Formula and preparation method of engineered bone scaffold

A technology of engineering bone and formula, applied in the field of medicine, can solve the problems of easy infection of defect lesions, large bone defect, harmful to the body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. The formula of the engineering bone scaffold listed in this embodiment is made of the following raw materials: polyvinyl alcohol powder, deionized water, and biphasic calcium phosphate powder, and the degree of alcoholysis of the polyvinyl alcohol powder is 99+%. .

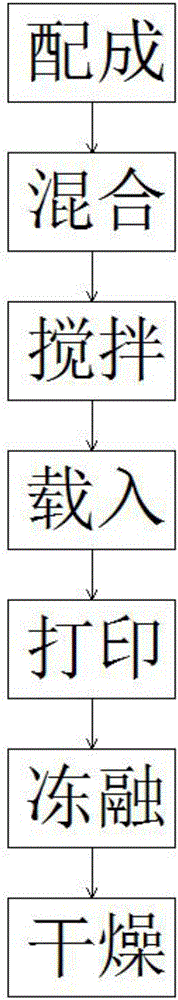

[0025] 2. The method for preparing the engineered bone scaffold according to claim 1, characterized in that: proceed as follows:

[0026] (1) Make up: first polyvinyl alcohol powder is dissolved in deionized water and is made into the polyvinyl alcohol colloid of 0.15g / ml;

[0027] (2) mixing: mixing polyvinyl alcohol colloid and biphasic calcium phosphate powder in (1);

[0028] (3) Stirring: Stir the compound in (2) evenly to obtain a mixed tissue of biphasic calcium phosphate and polyvinyl alcohol paste;

[0029] (4) Loading: load the three-dimensional file of the patient's bone defect model into the biomaterial printer;

[0030] (5) Printing: Pour the mixed tissue of biphasic calcium phosphate and...

Embodiment 2

[0039] 1. The formula of the engineering bone scaffold listed in this embodiment is made of the following raw materials: polyvinyl alcohol powder, deionized water, and biphasic calcium phosphate powder, and the degree of alcoholysis of the polyvinyl alcohol powder is 99+%. .

[0040] 2. The method for preparing the engineered bone scaffold according to claim 1, characterized in that: proceed as follows:

[0041] (1) Make up: first polyvinyl alcohol powder is dissolved in deionized water and is made into the polyvinyl alcohol colloid of 0.15g / ml;

[0042] (2) mixing: mixing polyvinyl alcohol colloid and biphasic calcium phosphate powder in (1);

[0043](3) Stirring: Stir the compound in (2) evenly to obtain a mixed tissue of biphasic calcium phosphate and polyvinyl alcohol paste;

[0044] (4) Loading: load the three-dimensional file of the patient's bone defect model into the biomaterial printer;

[0045] (5) Printing: Pour the mixed tissue of biphasic calcium phosphate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com