Anode composite material, and preparation method thereof

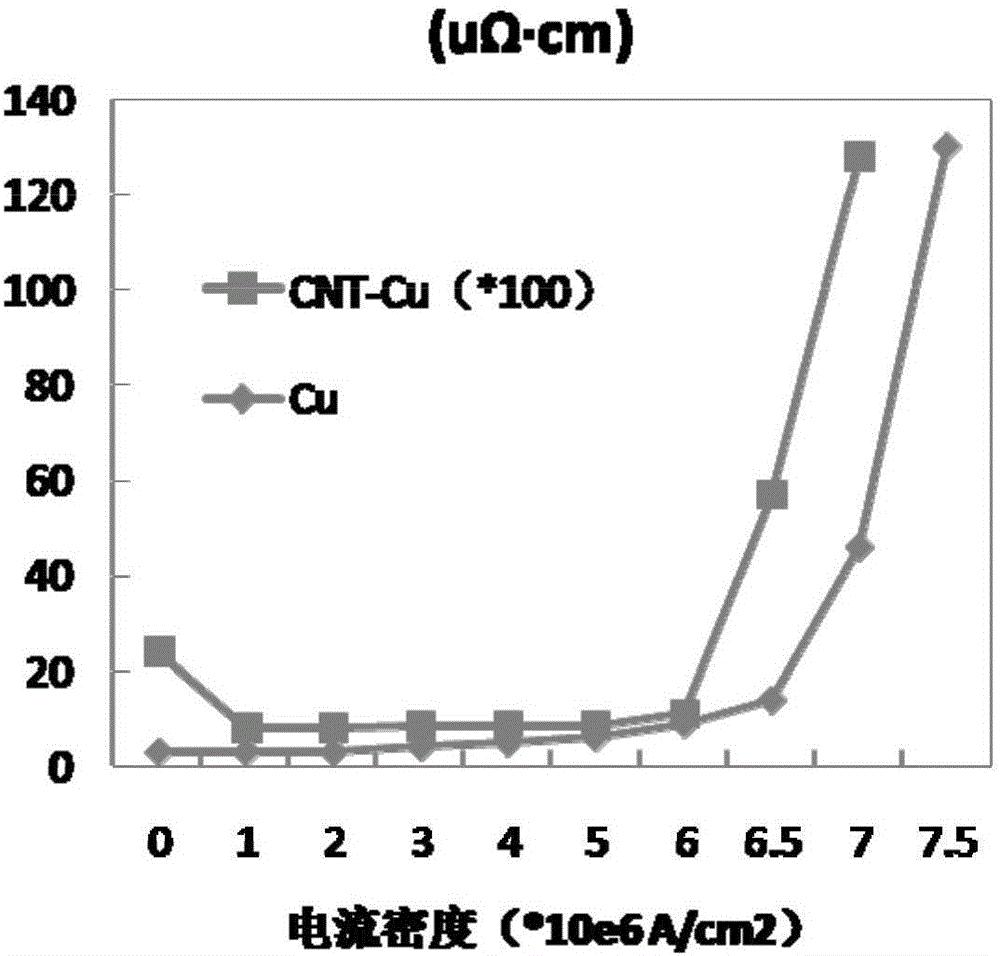

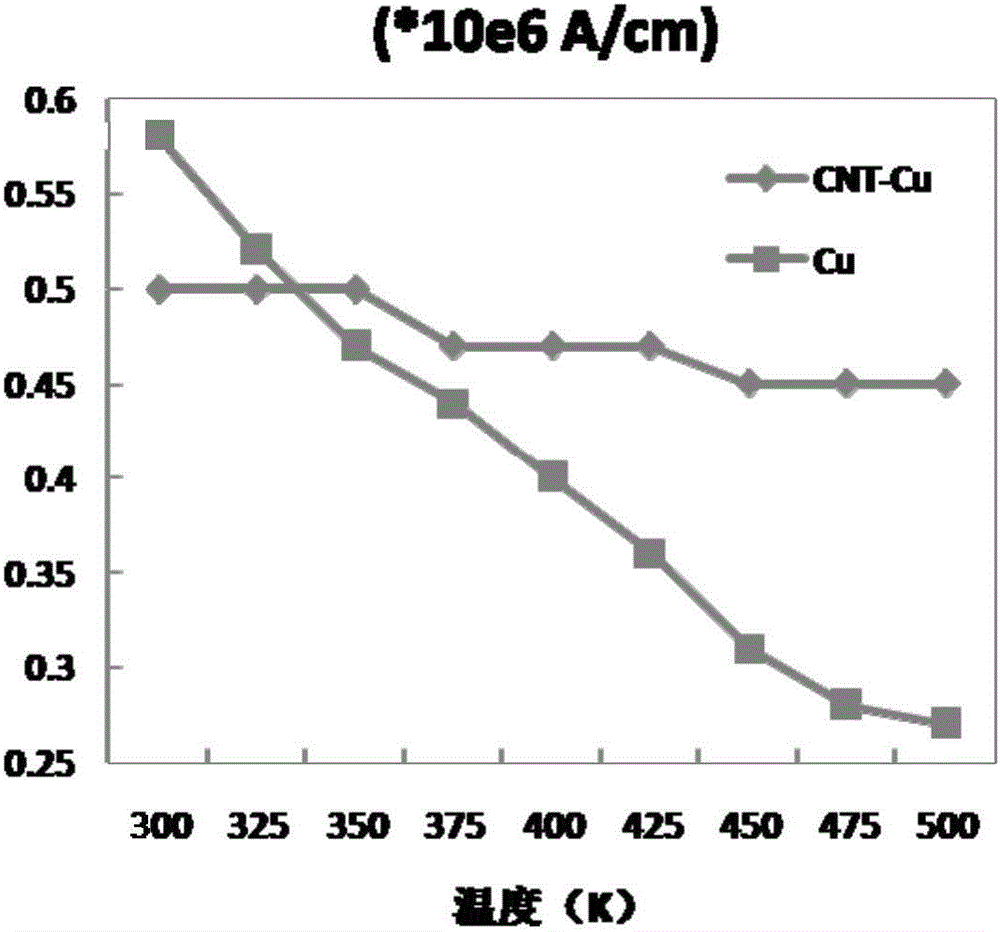

A composite material and anode technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of large irreversible capacity loss and failure to become a high-energy density battery, so as to avoid large-sized dendrites, improve ion conductivity, and strong The effect of absorbency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Prepare 800g of copper powder as a raw material, with a particle size of less than 500nm; 200g of carbon nanotube dry powder, with a diameter of 20-120nm and a length of 2-20μm. Copper powder and carbon nanotube dry powder were uniformly mixed under vacuum conditions, pressed at 250 MPa at 200° C., and kept under pressure for 1 hour. Then it was moved to a tube furnace, and under the protection of hydrogen, it was first raised to 350°C at a rate of 4°C / min, kept for 4 hours, then rapidly raised to 900°C at 18°C / min, kept for 1 hour, and then cooled naturally with the furnace. That is, the C-Cu composite material in which carbon nanotubes are uniformly dispersed in the copper matrix is obtained, and rolled to a thickness of about 0.9mm under the protection of high-temperature inert gas (argon), that is, a C-Cu composite current collector is obtained, in which the carbon nanotubes The tube content is 50 vol.%.

