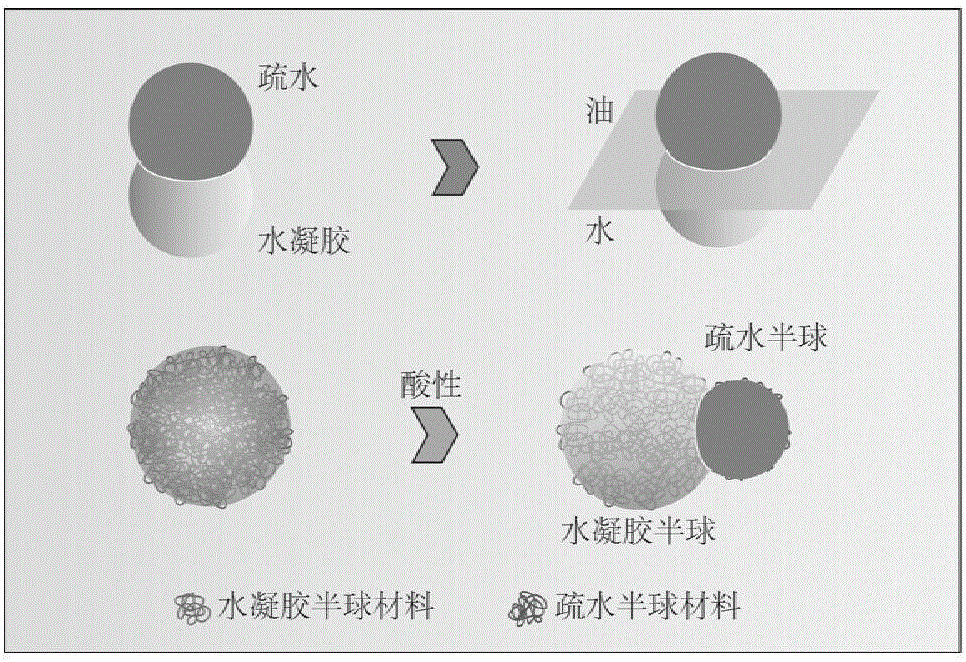

Hydrogel-hydrophobic Janus particle and preparation method thereof

A hydrogel, hydrophobic technology, applied in the field of microemulsion, can solve the problems of instability of microemulsion, achieve good biocompatibility and biodegradability, avoid direct contact, and solve the effect of instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

