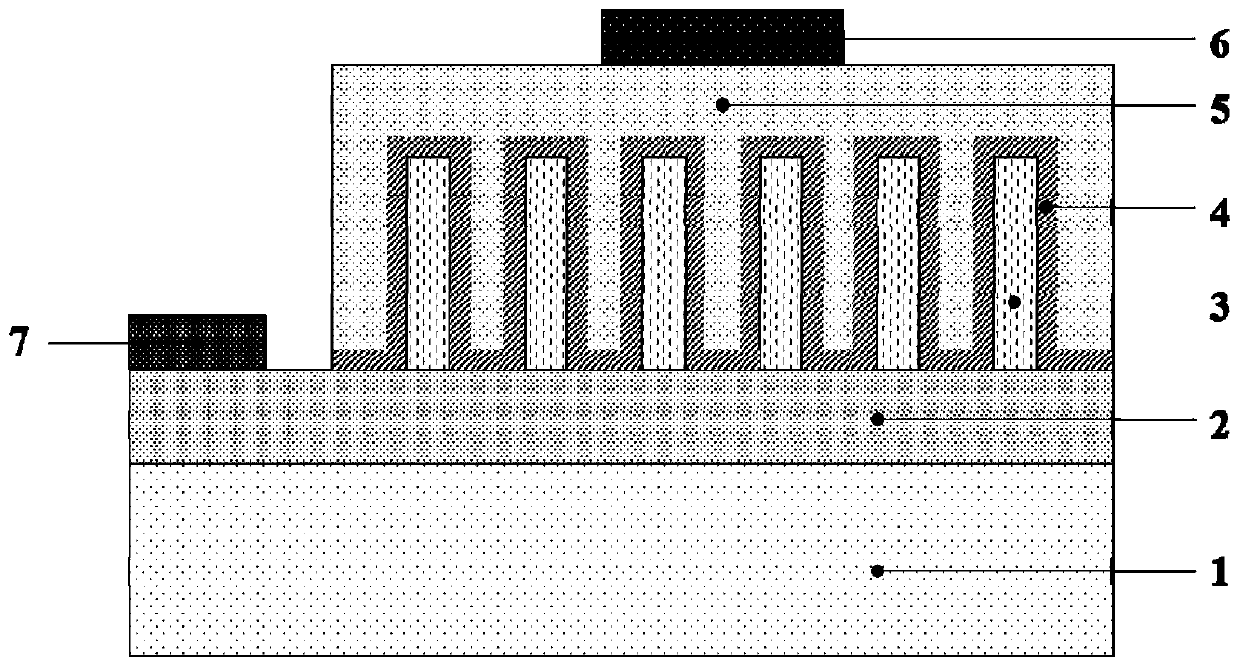

ZnO-based nanorod/quantum well composite ultraviolet light-emitting diode and preparation method thereof

A technology of light-emitting diodes and nanorods, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of limiting the application of ZnO-based ultraviolet light emitters, low quantum efficiency of light-emitting diodes, poor interface quality, deep-level light emission, etc. Polarization effect, the effect of improving the quality of materials and interfaces, and improving the rate of radiation recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

