Red-light carbon dot of high yield and high quantum yield, and preparation method thereof

A quantum yield and high yield technology, applied in the field of nanomaterials, can solve the problems of low quantum yield, weak absorption and emission, and low separation efficiency, and achieve good luminous efficiency, extreme luminous efficiency, and high luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

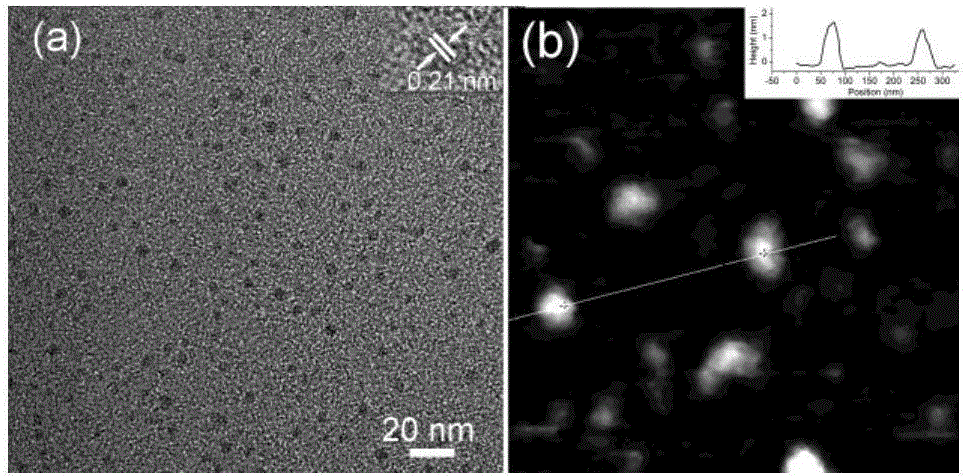

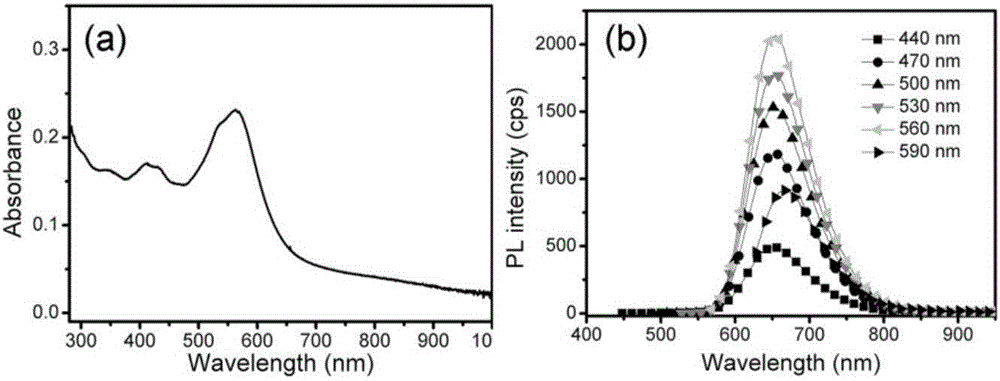

Image

Examples

preparation example Construction

[0026] The solvent used in the preparation process of the red light carbon quantum dots of the present invention is dimethyl sulfoxide instead of other commonly used solvents such as water and ethanol. Dimethyl sulfoxide solvent can prepare red carbon dots, but water and ethanol cannot, and it is selected to help precipitate and separate samples. The preparation method specifically comprises the following specific steps:

[0027] (1) Preparation of red fluorescent carbon quantum dot mixture by solvothermal method:

[0028] First measure 5-15ml of formamide into a 50ml centrifuge tube, then weigh a certain amount of citric acid (0.2-0.6g) and a certain amount of ethylenediamine (100-1300μL) into the centrifuge tube, Shake until completely dissolved, transfer the mixture to a high-pressure reactor containing 80mL dimethyl sulfoxide, and seal it for storage; first preheat the high-temperature oven to a certain temperature (160-220 degrees Celsius), and then put the reactor into ...

Embodiment 1

[0034] (1) Prepare a mixed solution containing red fluorescent carbon dots

[0035] First put 0.4g of citric acid into a 100mL conical flask, then add 10mL of formamide solvent, and form a transparent solution by shaking; then, add 0.7mL of ethylenediamine, and shake further to make the sample evenly dispersed. Then, the transparent mixed solution was transferred to a stainless steel reaction kettle (150 ml) containing 80 mL of dimethyl sulfoxide, and sealed for preservation. First preheat the high-temperature oven to 190 degrees Celsius (heating rate: 5 degrees Celsius / minute), then put the stainless steel reactor into the oven for 6 hours of reaction, after the reaction is completed, turn off the oven, open the oven door, and cool down to room temperature naturally.

[0036] (2) Purify the mixed solution containing red fluorescent carbon dots

[0037] The mixed solution obtained after the reaction in step (1) is first filtered to remove unreacted impurities and large partic...

Embodiment 2

[0043] The preparation method is the same as in Example 1, but the reaction temperature is changed to 220° C., and other conditions remain unchanged, and the emission wavelength of the finally obtained red fluorescent carbon dots is 661 nm. Compared with the emission wavelength at 190 °C, the red shift is 7 nm, which is attributed to the higher degree of graphitization caused by the higher reaction temperature. At the same time, the quantum yield after the integrating sphere measurement dropped to 45%. In addition, the mass yield, that is, the yield of the sample, also increased, reaching 84%. From the results, increasing the reaction temperature will produce a slight emission red shift and an increase in the mass yield, while reducing the quantum yield.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com