Method and device for treating coking wastewater and producing hydrogen gas by microbial electrolysis cell

A technology for microbial electrolysis cells and coking wastewater, which is applied in biological water/sewage treatment, biochemical fuel cells, chemical instruments and methods, etc., can solve the problems of complicated operation, long time-consuming coking wastewater, etc., and achieves low consumption cost, low investment, Good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

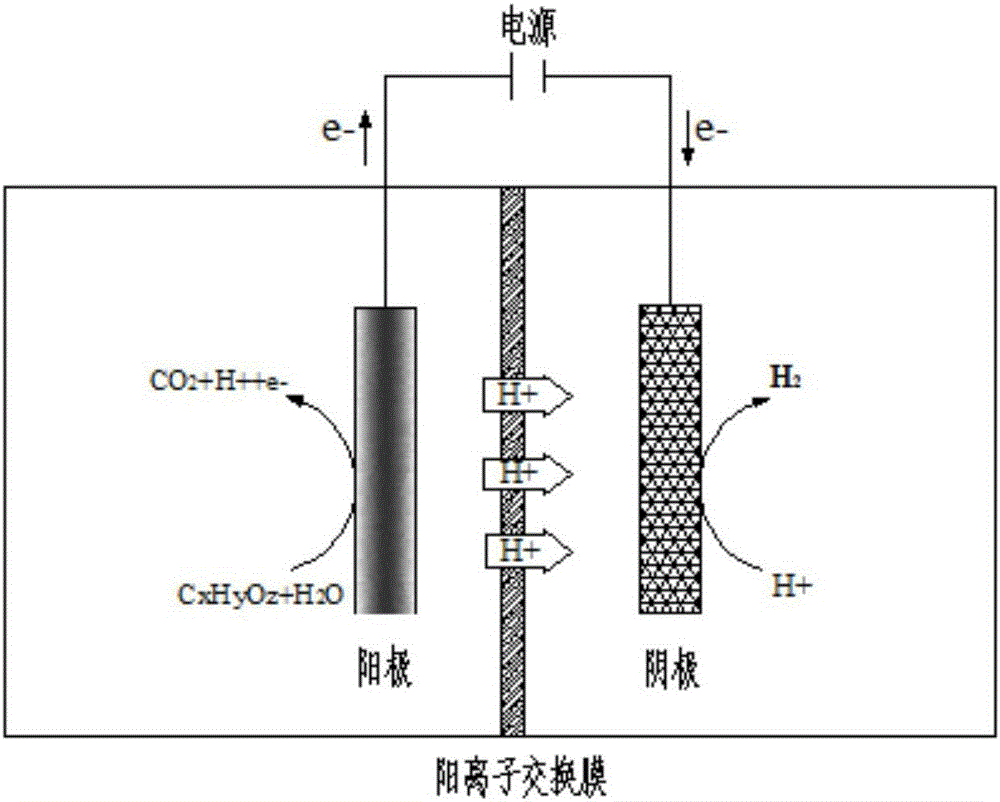

[0062] figure 1 Schematic diagram of a microbial electrolytic cell. The anode microorganisms oxidize the organic matter in the coking wastewater to produce hydrogen ions and electrons. The generated electrons are transmitted to the anode of the microbial electrolysis cell through the mediator or the microbial respiratory chain, and are transmitted to the cathode from the external circuit through the wire. The hydrogen ions pass through the proton The exchange membrane is transferred to the cathode, and the hydrogen ions in the cathode compartment accept electrons under a certain voltage to produce hydrogen.