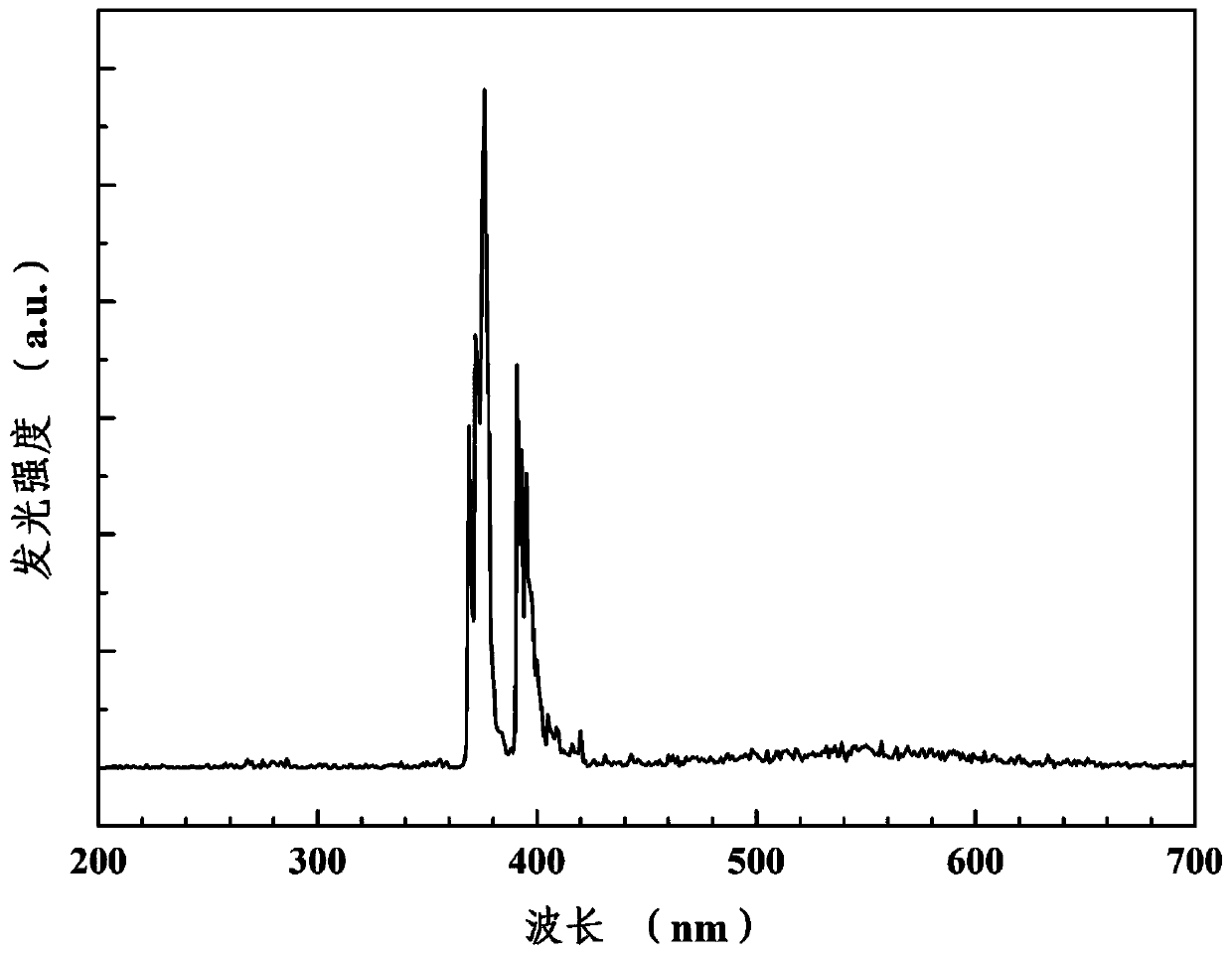

Embodiment 1

[0040] 1) Substrate cleaning: use sapphire as the substrate, cut it into a size of 15mm×15mm, ultrasonically clean it with acetone, alcohol and deionized water for 3 minutes, and finally use N 2 blow dry.

[0041] 2) Preparation of n-type ZnO thin film layer: Put the sapphire substrate after surface cleaning into the growth chamber of the radio frequency magnetron sputtering system, and the growth chamber is evacuated to the background pressure of 5×10 -4 Pa, heating the substrate to a temperature of 200°C. AZO ceramic target (ZnO:Al ceramic target) was selected as the target material for depositing n-type ZnO thin film layer. Before coating, pre-sputter for 10 min to remove impurities on the surface of the target, and then use radio frequency magnetron sputtering to deposit n-type ZnO thin film on the sapphire substrate. The temperature of the deposition substrate is 200° C., the gas during deposition is argon, the pressure is 0.5 Pa, the sputtering power is 60 W, and the s...

