A kind of preparation method of co-growth of SIC nanowire and SIC-Mosi2-CRSi2 coating

A sic-mosi2-crsi2 and nanowire technology, applied in the field of C/C composite material manufacturing, can solve problems such as coating damage, achieve the effects of reducing thermal damage, alleviating thermal stress mismatch, and reducing cracking tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

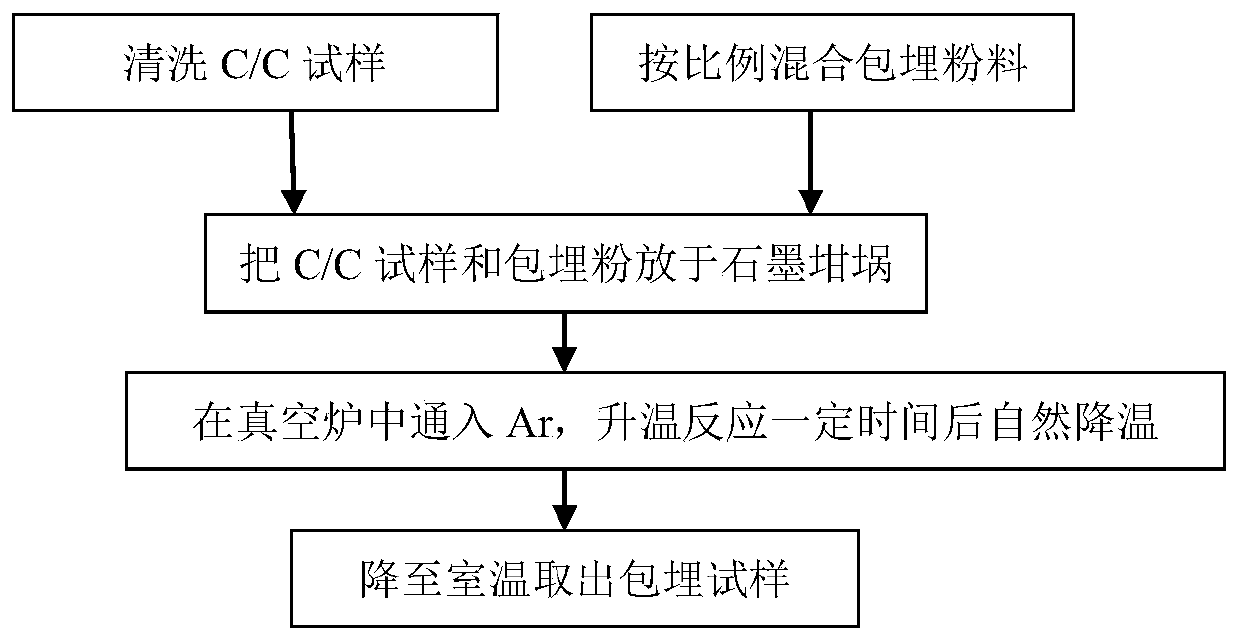

[0024] Step 1: Grind and polish the C / C composite material with No. 400, No. 800, and No. 1000 sandpaper, then ultrasonically clean it with water and absolute ethanol for 15-20 minutes, and dry it in a drying oven for later use;

[0025] Step 2: Weigh MoSi with a mass percentage of 10-20% respectively 2 Powder, 65-80% of Si powder, 10-20% of Cr powder, 5%-10% of C powder, put in the turpentine ball ink tank, take different numbers of agate balls with different diameters and put them into the ball mill tank, in the ball mill Go up the ball mill and mix for 2 hours to get the embedding powder, dry it for 12 hours and set aside;

[0026] Step 3: Put the above 1 / 3 of the embedding powder into the graphite crucible, then put the pretreated C / C composite material, and then put the above 1 / 3 of the embedding powder to make the C / C composite material cover.

[0027] Step 4: Put the graphite crucible into a vacuum heating furnace, raise the furnace temperature from room temperature t...

Embodiment 2

[0029] Step 1: Grind and polish the C / C composite material with No. 400, No. 800, and No. 1000 sandpaper, then ultrasonically clean it with water and absolute ethanol for 15-20 minutes, and dry it in a drying oven for later use;

[0030] Step 2: Weigh 60-80% silicon powder, 10-25% carbon powder, and 5-15% aluminum oxide powder in the turpentine ball ink tank, and put different numbers and diameters of agate balls into the In the ball mill tank, ball mill and mix on a ball mill for 2 hours to obtain embedding powder, dry for 12 hours and set aside;

[0031] Step 3: Put the above-mentioned powder into the graphite crucible, bury the spare carbon / carbon composite material in the mixed powder respectively, then put the graphite crucible into the vertical vacuum furnace, and pass the argon gas into the whole process as the protective atmosphere , the temperature rise rate of the vertical vacuum furnace is controlled at 5°C / min. When the furnace temperature rises to 2000°C, it is ke...

