Molecularly imprinted columns for the simultaneous separation of clenbuterol, albuterol, and ractopamine

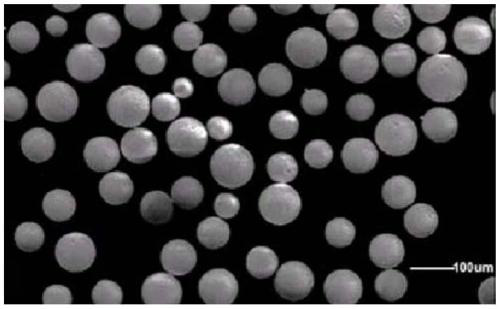

A technology of molecularly imprinted columns and ractopamine, which is applied in separation methods, solid adsorbent liquid separation, analysis materials, etc., to achieve good separation and enrichment effects and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1 Preparation of Clenbuterol Molecularly Imprinted Polymer

[0054] 1. Weigh 2g of clenbuterol into 20mL of water, add 2mL of 0.1moL / L hydrochloric acid to fully dissolve it; use 1moL / L of NaOH to adjust the pH to above 12; extract three times with an equal volume of chloroform, and extract After dehydration with 3 g of anhydrous sodium sulfate, and rotary vacuum drying at 50°C, white or nearly white clenbuterol crystalline powder was obtained.

[0055] 2. Add 100mL of 4% polyvinyl alcohol 1788 into the four-neck flask, stir at 400r / min while blowing nitrogen for 10min.

[0056] 3. In another container, mix 0.8mL DEAEM, 5.0mL EGDMA, 10.0mL octanol, 0.5g clenbuterol from which the inhibitor has been removed, and ultrasonically mix for 20min, then add 120mg AIBN, 5mL chloroform and continue ultrasonication for 5min , Add ice cubes during sonication to keep the temperature low. Maintain stirring speed to ensure good monomer dispersion.

[0057] 4. Continuous nit...

Embodiment 2

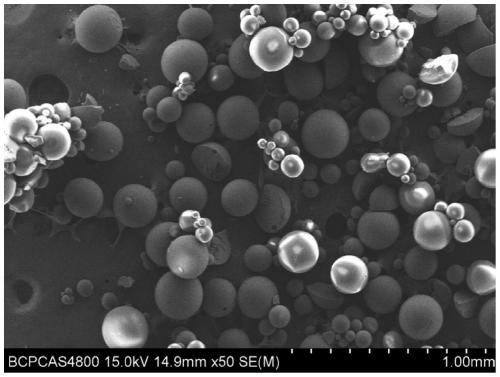

[0062] Example 2 Preparation of Salbutamol Molecularly Imprinted Polymer

[0063] 1. Add 100mL of 4% polyvinyl alcohol 1788 (PVA 1788) into a four-neck flask, stir at 400r / min while blowing nitrogen for 10min.

[0064] 2. In another container, 0.8mL MAA, 5.0mL EGDMA, 10.0mL octanol, 0.3g albuterol, which have been removed from the polymerization inhibitor, were mixed ultrasonically for 20min, then added 120mg AIBN, 5mL chloroform and continued ultrasonication for 5min. Add ice cubes and keep cold. Maintain stirring speed to ensure good monomer dispersion.

[0065] 3. Continuous nitrogen flow, 70°C, react for 24h.

[0066] 4. After the polymerization reaction, the obtained polymer microspheres were filtered out, rinsed with water three times, poured into a 200mL beaker, and stirred with deionized water at 80°C for 60min.

[0067] 5. Wash three times with 50 mL of methanol and two times with 50 mL of acetone to remove organic matter such as swelling agent and residual organic...

Embodiment 3

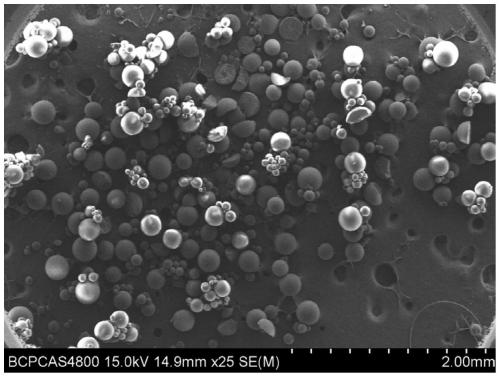

[0070] Example 3 Preparation of Ractopamine Molecularly Imprinted Polymer

[0071] 1. Add 100mL of 4% polyvinyl alcohol 1788 (PVA 1788) into a four-neck flask, stir at 400r / min while blowing nitrogen for 10min.

[0072] 2. In another container, mix 0.8mL MAA, 5.0mL EGDMA, 10.0mL octanol, 0.6g ractopamine, which have been removed from the polymerization inhibitor, for 20 minutes by ultrasonication, then add 120mg AIBN, 5mL chloroform and continue ultrasonication for 5 minutes. Add ice cubes and keep cold. Maintain stirring speed to ensure good monomer dispersion.

[0073] 3. Continuous nitrogen flow, 70°C, react for 24h.

[0074] 4. After the polymerization reaction, the obtained polymer microspheres were filtered out, rinsed with water three times, poured into a 200mL beaker, and stirred with deionized water at 80°C for 60min.

[0075] 5. Wash three times with 50 mL of methanol and two times with 50 mL of acetone to remove organic matter such as swelling agent and residual ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com