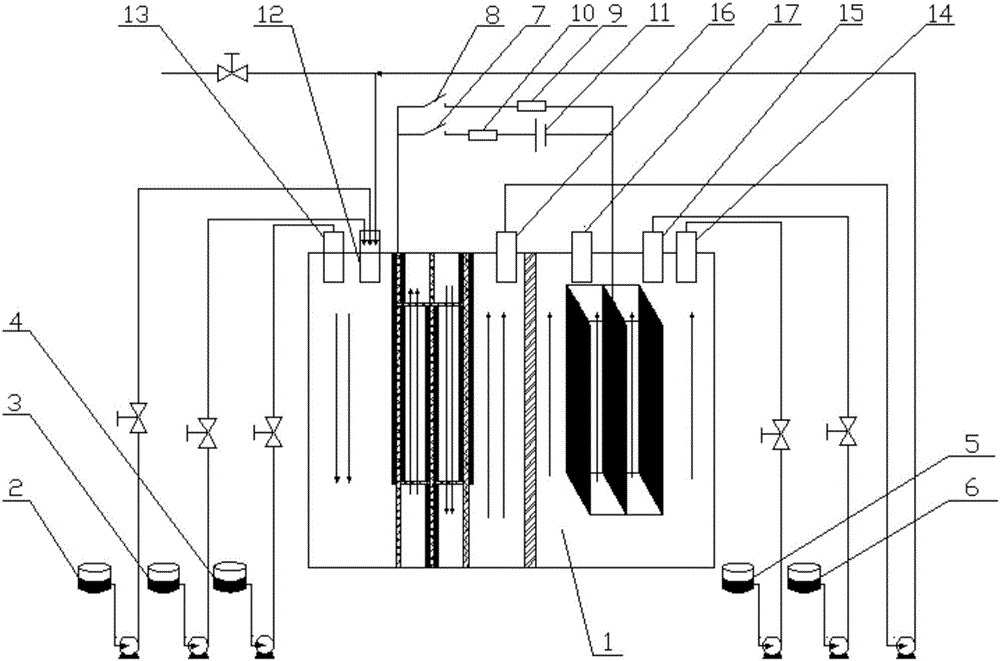

[0063] Such as figure 2 As shown, a device for treating coking wastewater and producing hydrogen using a microbial electrolytic cell in this embodiment includes an electrolytic cell 1, which also includes a coking wastewater storage tank 2, tap water storage tank 3, anolyte storage tank 4, catholyte Storage tank 5, cathode waste liquid storage tank 6, two switches 7, 8...

Embodiment 2

[0103] In this embodiment, a device for treating coking wastewater and producing hydrogen using a microbial electrolytic cell is the same as that in Embodiment 1.

[0104] A method for treating coking wastewater and producing hydrogen by utilizing the above-mentioned microbial electrolytic cell, comprising the following steps:

[0105] 1) Activation of coking wastewater bacteria

[0106] Take the bacterial sludge from the aerobic tank and the anaerobic tank of the coking plant and mix it according to the mass ratio of 1:1.2, and store the mixed bacterial sludge in the freezer for later use; when using it, first put the mixed bacterial sludge in a 6°C freezer After thawing, the microbial fuel cell anolyte was added to the mixed bacterial sludge until the mixed bacterial sludge was submerged, and activated at 30°C for 96 hours;

[0107] 2) Treatment of anode electrode carbon felt

[0108] Its processing steps are as follows:

[0109] ①Rinse with distilled water; ②Soak in 0.5mol...

Embodiment 3

[0137] In this embodiment, a device for treating coking wastewater and producing hydrogen using a microbial electrolytic cell is the same as that in Embodiment 1.

[0138] A method for synchronously producing hydrogen from coking wastewater by using the above-mentioned microbial electrolytic cell, comprising the following steps:

[0139] 1) Activation of coking wastewater bacteria

[0140] Take the bacterial sludge from the aerobic tank and anaerobic tank of the coking plant and mix it at a mass ratio of 1:1.5, and store the mixed bacterial sludge in the freezer for later use; when using it, first place the mixed bacterial sludge in a freezer at 8°C After thawing, the microbial fuel cell anolyte was added to the mixed bacterial sludge until the mixed bacterial sludge was submerged, and activated at 35°C for 120 hours;

[0141] 2) Treatment of anode electrode carbon felt

[0142] Its processing steps are as follows:

[0143]①Rinse with distilled water; ②Soak in 0.5mol / L HCl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com