A kind of refining method of high-stability astragalus injection and astragalus injection

A technology for astragalus injection and a refining method, which is applied in the field of astragalus injection production, can solve the problems of many insoluble particles, increased unsafe factors and high production cost, achieves reduction of insoluble particle content, convenient operation by workshop workers, and low requirements for production equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

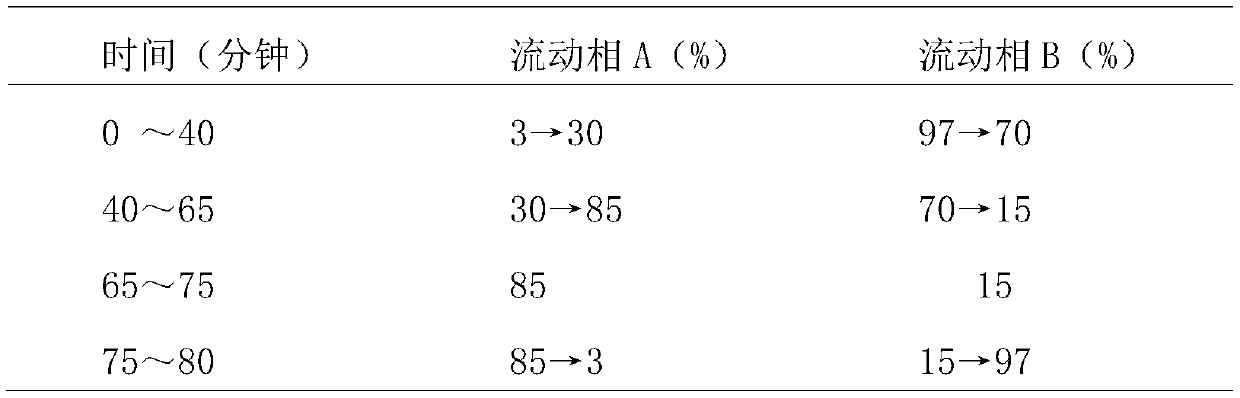

Method used

Image

Examples

Embodiment 1

[0051] Take the dry root of Astragalus membranaceus (Fisch.) Bge.var.mongholicus (Bge.) Hsiao, a leguminous plant, wash it, cut it into sections, dry it, weigh 1000g, add water to decoct 3 times, each time for 1.5 hours, filter , combined decoction. After the decoction was concentrated to 500ml, it was treated twice with ethanol precipitation. The ethanol content in the first ethanol precipitation solution was 75%, and the ethanol content in the second alcohol precipitation solution was 85%. Each time, it was refrigerated. After recovering ethanol from the alcohol solution, dilute it with water for injection to 1330ml, place it in cold storage, remove solid impurities, and obtain a water-sinking liquid, concentrate the obtained water-sinking liquid to 200ml, refrigerate it at 2-10°C for 10 hours, and filter. Adjust the pH value of the filtrate to 9.0 with 20% sodium hydroxide solution, boil for 90 minutes, and filter. Add 0.125% activated carbon to the filtrate and boil for 4...

