Fungus-based biomass fireproof material with bagasse as main material and preparation method thereof

A fireproof material and bagasse technology, applied in fireproof coatings and other directions, can solve problems such as air and natural environment pollution, and achieve the effects of environmental protection, simple preparation method and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

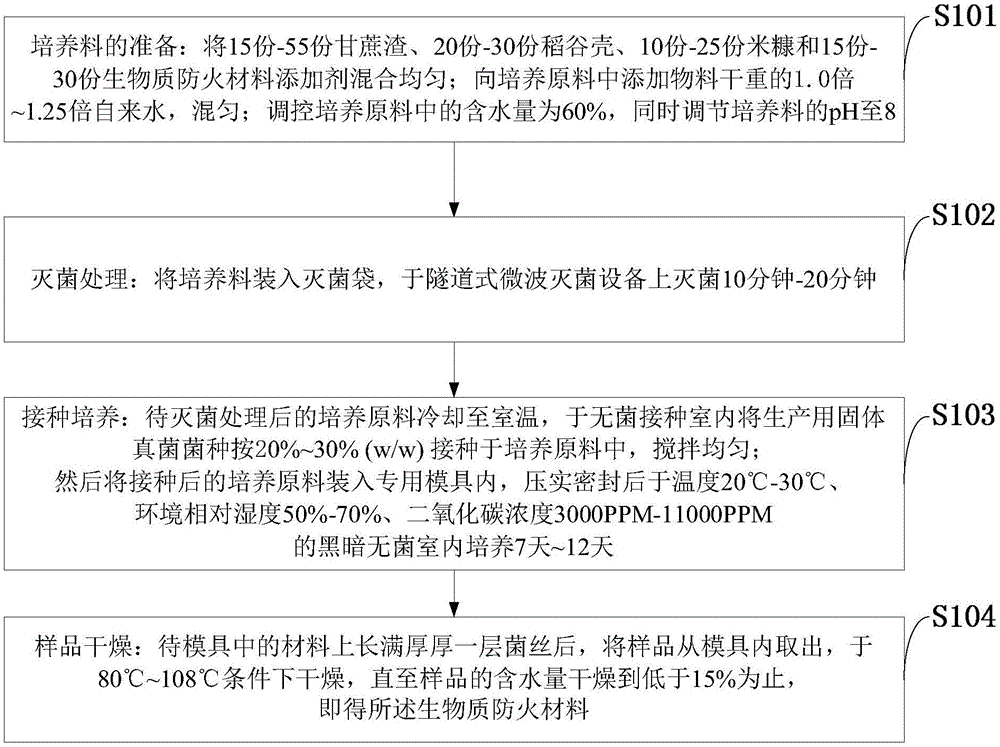

[0037] Such as figure 1 As shown, the preparation method of the fungal-based biomass fireproof material based on bagasse as the main ingredient provided by the embodiment of the present invention comprises the following steps:

[0038]S101: Preparation of culture material: Mix 15-55 parts of bagasse, 20-30 parts of rice husk, 10-25 parts of rice bran and 15-30 parts of biomass fireproof material additive; add materials to the culture raw material 1.0-1.25 times the dry weight of tap water, mix well; adjust the water content in the culture material to 55%-60%, and adjust the pH of the culture material to 8 at the same time;

[0039] S102: Sterilization treatment: put the culture material into a sterilization bag, and sterilize it on the tunnel microwave sterilization equipment for 10 minutes to 20 minutes;

[0040] S103: Inoculation and cultivation: cool the sterilized culture material to room temperature, inoculate 20%-30% (w / w) solid fungal strains for production into the cu...

Embodiment 1

[0046] The specific steps of the preparation method of the fungal-based biomass fireproof material with bagasse as the main ingredient provided by the embodiment of the present invention are as follows:

[0047] (1) Preparation of compost: Mix 43 parts of bagasse, 22 parts of rice husks, 18 parts of rice bran and 17 parts of biomass fireproof material additives; add tap water 1.25 times of the dry weight of materials to the culture raw materials, mix well; regulate The water content in the culture material is 60%, and the pH of the culture material is adjusted to 8 at the same time;

[0048] Bagasse is the fresh bagasse after sugar cane is squeezed. The diameter of bagasse is 1mm-30mm, and the proportions of bagasse with lengths of 1mm-15mm, 15mm-20mm and 20mm-30mm are 20%, 50% and 30% respectively.

[0049] (2) Sterilization treatment: put the culture material into a sterilization bag, and sterilize it on the tunnel microwave sterilization equipment for 18 minutes;

[0050] ...

Embodiment 2

[0054] The specific steps of the preparation method of the fungal-based biomass fireproof material with bagasse as the main ingredient provided by the embodiment of the present invention are as follows:

[0055] (1) Preparation of compost: Mix 50 parts of bagasse, 20 parts of rice husks, 15 parts of rice bran and 15 parts of biomass fireproofing material additive; add 1.25 times of tap water to the culture raw material, mix well; The water content in the culture material is 60%, and the pH of the culture material is adjusted to 8 at the same time;

[0056] Bagasse is the fresh bagasse after sugar cane is squeezed. The diameter of bagasse is 1mm-30mm, and the proportions of bagasse with lengths of 1mm-15mm, 15mm-20mm and 20mm-30mm are 20%, 50% and 30% respectively.

[0057] (2) Sterilization treatment: put the culture material into a sterilization bag, and sterilize it on the tunnel microwave sterilization equipment for 18 minutes;

[0058] (3) Inoculation culture: the culture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com