Zirconia ceramic sheet and its preparation method, cover plate of induction identification module, its preparation method and application

A technology of zirconia ceramics and zirconia powder, applied in the field of ceramic materials, can solve the problems of zirconia ceramic grain growth, lower production efficiency, and lower bending strength of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

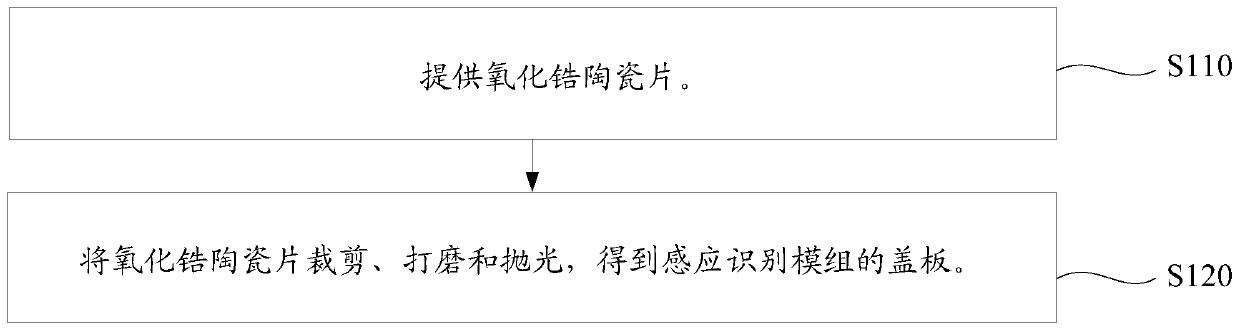

[0025] Such as figure 1 As shown, a method for preparing a cover plate of an inductive identification module in an embodiment, the inductive identification module may be, for example, a fingerprint identification module, and the method for preparing a cover plate of the inductive identification module includes the following steps:

[0026] Step S110: providing a zirconia ceramic sheet.

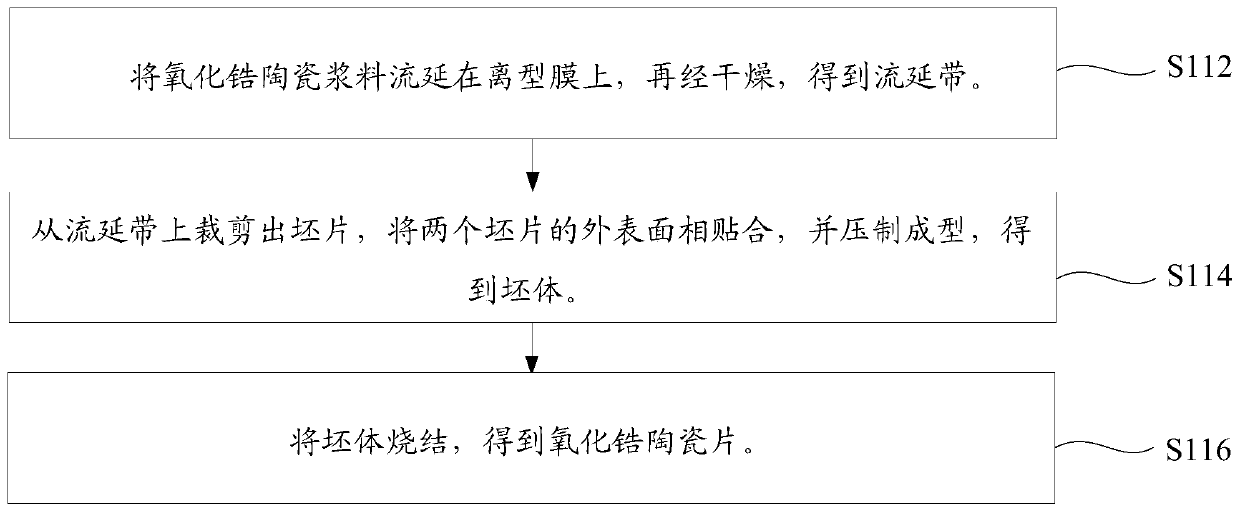

[0027] Please also refer to figure 2 , wherein, the preparation method of zirconia ceramic sheet comprises the following steps:

[0028] Step S112: cast the zirconia ceramic slurry on the release film, and then dry to obtain the cast tape.

[0029] Wherein, the casting belt has a bottom surface opposite to the release film and an outer surface opposite to the bottom surface.

[0030] Wherein, the zirconia ceramic slurry in step S112 can be prepared by the following steps: mixing zirconia powder, solvent, dispersant, binder and plasticizer to obtain a viscosity of 1Pa·s-10Pa·s, solid The m...

