Flue gas treatment method for realizing desulphurization and denitrification simultaneously by using lanthanum-cerium oxide-loaded titanium dioxide nanotube array for catalytic reduction

A nanotube array, titanium dioxide technology, applied in the field of environmental protection science, can solve the problems of difficult separation and recovery of subsidiary products, difficult catalyst preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation of catalyst of the present invention:

[0026] First, take a certain amount of tetrabutyl titanate and 40ml of absolute ethanol and put them in a beaker, add a certain amount of glacial acetic acid, which is called A liquid, and stir the A liquid on a magnetic stirrer until it is evenly mixed. Take another beaker, add 20ml of absolute ethanol, 5ml of distilled water and proportionately weighed crystals of lanthanum nitrate hexahydrate and cerium nitrate hexahydrate, stir and dissolve in the beaker, which is called liquid B. Pour liquid B into an acid burette, add it drop by drop to vigorously stirred liquid A at a uniform and slow speed, age at 30-80°C for 6-72h to form a gel, and then dry it in an oven at 105°C for 12h , and then roasted in a muffle furnace at 400-800°C for 1-9h to obtain catalyst particles, grind and sieve, and select 20-40 mesh particles for later use.

Embodiment 1

[0027] Example 1: 1La 2 o 3 -3CeO 2 -4TiO 2 Catalytic reduction and simultaneous desulfurization and denitrification

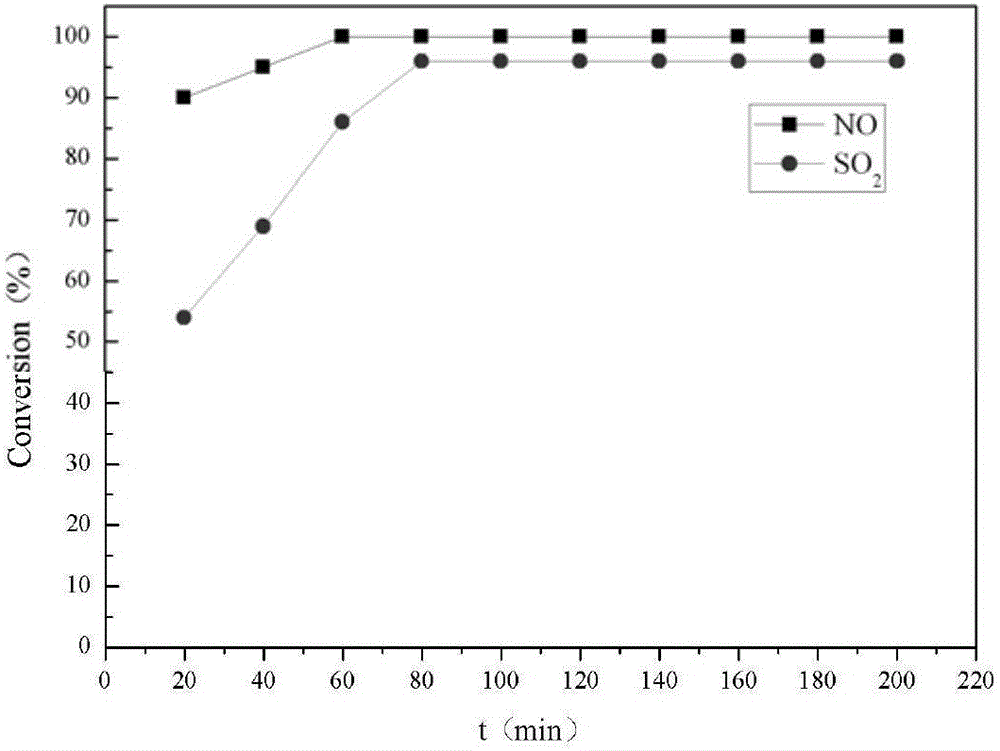

[0028] Load 10g of catalyst 1La in the reactor of the tubular resistance furnace 2 o 3 -3CeO 2 -4TiO 2 10 minutes with nitrogen gas first, then start to heat up, and nitrogen gas at the same time, when the temperature rises to 500°C, a mixed gas (10% by volume of nitrogen monoxide, 50% by volume of carbon monoxide, 20% by volume of sulfur dioxide, and the rest Nitrogen), the space velocity is 7000mL / (g h), the aeration time is 120 minutes, the exhaust gas is detected by the flue gas analyzer after passing through the condensation tank, and then the nitrogen is recovered after passing through the lime water, and the elemental sulfur and carbon are calculated by gravimetric method . The denitrification efficiency is 100%, the desulfurization efficiency is 97.1%; the elemental sulfur recovery rate is above 97.3%, and the N 2 The recovery rate is 98.4%, i...

Embodiment 2

[0029] Example 2: 2La 2 o 3 -5CeO 2 -7TiO 2 Catalytic reduction and simultaneous desulfurization and denitrification

[0030] Load 10g of catalyst 2La in the reactor of the tubular resistance furnace 2 o 3 -5CeO 2 -7TiO 2First pass nitrogen for 10 minutes, then start to heat up, and feed nitrogen at the same time, when the temperature rises to 500°C, feed mixed gas (10% by volume of sulfur dioxide, 5% by volume of nitrogen monoxide, 5% by volume of nitrogen dioxide , the volume percentage of carbon monoxide is 35%, and the rest is nitrogen), the space velocity is 10000mL / (g h), the aeration time is 120 minutes, the exhaust gas is detected by the flue gas analyzer after passing through the condensation tank, and then the nitrogen is recovered after passing through the lime water , elemental sulfur and carbon are calculated by gravimetric method. The denitrification efficiency is 100%, the desulfurization efficiency is 97.0%, the elemental sulfur recovery rate is 97.1%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap