Antimony-germanium multilayer nano-composite phase-change material and preparation and application thereof

A composite phase-change material and nano-composite technology, which is applied in antimony-germanium multilayer nano-composite phase-change materials and its preparation and application fields, can solve problems such as large RESET current, unfavorable data stability, and low crystal resistivity, and achieve Fast crystallization rate, slow change in crystallinity, low melting point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

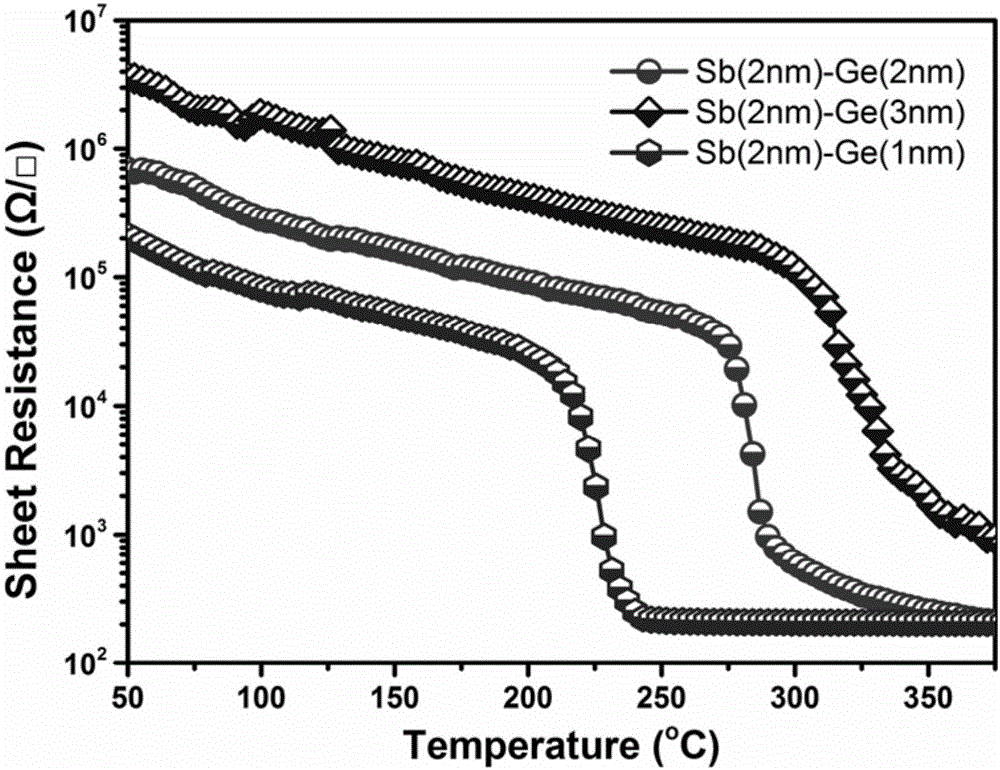

[0042] The total thickness of the Sb / Ge nanocomposite multilayer phase change film prepared in this example is 48-52nm, the general structure formula is [Sb(a)Ge(b)]x, and the specific structure has [Sb(2nm)Ge(1nm )] 16, [Sb(2nm)Ge(2nm)] 13, [Sb(2nm)Ge(3nm)] 10.

[0043] 1. Clean SiO2 2 / / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities:

[0044] (a) Place the substrate in an ethanol solution, and clean it ultrasonically for 15 minutes to remove dust particles and inorganic impurities on the surface of the substrate;

[0045] (b) The substrate is placed in an acetone solution, and ultrasonically cleaned for 15 minutes to remove organic impurities on the surface of the substrate;

[0046] (c) Place the substrate in deionized water, clean it ultrasonically for 15 minutes, and clean the surface again;

[0047] (d) Take out the substrate, dry it with pure Ar gas, and set it aside.

[0048] 2. Preparation of [Sb(a)Ge(b)]x films by sputte...

Embodiment 2

[0058] The total thickness of the Sb / Ge nanocomposite multilayer phase change film prepared in this example is 48nm, and the specific structure is [Sb(2nm)Ge(1nm)]16.

[0059] 1. Clean SiO2 2 / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities:

[0060] (a) Place the substrate in an ethanol solution, and clean it ultrasonically for 15 minutes to remove dust particles and inorganic impurities on the surface of the substrate;

[0061] (b) The substrate is placed in an acetone solution, and ultrasonically cleaned for 15 minutes to remove organic impurities on the surface of the substrate;

[0062] (c) Place the substrate in deionized water, clean it ultrasonically for 15 minutes, and clean the surface again;

[0063] (d) Take out the substrate, dry it with pure Ar gas, and set it aside.

[0064] 2. Preparation of [Sb(2nm)Ge(1nm)]16 film by sputtering method

[0065] (a) Put the Sb and Ge alloy targets, install the substrate, and then s...

Embodiment 3

[0074] The total thickness of the Sb / Ge nanocomposite multilayer phase change film prepared in this example is 52nm, and the specific structure is [Sb(2nm)Ge(2nm)]13.

[0075] 1. Clean SiO2 2 / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities:

[0076] (a) Place the substrate in an ethanol solution, and clean it ultrasonically for 15 minutes to remove dust particles and inorganic impurities on the surface of the substrate;

[0077] (b) The substrate is placed in an acetone solution, and ultrasonically cleaned for 15 minutes to remove organic impurities on the surface of the substrate;

[0078] (c) Place the substrate in deionized water, clean it ultrasonically for 15 minutes, and clean the surface again;

[0079] (d) Take out the substrate, dry it with pure Ar gas, and set it aside.

[0080] 2. Preparation of [Sb(2nm)Ge(2nm)]13 film by sputtering method

[0081] (a) Put Sb and Ge single target materials, install the substrate, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com