Nano-sized high-flux PVDF (polyvinylidene fluoride) plate ultrafiltration membrane as well as screening method and preparation method thereof

A screening method, ultrafiltration membrane technology, applied in ultrafiltration, chemical instruments and methods, membranes, etc., can solve the problems of not being able to significantly improve the actual flux and pore size distribution of the membrane, complex process flow, improper maintenance and management, etc., to achieve optimization Analysis of membrane performance, simplified screening process, and the effect of accurate drug dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The present embodiment provides a screening method of nano-type high-throughput PVDF flat ultrafiltration membrane, which is carried out in the following steps:

[0048] 1) The influence of variables such as membrane material type, added membrane material concentration, porogen concentration and membrane thickness on membrane performance was investigated by orthogonal experiment method, and the key influencing factors of membrane performance were clarified as follows: membrane material type, dosage Membrane material concentration, porogen concentration and membrane thickness. The design of the orthogonal table header is as follows:

[0049]

[0050] Orthogonal experiment results are as follows:

[0051]

[0052]

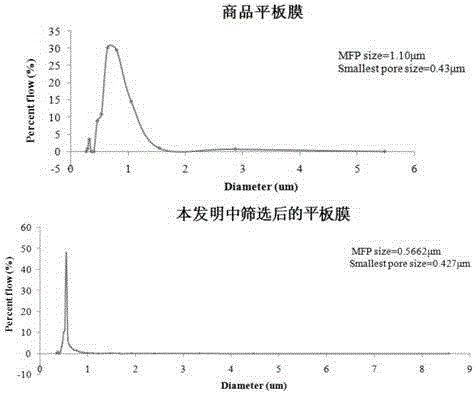

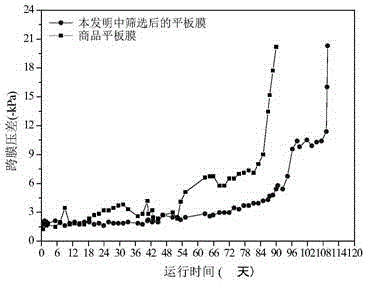

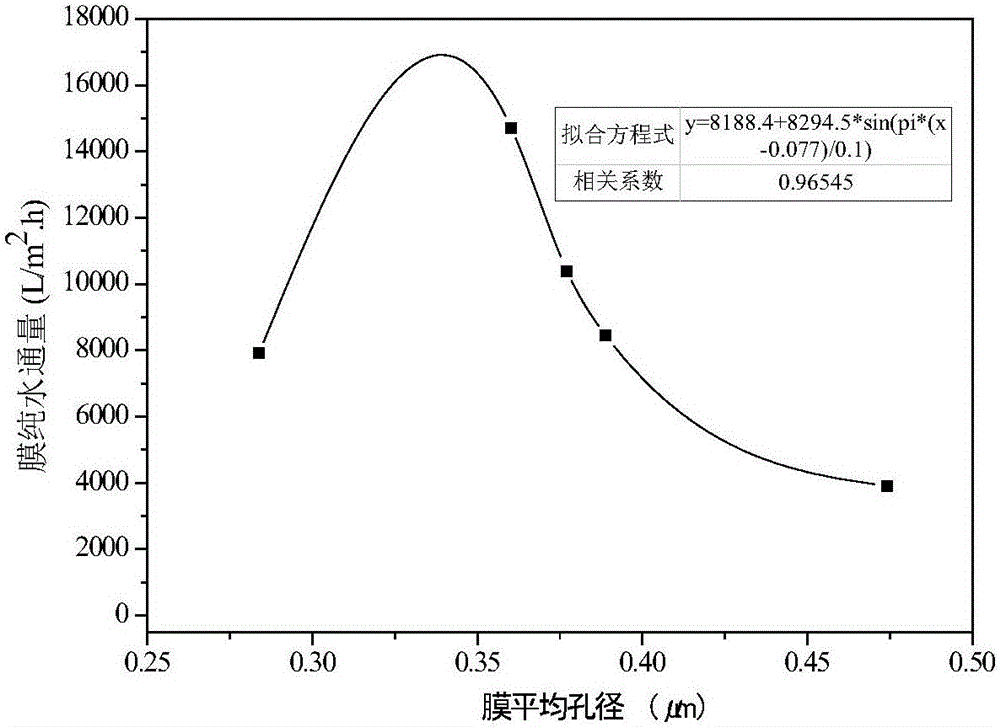

[0053] 2) Using the single factor variable method experiment, screening polyvinylidene fluoride membrane materials and porogens from different manufacturers, and determined that the optimal polyvinylidene fluoride membrane material has a weight-avera...

Embodiment 2

[0060] Other conditions are the same as in Example 1, and the weight average molecular weight of the polyvinylidene fluoride membrane material is adjusted to 550,000.

[0061] According to the calculation results, the weight ratio of polyvinylidene fluoride film material, nanometer material, polyvinylpyrrolidone, polyethylene glycol and N-methylpyrrolidone is 12:1:5:3:79. The measured pure water flux of the PVDF flat membrane is 25000LMH, the actual critical flux of the membrane is 56LMH, the membrane contact angle is 70°, and the membrane pore size ranges from 0.57-0.69μm.

Embodiment 3

[0063] The present embodiment provides a method for preparing a nano-type high-flux PVDF flat ultrafiltration membrane, comprising the following steps:

[0064] 1) Divide the solvent into two parts, get 4g nano TiO 2 Dissolve in 94g of N,N-dimethylacetamide (DMAC), and ultrasonically disperse for 1.5h with a digitally controlled ultrasonic disperser with an ultrasonic power of 240W. Then the casting solution is prepared according to the weight ratio of polyvinylidene fluoride: solvent: porogen: nanometer material = 15:75:8:2.

[0065] 2) The porogen is composed of polyvinylpyrrolidone (molecular weight: 40,000) and polyethylene glycol with a weight ratio of 1:1. The porogen is dissolved in the remaining solvent at a dissolution temperature of 70°C and a dissolution time of 30 minutes.

[0066] 3) The ultrasonically dispersed nanomaterials and polyvinylidene fluoride (weight average molecular weight: 1 million) are sequentially dissolved in the remaining solvent and mixed even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Pure water flux | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com