Embodiment 3

[0036] Step 1: Grind and polish the C / C composite material with No. 400, No. 800, and No. 1000 sandpaper, then ultrasonically clean it with water and absolute ethanol for 15-20 minutes, and dry it in a drying oven for later use;

[0037] Step 2: Weigh MoSi with a mass percentage of 10-20% respectively 2 Powder, 65-80% of Si powder, 10-20% of Cr powder, 5%-10% of C powder, put in the turpentine ball ink tank, take different numbers of agate balls with different diameters and put them into the ball mill tank, in the ball mill Go up the ball mill and mix for 2 hours to get the embedding powder, dry it for 12 hours and set aside;

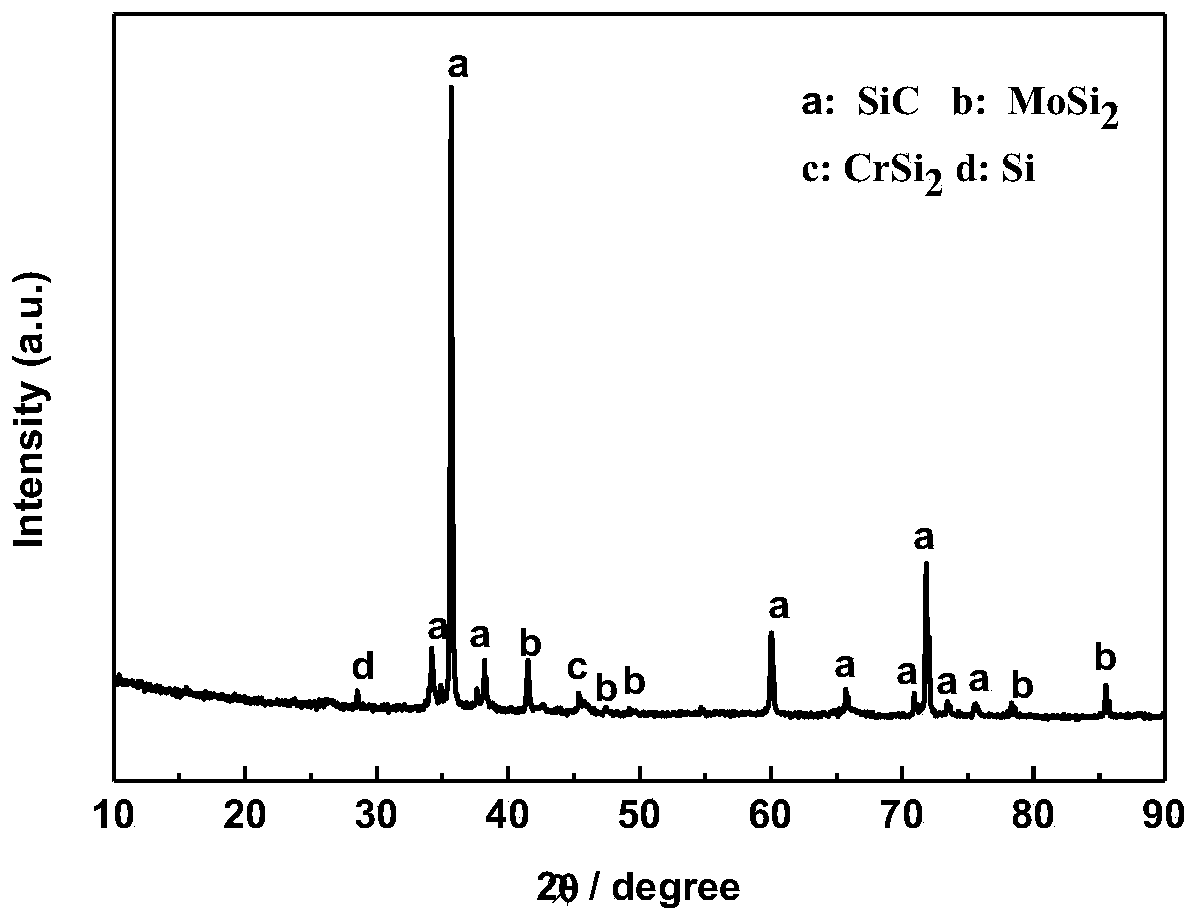

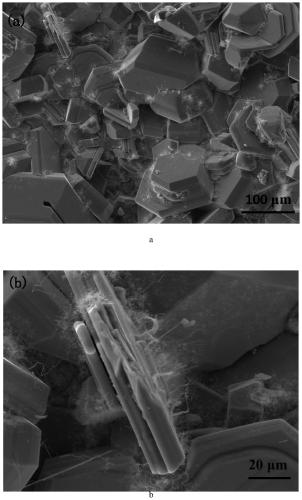

[0038] Step 3: Put the above-mentioned powder into the graphite crucible, bury the carbon / carbon composite material in the mixed powder respectively, then put the graphite crucible into the vertical vacuum furnace, and put Ar as the protective atmosphere in the whole process, vertical The temperature rise rate of the vacuum furnace was controlled at 5°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com