A method for extracting high-purity marine phospholipids from Antarctic krill

An Antarctic krill, high-purity technology, applied in the direction of edible phospholipid composition, chemical instruments and methods, compounds of group 5/15 elements of the periodic table, etc., can solve the problems of robbing food resources, affecting the quality of phospholipids, and high operating costs , to achieve the effects of good mechanical strength of the filler, easy operation and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

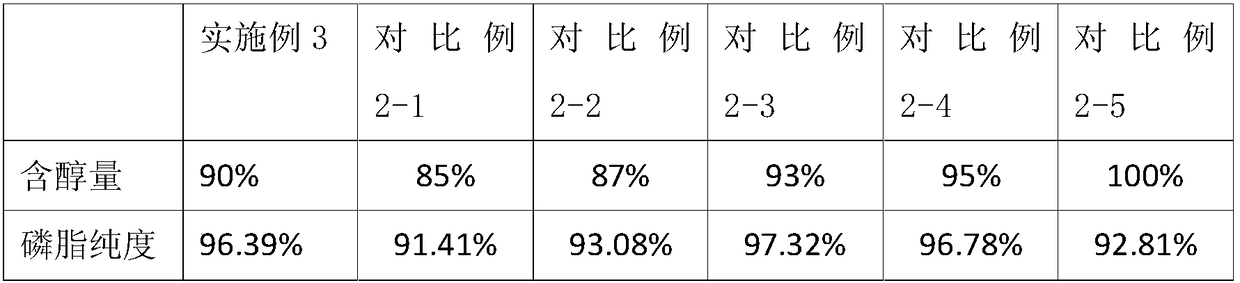

[0037] Weigh 100g of cryopreserved Antarctic krill, add 50mL of water, pulverize and homogenize for 18min, adjust the pH to 6.5 with acetic acid-sodium acetate buffer solution, heat to 40°C, add 0.5g of compound enzyme, and hydrolyze for about 3h; Centrifuge the solid part through 1000mL of 93% ethanol solution (sodium acetate adjusts its pH to 9.0), ultrasonically extract twice at 30°C, each time for 30min, and the ultrasonic frequency is 30KHz, combine the extracts, and filter under reduced pressure. Concentrate under reduced pressure at 45°C to obtain the extract concentrate; stir the extract concentrate at a speed of 60 revolutions per minute, heat the temperature to 35°C, reduce the stirring speed to 25 revolutions per minute, slowly and evenly add distilled water, the amount of water is 3% of oil weight, water temperature 30°C, water mixing time is 15min, after mixing water, the stirring speed is restored to 60 rpm, stop stirring when the flocs precipitate, let stand for ...

Embodiment 2

[0040] Weigh 100g of fresh Antarctic krill, add 100mL of water, pulverize and homogenize for 12min, adjust the pH to 6.5 with acetic acid-sodium acetate buffer solution, heat to 45°C, add 0.7g of compound enzyme, and hydrolyze for about 4h; centrifuge the enzymatic solution, The solid part was subjected to 1200mL of 95% ethanol solution (sodium bicarbonate to adjust its pH to 9.0), ultrasonically extracted twice at room temperature, each time for 15min, and the ultrasonic frequency was 30KHz, the combined extracts were filtered under reduced pressure, and the filtrate was reduced by 45°C. Concentrate under pressure to obtain the extract concentrate; stir the extract concentrate at a speed of 60 revolutions per minute, heat the temperature to 35°C, reduce the stirring speed to 25 revolutions per minute, and slowly and evenly mix in distilled water, the amount of water added is the weight of the oil 3%, the water temperature is 30°C, and the water mixing time is 15 minutes. After...

Embodiment 3

[0042] Weigh 100g of fresh Antarctic krill, add 200mL of water, pulverize and homogenize for 8 minutes, adjust the pH to 6.5 with acetic acid-sodium acetate buffer solution, heat to 43°C, add 0.8g of compound enzyme, and hydrolyze for about 2 hours; the enzymatic solution is separated from solid and liquid , the solid part was subjected to 600mL of 90% ethanol solution (sodium bicarbonate adjusted its pH to 10.0), ultrasonically extracted twice at 35°C, each time for 20min, and the ultrasonic frequency was 40KHz, the combined extracts were filtered under reduced pressure, and the filtrate was subjected to 43 Concentrate under reduced pressure at ℃ to obtain the extract concentrate; stir the extract concentrate at a speed of 60 rpm, heat the temperature to 35°C, reduce the stirring speed to 25 rpm, slowly and evenly mix in distilled water, the amount of water mixed is oil 3% by weight, water temperature 30°C, water mixing time 15min, after mixing water, the stirring speed is res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com