nanotube and thermally conductive silicone grease technology, which is applied in the field of carbon nanotube/thermally conductive silicone grease composite materials and their preparation, can solve problems such as rare research on thermally conductive silicone grease, etc. good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

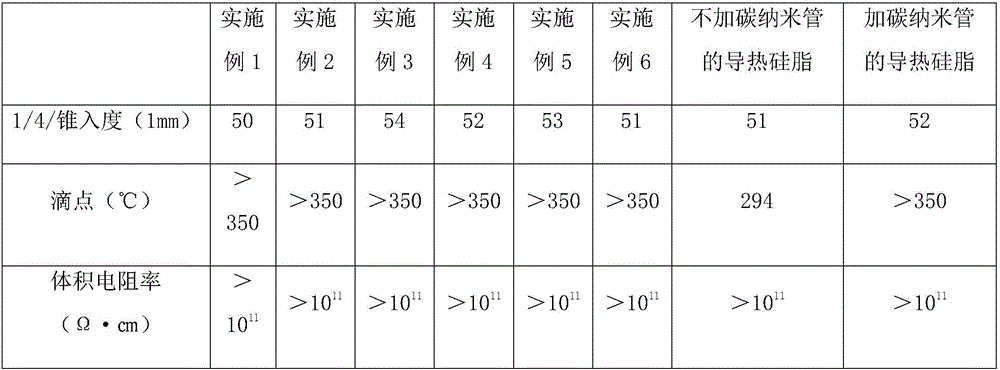

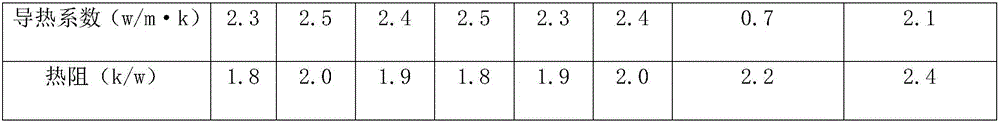

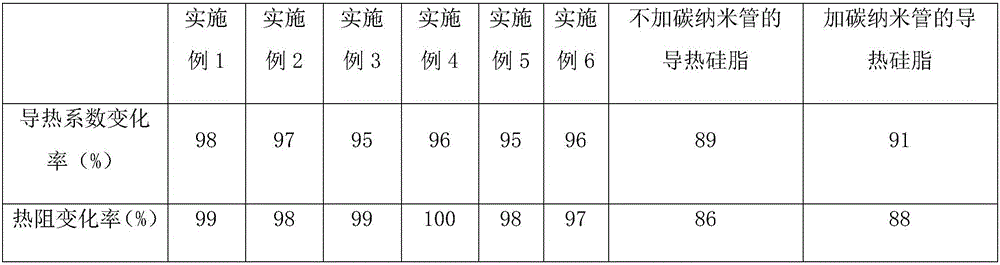

Examples

Embodiment 1

[0030] A carbon nanotube / thermally conductive silicone grease composite material, the mass ratio of carbon nanotubes and thermally conductive silicone grease is 0.01:1, the amount of each component in the thermally conductive silicone grease, in percentage terms, includes methyl silicone oil 14wt%, nitrided 56wt% of aluminum, 23wt% of silicon carbide, 7wt% of nano silver wire and 20wt% of dispersant.

[0031] The specific preparation method is:

[0032] (1) The multi-walled carbon nanotubes with a tube diameter of 10nm and a tube length of 0.5μm are pulverized and loosened by ball milling and high-speed jet milling to obtain pretreated multi-walled carbon nanotubes, and then the material-liquid ratio is 1g:60ml , put the multi-walled carbon nanotubes in a mixed solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 2:1, ultrasonically treat for 30 minutes, condense and reflux for 4 hours, take it out, wash until neutral, and vacuum dry at 10...

Embodiment 2

[0036]A carbon nanotube / thermally conductive silicone grease composite material, the mass ratio of carbon nanotubes and thermally conductive silicone grease is 0.1:1, and the consumption of each component in the thermally conductive silicone grease, by percentage, includes methyl silicone oil 14wt%, nitrided 50wt% of aluminum, 30wt% of silicon carbide, 6wt% of nano silver wire and 22wt% of dispersant.

[0037] The specific preparation method is:

[0038] (1) The multi-walled carbon nanotubes with a tube diameter of 50nm and a tube length of 100μm are pulverized and loosened by ball milling and high-speed jet milling to obtain pretreated multi-walled carbon nanotubes, and then the material-liquid ratio is 1g:80ml, The multi-walled carbon nanotubes were placed in a mixed solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1, ultrasonically treated for 30 minutes, condensed and refluxed for 4 hours, taken out, washed until neutral, and vac...

Embodiment 3

[0042] A carbon nanotube / thermally conductive silicone grease composite material, the mass ratio of carbon nanotubes and thermally conductive silicone grease is 0.05:1, and the consumption of each component in the thermally conductive silicone grease, by percentage, includes methyl silicone oil 14wt%, nitrided 40wt% aluminum, 38wt% silicon carbide, 8wt% silver nano wire and 24wt% dispersant.

[0043] The specific preparation method is:

[0044] (1) The multi-walled carbon nanotubes with a tube diameter of 20nm and a tube length of 10μm are pulverized and loosened by ball milling and high-speed jet mill to obtain pretreated multi-walled carbon nanotubes, and then the material-liquid ratio is 1g:70ml, The multi-walled carbon nanotubes were placed in a mixed solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 2.5:1, ultrasonically treated for 30 minutes, condensed and refluxed for 4 hours, taken out, washed until neutral, and vacuum-dried at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com