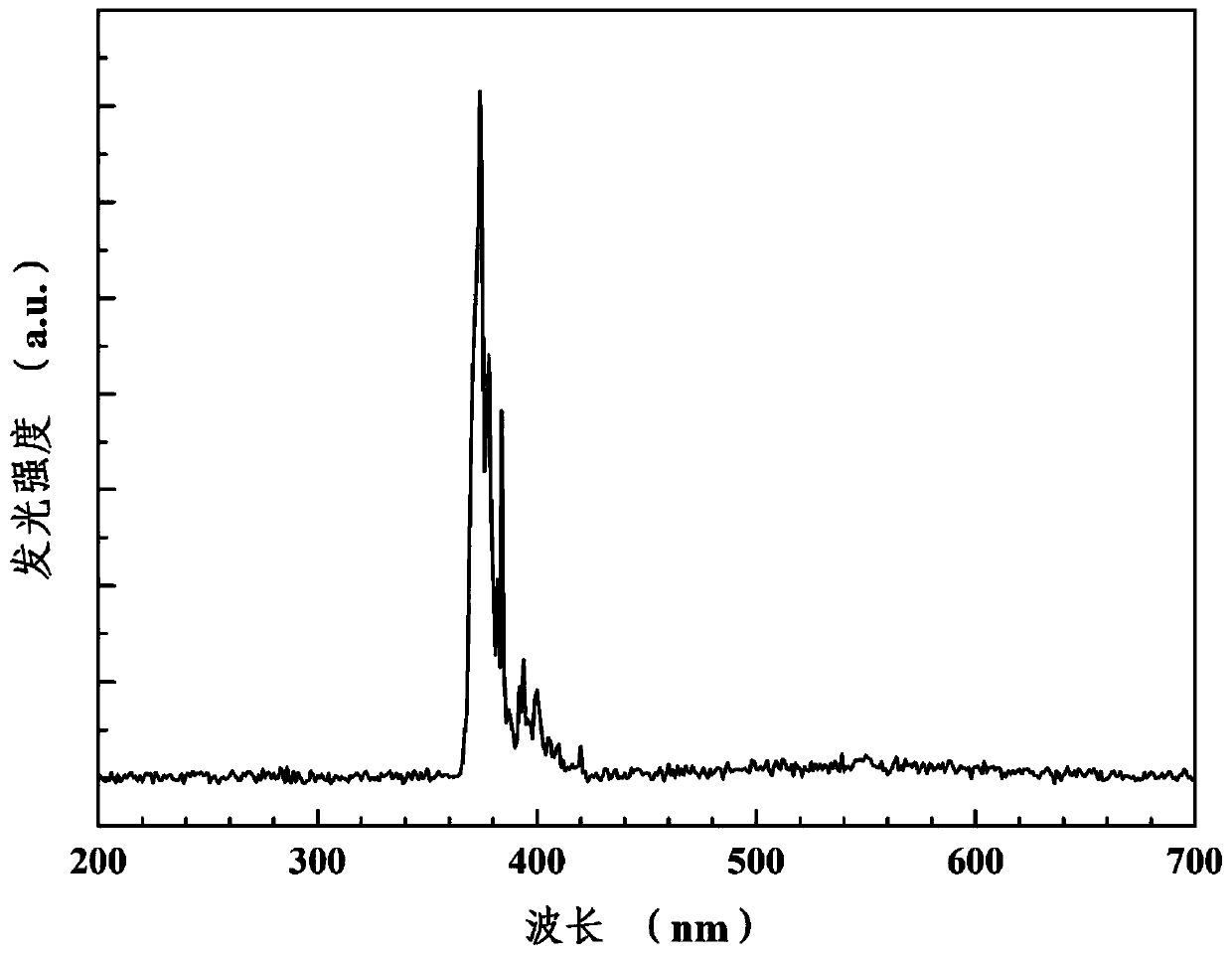

Embodiment 2

[0048] 1) Substrate cleaning: Use sapphire as the substrate, cut it into a size of 15mm×15mm, use acetone, alcohol, and deionized water to ultrasonically clean it for 3 minutes, and finally use N 2 blow dry.

[0049] 2) Preparation of n-type ZnO thin film layer: put the sapphire substrate after surface cleaning into the growth chamber of the radio frequency magnetron sputtering system, and vacuum the growth chamber to the background pressure of 1×10 -4 Pa, the substrate is heated to a temperature of 400 °C. AZO ceramic target is selected as the target material for depositing n-type ZnO thin film layer. Before coating, pre-sputter for 10 minutes to remove impurities on the surface of the target, and then use radio frequency magnetron sputtering to deposit an n-type ZnO thin film layer on the sapphire substrate; the temperature of the deposition substrate is 400 ° C, and the gas during deposition is Ar gas. The air pressure is 5.0Pa, the sputtering power is 150W, and the sputt...

Embodiment 3

[0056] 1) Substrate cleaning: Use sapphire as the substrate, cut it into a size of 15mm×15mm, use acetone, alcohol, and deionized water to ultrasonically clean it for 3 minutes, and finally use N 2 blow dry.

[0057] 2) Preparation of n-type ZnO thin film layer: put the sapphire substrate after surface cleaning into the growth chamber of the radio frequency magnetron sputtering system, and vacuum the growth chamber to the background pressure of 1×10 -3 Pa, heating the substrate to a temperature of 300°C. AZO ceramic target is selected as the target material for depositing n-type ZnO thin film layer. Before coating, pre-sputter for 10 min to remove impurities on the target surface. Then an n-type ZnO thin film layer was deposited on the sapphire substrate by radio frequency magnetron sputtering method. The temperature of the deposition substrate is 300° C., the gas during deposition is Ar gas, the gas pressure is 8.0 Pa, the sputtering power is 20 W, and the sputtering time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com