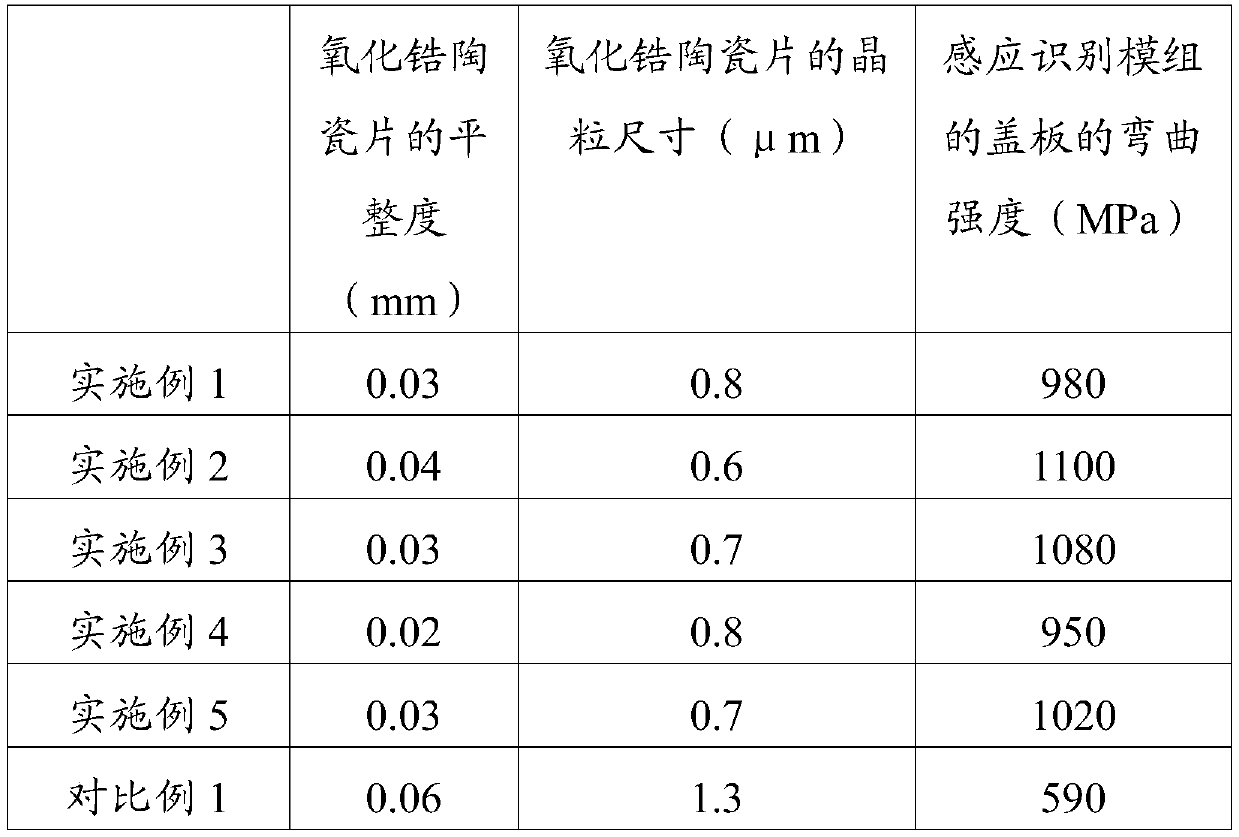

Embodiment 1

[0056] The preparation process of the cover plate of the induction recognition module in this embodiment is as follows:

[0057] (1) Mix zirconia powder, solvent and dispersant by ball milling for 4 hours, then add binder and plasticizer and continue ball milling for 8 hours, then add defoamer, ball mill for 1 hour, and finally vacuum degassing for 1 hour, A zirconia ceramic slurry with a viscosity of 8.3 Pa·s and a mass percentage of solid phase of 55% was obtained. Among them, the median particle size of the zirconia powder is 0.5 micron to 0.6 micron, wherein the binder is polyvinyl butyral; the dispersant is castor oil; the plasticizer is dibutyl phthalate; the solvent It is ethanol, and the defoaming agent is n-butanol; the mass ratio of binder to zirconia powder is 5:100; the mass ratio of dispersant to zirconia powder is 2:100; the plasticizer and zirconia powder The mass ratio of the solvent to the zirconia powder is 20:100; the mass ratio of the solvent to the zircon...

Embodiment 2

[0071] The preparation process of the cover plate of the induction recognition module in this embodiment is as follows:

[0072] (1) Mix zirconia powder, solvent and dispersant by ball milling for 3 hours, then add binder and plasticizer to continue ball milling for 10 hours, then add defoaming agent, ball mill for 0.5 hours, and finally vacuum defoam for 2 hours, A zirconia ceramic slurry with a viscosity of 7.5 Pa·s and a mass percentage of solid phase of 51.9% was obtained. Among them, the median particle size of the zirconia powder is 0.5 micron to 0.6 micron, and the binder is polyvinyl butyral; the dispersant is glyceryl trioleate; the plasticizer is dibutyl phthalate ester; the solvent is xylene, and the defoaming agent is n-butanol; the mass ratio of the binder to the zirconia powder is 10:100; the mass ratio of the dispersant to the zirconia powder is 0.5:100; the plasticizer and the zirconia powder are 0.5:100; The mass ratio of zirconia powder is 25:100; the mass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com