Embodiment 2

[0031]Prepare 800g of copper powder as a raw material, with a particle size of less than 500nm; 200g of carbon nanotube dry powder, with a diameter of 20-120nm and a length of 2-20μm. Copper powder and carbon nanotube dry powder were uniformly mixed under vacuum conditions, pressed at 200° C. at 250 MPa and held for 1 hour. Then it was moved to a tube furnace, and under the protection of hydrogen, it was first raised to 350°C at a rate of 4°C / min, kept for 4 hours, then rapidly raised to 900°C at 18°C / min, kept for 1 hour, and then cooled naturally with the furnace. That is, the C-Cu composite material in which carbon nanotubes are uniformly dispersed in the copper matrix is obtained, and rolled to a thickness of about 0.9mm under the protection of high-temperature inert gas (argon), that is, a C-Cu composite current collector is obtained, in which the carbon nanotubes The tube content is 50 vol.%.

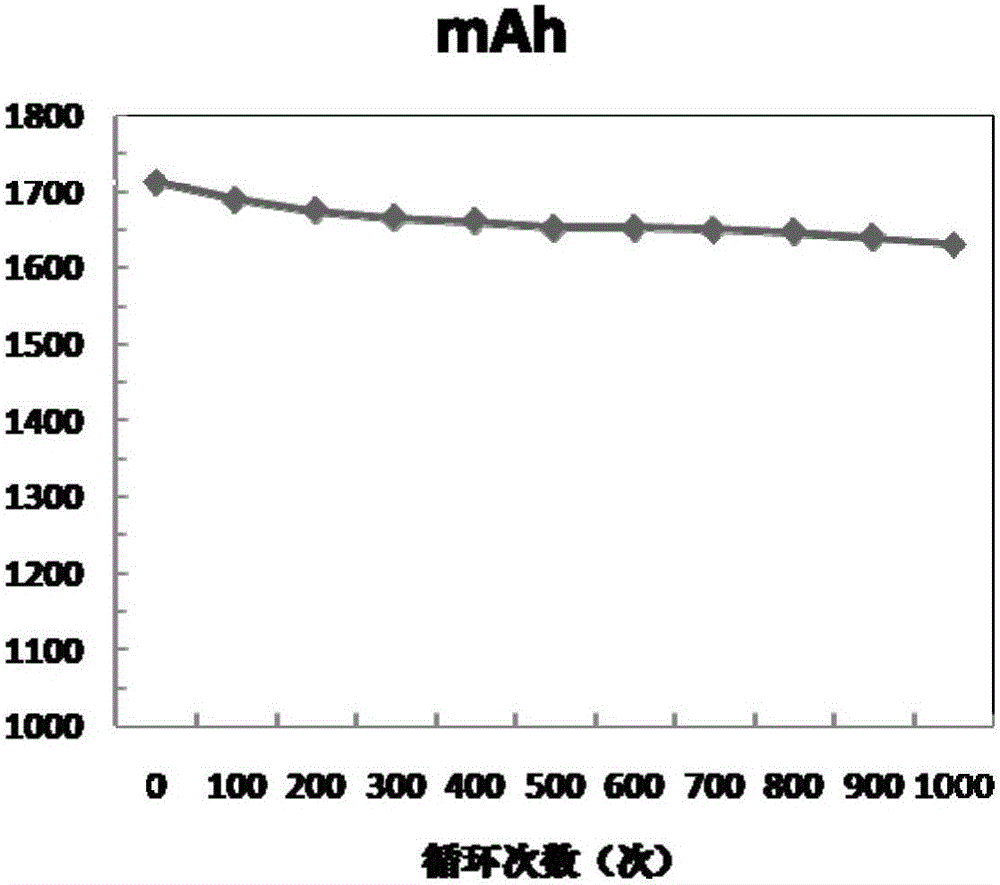

[0032] Vacuum-evaporate lithium on the surface of C-Cu composite current c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com