Ganoderma spore powder granules

A technology of Ganoderma lucidum spore powder and granules, applied in the fields of plant raw materials, food science, application, etc., can solve the problems of sticking to the surface of the container or packaging, affecting the edible, poor fluidity of the spore powder, etc. Time-consuming and energy-consuming, high wall-breaking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

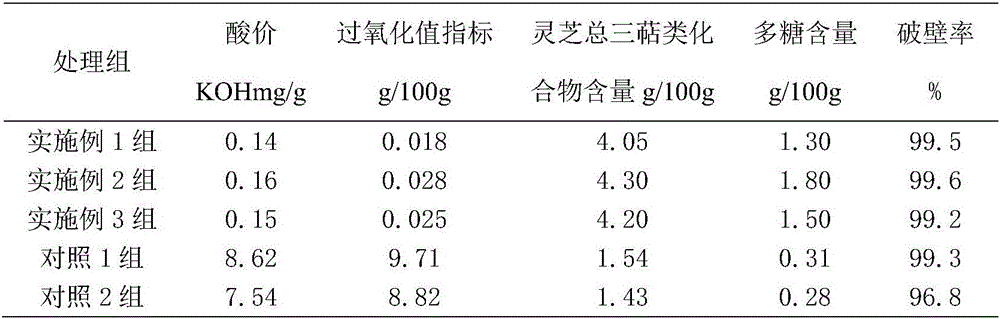

Examples

Embodiment 1

[0027] The preparation technology of ganoderma lucidum spore powder granule comprises the following steps:

[0028] (1) Raw material preparation: take the ganoderma lucidum spore powder raw material, wash with water, and remove impurities;

[0029] (2) Vacuum drying: set the vacuum degree to 0.9MPa, and the vacuum drying time to 6h, so that the moisture after vacuum drying is ≤6%;

[0030] (3) Freeze embrittlement and wall breaking: place the vacuum-dried raw materials at -18°C for embrittlement for 3 hours; then at 50°C, perform ultrasonic mixing and wall breaking; the ultrasonic frequency of the ultrasonic wave is 20 kHz , the mixing time is 5min, and the mixing speed is 40rpm.

[0031] (4) Wet granulation: Mix and granulate the broken Ganoderma lucidum spore powder and purified water at a mass ratio of 1:0.3; use a rotary granulator for granulation, the granulator speed: 55rpm, and the screen: 12 mesh.

[0032] (5) Airflow drying: set the inlet air temperature: 55°C, the...

Embodiment 2

[0035] The preparation technology of ganoderma lucidum spore powder granule comprises the following steps:

[0036] (1) Raw material preparation: take the ganoderma lucidum spore powder raw material, wash with water, and remove impurities;

[0037] (2) Vacuum drying: set the vacuum degree to 0.9MPa, and the vacuum drying time to 6h, so that the moisture after vacuum drying is ≤6%;

[0038] (3) Freeze embrittlement and wall breaking: place the vacuum-dried raw materials at -18°C for embrittlement for 5 hours; then at 60°C, perform ultrasonic mixing and wall breaking; the ultrasonic frequency of the ultrasonic wave is 20 kHz , the mixing time is 10min, and the mixing speed is 30rpm.

[0039] (4) Wet granulation: Mix and granulate the broken Ganoderma lucidum spore powder and purified water at a mass ratio of 1:0.4; use a rotary granulator for granulation, the granulator speed: 55rpm, and the screen: 12 mesh.

[0040] (5) Airflow drying: set the inlet air temperature: 55°C, th...

Embodiment 3

[0043] The preparation technology of ganoderma lucidum spore powder granule comprises the following steps:

[0044](1) Raw material preparation: take the ganoderma lucidum spore powder raw material, wash with water, and remove impurities;

[0045] (2) Vacuum drying: set the vacuum degree to 0.9MPa, and the vacuum drying time to 6h, so that the moisture after vacuum drying is ≤6%;

[0046] (3) Freeze embrittlement and wall breaking: put the vacuum-dried raw materials at -18°C for embrittlement for 4 hours; then at 55°C, perform ultrasonic mixing and wall breaking; the ultrasonic frequency of the ultrasound is 20 kHz , the mixing time is 8min, and the mixing speed is 35rpm.

[0047] (4) Wet granulation: Mix and granulate the broken Ganoderma lucidum spore powder and purified water at a mass ratio of 1:0.35; use a rotary granulator for granulation, the granulator speed: 55rpm, and the screen: 12 mesh.

[0048] (5) Airflow drying: set the inlet air temperature: 55°C, the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com