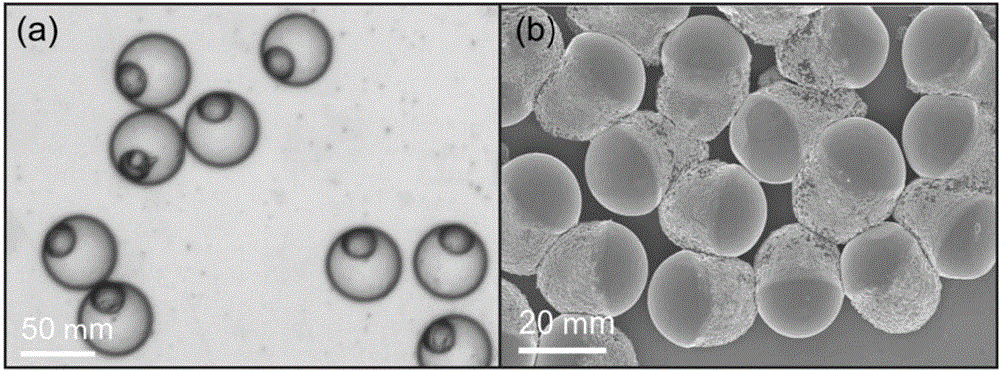

[0039] Example 1: Preparation of hydrogel-hydrophobic Janus particles

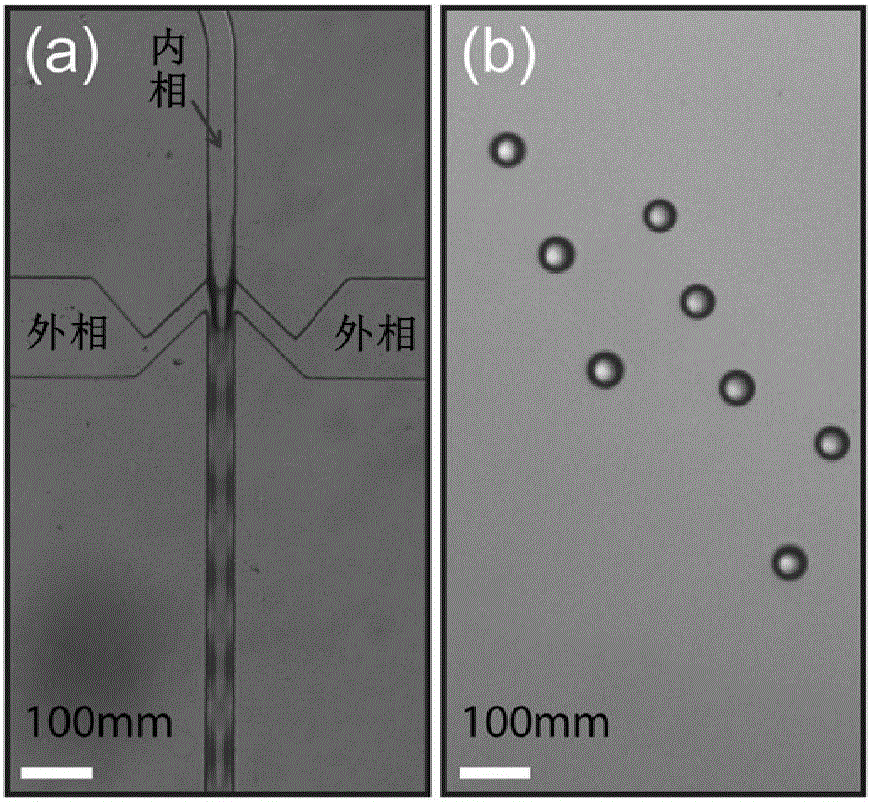

[0040] (1) First, the flow-focusing PDMS microfluidic device used in the present invention is produced by soft photolithography: a layer of photosensitive material is coated on the silicon substrate, and a part of the area is exposed through a mask, and the photosensitive material imaging agent is used to obtain the microfluidic device on the silicon substrate. The channel structure, this channel structure has an inner phase inlet, an outer phase inlet and an outlet, and the outer phase inlet is divided into two channels and is symmetrically distributed on the left and right sides of the inner phase inlet; then use PDMS (polydimethylsiloxane ) materials to replicate the channel structure, and bond PDMS and glass substrates to make microfluidic devices through plasma and heat treatment; finally, surface hydrophobic treatment is carried out on the microfluidic devices to obtain flow-focusing PDMS microfluidic...

Embodiment 2

[0044] Example 2: Preparation of hydrogel-hydrophobic Janus particles

[0045](1) Dissolve 10.5 mg of sodium carbonate in 1 ml of water to obtain an alkaline solution; dissolve 80 mg of shellac in the above-mentioned alkaline solution to obtain a shellac solution; then dissolve 10 mg of sodium alginate in the above-mentioned shellac solution to obtain a mixed solution; finally, 0.2 mg calcium carbonate nanoparticles were dispersed into the above mixed solution by ultrasonic to obtain the final mixed solution.

[0046] Take 1ml of the final mixed solution prepared in step (2) as the internal phase, and pass it into the internal phase inlet of the flow-focusing PDMS microfluidic device prepared in Example (1). Take 2ml of the fluorinated ether solution containing 0.9wt% PEG-Krytox-PEG surfactant (the molar mass concentration of HFE7500 is 3mol / L) and pass it into the flow focusing PDMS microfluidic device prepared in Example (1) as the external phase The foreign entrance. Then...

Embodiment 3

[0048] Example 3: Preparation of hydrogel-hydrophobic Janus particles

[0049] (1) Dissolve 16.5 mg of sodium carbonate in 1 ml of water to obtain an alkaline solution; dissolve 160 mg of shellac in the above-mentioned alkaline solution to obtain a shellac solution; then dissolve 20 mg of sodium alginate in the above-mentioned shellac solution to obtain a mixed solution; finally, 2 mg of calcium carbonate nanoparticles were dispersed into the above mixed solution by ultrasonic to obtain the final mixed solution.

[0050] Take 1ml of the final mixed solution prepared in step (2) as the internal phase, and pass it into the internal phase inlet of the flow-focusing PDMS microfluidic device prepared in Example (1). Get 10ml of the fluorinated ether solution containing 1.2wt% PEG-Krytox-PEG surfactant (the molar mass concentration of HFE7500 is 3.5mol / L) as the external phase into the flow-focusing PDMS microfluidic device prepared in Example (1). The outer phase entrance of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com