Preparation method of mullite fiber/epoxy resin composite material

A technology of mullite fiber and epoxy resin, applied in the field of preparation of mullite fiber/epoxy resin composite material, can solve the problem of material thermal conductivity, limited mechanical properties, difficult to form a thermal network, mullite fiber It is difficult to uniformly disperse and other problems, so as to achieve the effect of improving high and low temperature mechanical properties, easy operation and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

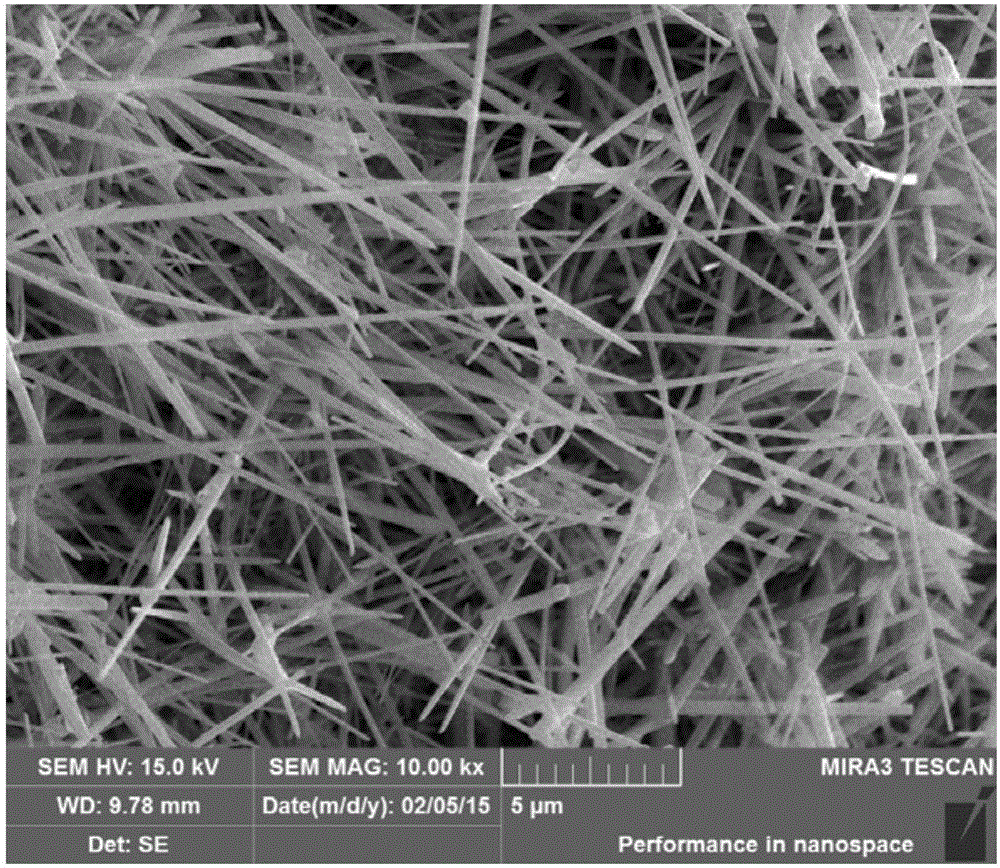

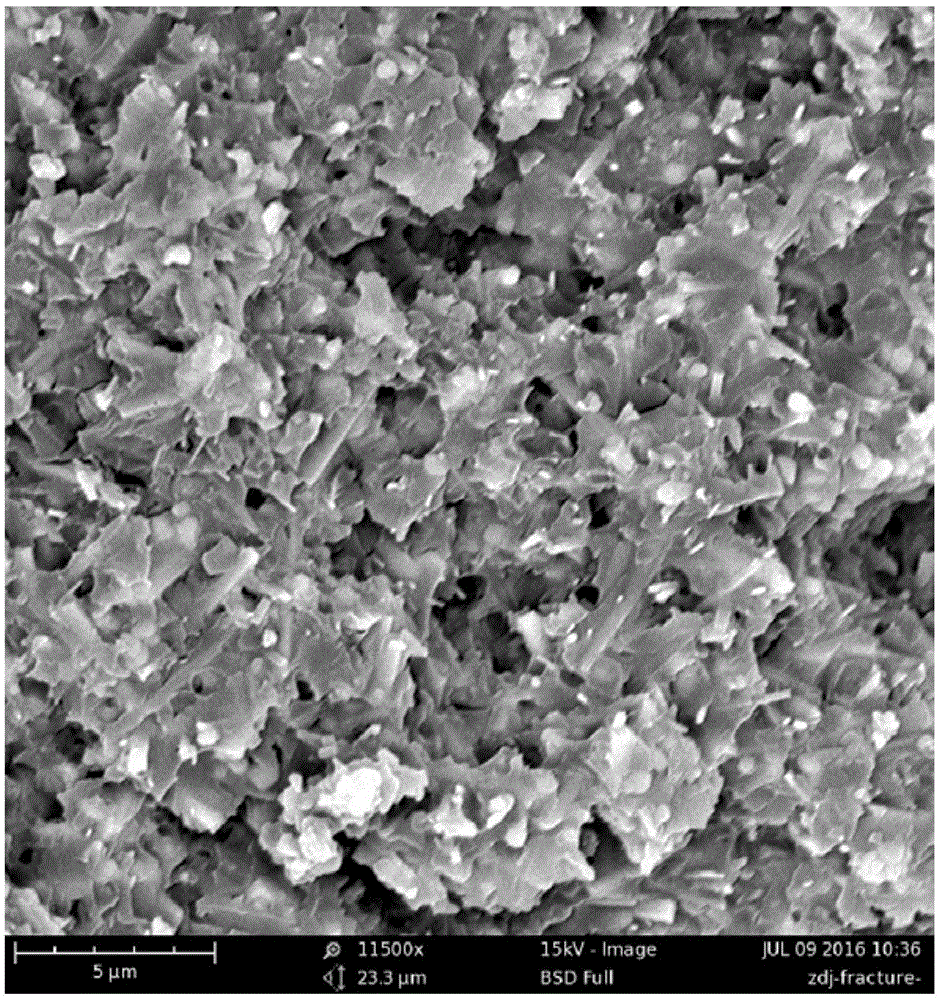

Image

Examples

Embodiment 1

[0032] 1. Add tetraethyl orthosilicate to ethanol at a concentration of 0.8mol / L, then add deionized water, the molar ratio of water to tetraethyl orthosilicate is 3:1, and put the prepared solution at room temperature Under magnetic stirring for 3 days, a transparent silica sol was obtained;

[0033] 2. SiO 2 :Al 2 o 3 : AlF 3 The mass ratio of 1:2:0.8 will correspond to the ratio of Al 2 o 3 Powder and AlF 3 Add the powder into ethanol to obtain a mixed slurry, use zirconia balls as grinding balls, and ball mill for 24 hours to obtain a uniform slurry;

[0034] 3 Mix the corresponding proportion of silica sol and alumina slurry evenly, add 5 mol / L ammonia water, the pH value is 6, and let it stand for 2 hours to obtain 3Al 2 o 3 2SiO2 2 gel, then put the gel into an oven, keep it at 70°C for 24h, and grind it in a crucible to get 3Al 2 o 3 2SiO2 2 Type mullite precursor powder;

[0035] 4. The 3Al obtained in step 3 2 o 3 2SiO2 2 The type mullite precursor po...

Embodiment 2

[0038] 1. Add tetraethyl orthosilicate to ethanol at a concentration of 0.6mol / L, then add deionized water, the molar ratio of water to tetraethyl orthosilicate is 4:1, and put the prepared solution at room temperature Under magnetic stirring for 5 days, a transparent silica sol was obtained;