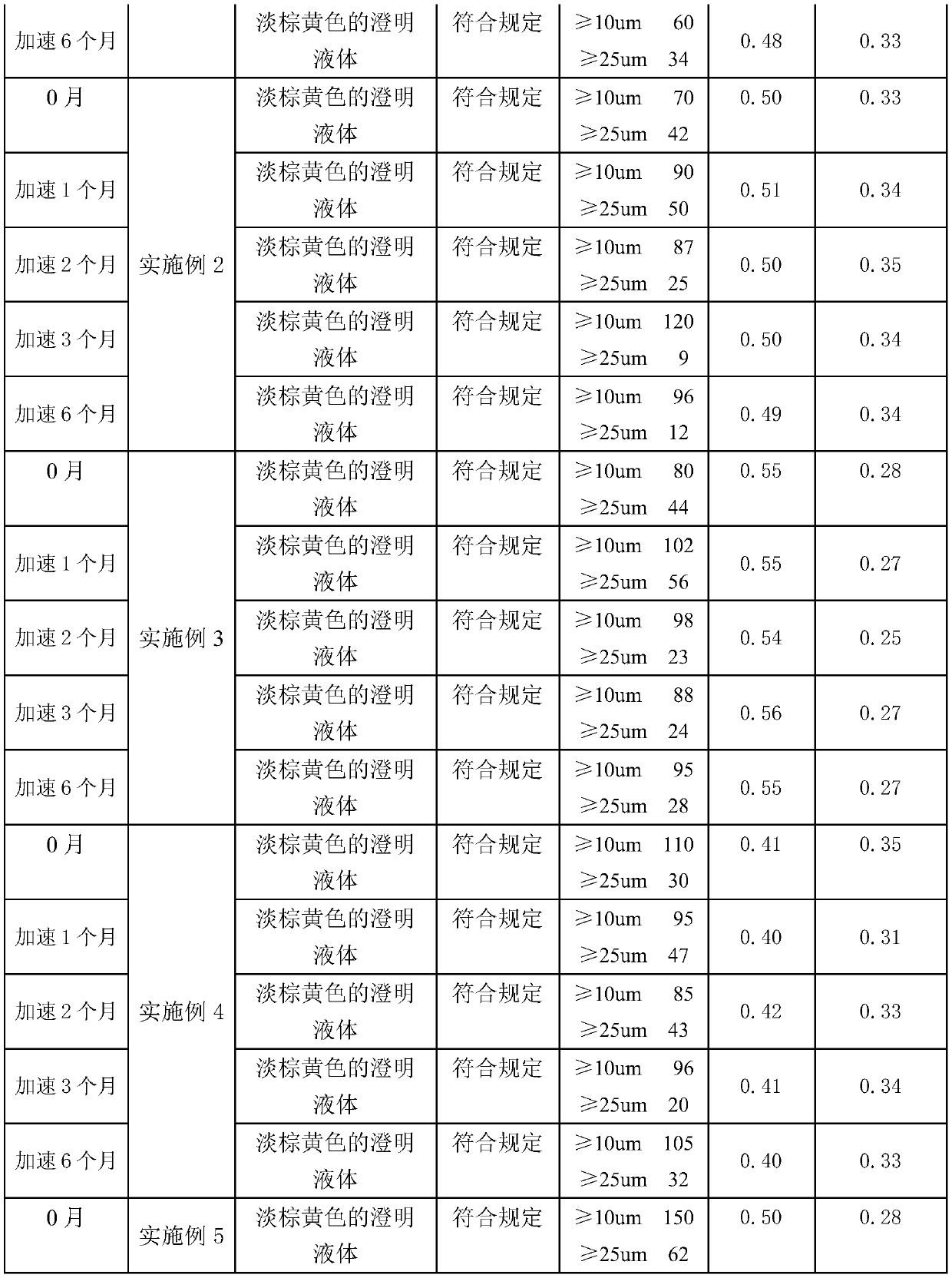

Embodiment 2

[0053] Take the dried root of the leguminous plant Astragalus membranaceus (Fisch.) Bge., wash it, cut it into sections, dry it, weigh 1000g, add water to decoct 3 times for 1.5 hours each time, filter and combine the decoction. After the decoction is concentrated to 500ml, it is processed twice with ethanol precipitation, the first time is 75%, and the second time is 85%, and each time it is refrigerated. After recovering ethanol from the alcohol solution, add water for injection to dilute to 1000ml, place in cold storage, remove solid impurities to obtain a water-sinking liquid, concentrate the obtained water-sinking liquid to 160ml, refrigerate it at 2-10°C for 8 hours, and filter. Adjust the pH value to 9.5 with 20% sodium hydroxide solution, boil for 60 minutes, and filter. Add 0.125% activated carbon to the filtrate and boil for 2 minutes, filter while it is hot, add water for injection to the full amount, filter, then adjust the pH value to 7.44 with 40% sodium hydroxid...

Embodiment 3

[0055] Take the dried roots of the leguminous plants Astragalus mongolica and Astragalus membranaceus, wash them, cut them into sections, dry them, weigh 1000g at a ratio of 1:1, add water to decoct 3 times for 1.5 hours each time, filter, and combine the decoctions. After the decoction is concentrated to 500ml, it is processed twice with ethanol precipitation, the first time is 75%, and the second time is 85%, and each time it is refrigerated. After recovering ethanol from the alcohol solution, add water for injection to dilute to 660ml of crude drug per 1ml, store in cold storage, remove solid impurities, and obtain a water-sinking liquid, concentrate the obtained water-sinking liquid to 200ml, and refrigerate it at 5-7°C for 10 hours, filter. Adjust the pH value to 9.5 with 20% sodium hydroxide solution, boil for 70 minutes, and filter. Add 0.125% activated carbon to the filtrate and boil for 5 minutes, filter while it is hot, add water for injection to the full amount, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com