Nylon-fiber-reinforced anti-impact diatom ooze material and preparation method thereof

A technology of nylon fiber and diatom mud, which is applied in the field of building materials, can solve problems such as easy cracking, loss of diatom mud breathing and filtration, poor stretching performance, etc., to achieve enhanced adsorption adhesion and mechanical meshing force, and enhanced water retention Moisturizing effect, stress concentration reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

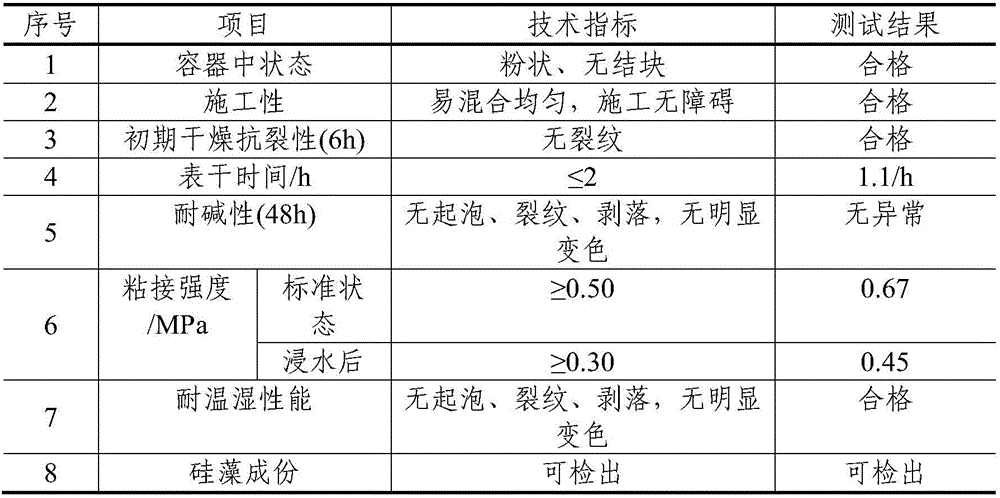

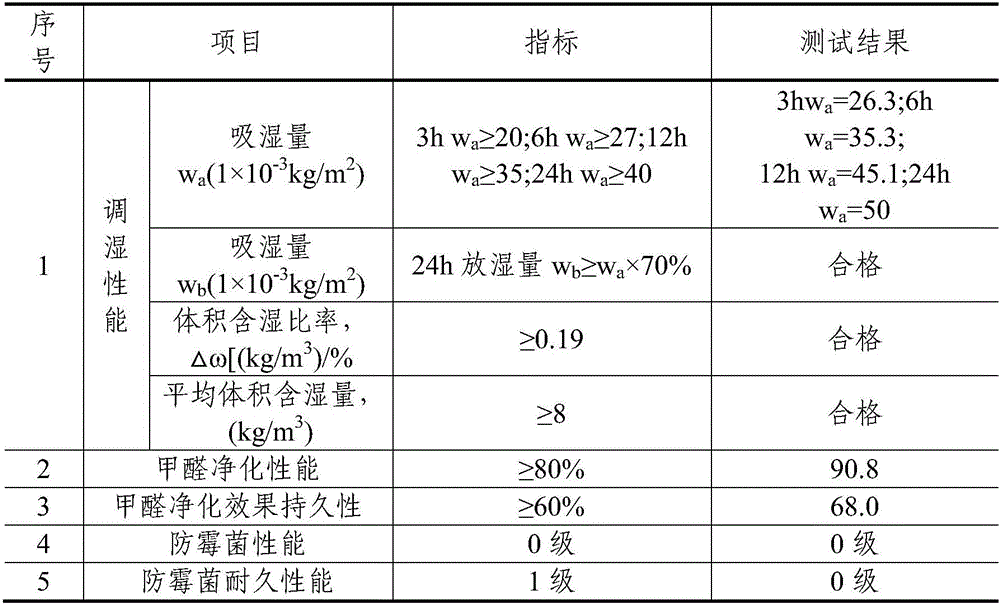

Embodiment 1

[0032] The preparation method of the nylon fiber reinforced impact-resistant diatom ooze material of the present embodiment is prepared according to the following steps:

[0033] Step 1. Preparation of mixed powder: 35 parts of diatomite with a silicon content of 94%, 35 parts of heavy calcium carbonate with a particle size of 150 μm, 20 parts of ash calcium powder with a particle size of 120 μm, 13 parts of quartz sand with a particle size of 150 μm, 2 parts of anion powder with a particle size of 13 μm, 2 parts of sodium carboxymethyl starch with a viscosity of 80000 and 0.4 part of cornstarch with a particle size of 140 μm are sufficiently uniform to prepare a mixed powder;

[0034] Step 2. Preparation of nano-titanium dioxide mixed solution: after mixing 2 parts of rutile nano-titanium dioxide powder with water, ultrasonically disperse at 60KHz until uniform;

[0035] Step 3, preparing mixed slurry: adding the mixed powder in step 1 to the nano-titanium dioxide mixed solut...

Embodiment 2

[0039] The preparation method of the nylon fiber reinforced impact-resistant diatom ooze material of the present embodiment is prepared according to the following steps:

[0040] Step 1, preparation of mixed powder: 15 parts of diatomite with a silicon content of 91%, 25 parts of heavy calcium carbonate with a particle size of 40 μm, 14 parts of ash calcium powder with a particle size of 150 μm, 20 parts of quartz sand with a particle size of 200 μm, 1 Anion powder of 9 μm in particle size, 1.5 parts of sodium starch glycolate with a viscosity of 20000, 1 part of hydroxypropyl methylcellulose with a viscosity of 200000 and 0.5 parts of potato starch with a particle size of 120 μm are fully uniform to obtain a mixed powder;

[0041] Step 2. Preparation of nano-titanium dioxide mixed solution: after mixing 4 parts of anatase nano-titanium dioxide powder with water, ultrasonically disperse at 50KHz until uniform;

[0042] Step 3, preparing mixed slurry: adding the mixed powder in...

Embodiment 3

[0046]The preparation method of the nylon fiber reinforced impact-resistant diatom ooze material of the present embodiment is prepared according to the following steps:

[0047] Step 1, preparation of mixed powder: 25 parts of diatomite with a silicon content of 92%, 20 parts of ground calcium carbonate with a particle size of 90 μm, 12 parts of ash calcium powder with a particle size of 23 μm, 8 parts of quartz sand with a particle size of 600 μm, 2 parts of negative ion powder with a particle size of 3.3 μm, 0.6 part of sodium carboxymethyl starch with a viscosity of 100000, 0.6 part of sodium carboxymethylcellulose with a viscosity of 140000, 0.6 part of hydroxypropyl methylcellulose with a viscosity of 50000 and 0.1 The cassava pregelatinized starch with a particle size of 90 μm is fully uniform to obtain a mixed powder;

[0048] Step 2. Preparation of nano-titanium dioxide mixed solution: after mixing 5 parts of anatase nano-titanium dioxide powder with water, ultrasonica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com