[0039] 2. SiO 2 :Al 2 o 3 : AlF 3 The mass ratio of 1:3:1.5 will correspond to the ratio of Al 2 o 3 Powder and AlF 3 Add the powder into ethanol to obtain a mixed slurry, use zirconia balls as grinding balls, and ball mill for 24 hours to obtain a uniform slurry;

[0040] 3 Mix the corresponding proportion of silica sol and alumina slurry evenly, add ammonia water with a concentration of 10mol / L, the pH value is 7, and stand for 3 hours to obtain 3Al 2 o 3 2SiO2 2 Gel, and then put the gel in an oven, keep it at 90°C for 12h, and grind it in a crucible to get 3Al 2 o 3 2SiO2 2 Type mullite precursor powder;

[0041] 4. The 3Al obtained in step 3 2 o 3 2SiO2 2 The type m...

Embodiment 3

[0044] 1. Add tetraethyl orthosilicate to ethanol at a concentration of 0.7mol / L, then add deionized water, the molar ratio of water to tetraethyl orthosilicate is 5:1, and put the prepared solution at room temperature Under magnetic stirring for 4 days, a transparent silica sol was obtained;

[0045] 2. SiO 2 :Al 2 o 3 : AlF 3 The mass ratio of 1:2.5:1 will correspond to the proportion of Al 2 o 3 Powder and AlF 3 Add the powder into ethanol to obtain a mixed slurry, use zirconia balls as grinding balls, and ball mill for 24 hours to obtain a uniform slurry;

[0046] 3. Mix the corresponding proportion of silica sol and alumina slurry evenly, add ammonia water with a concentration of 8mol / L, the pH value is 6.5, and stand for 2.5h to obtain 3Al 2 o 3 2SiO2 2 gel, and then put the gel in an oven, keep it at 80°C for 18h, and grind it in a crucible to get 3Al 2 o 3 2SiO2 2 Type mullite precursor powder;

[0047] 4. The 3Al obtained in step 3 2 o 3 2SiO2 2 The ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com