Modified nano chloroapatite and its preparation method

A chloroapatite and nano-technology, applied in the field of modified nano-chloroapatite and its preparation, can solve the problems of unavoidable water body eutrophication, poor repairing effect of heavy metals, water body eutrophication and the like, and reduce water body eutrophication. The risk of eutrophication, the effect of improving stabilization, and the effect of inhibiting eutrophication in water bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

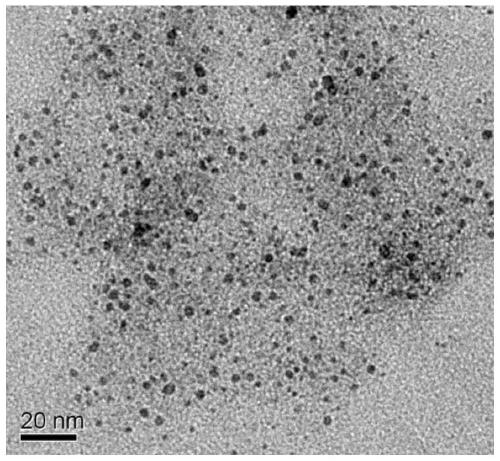

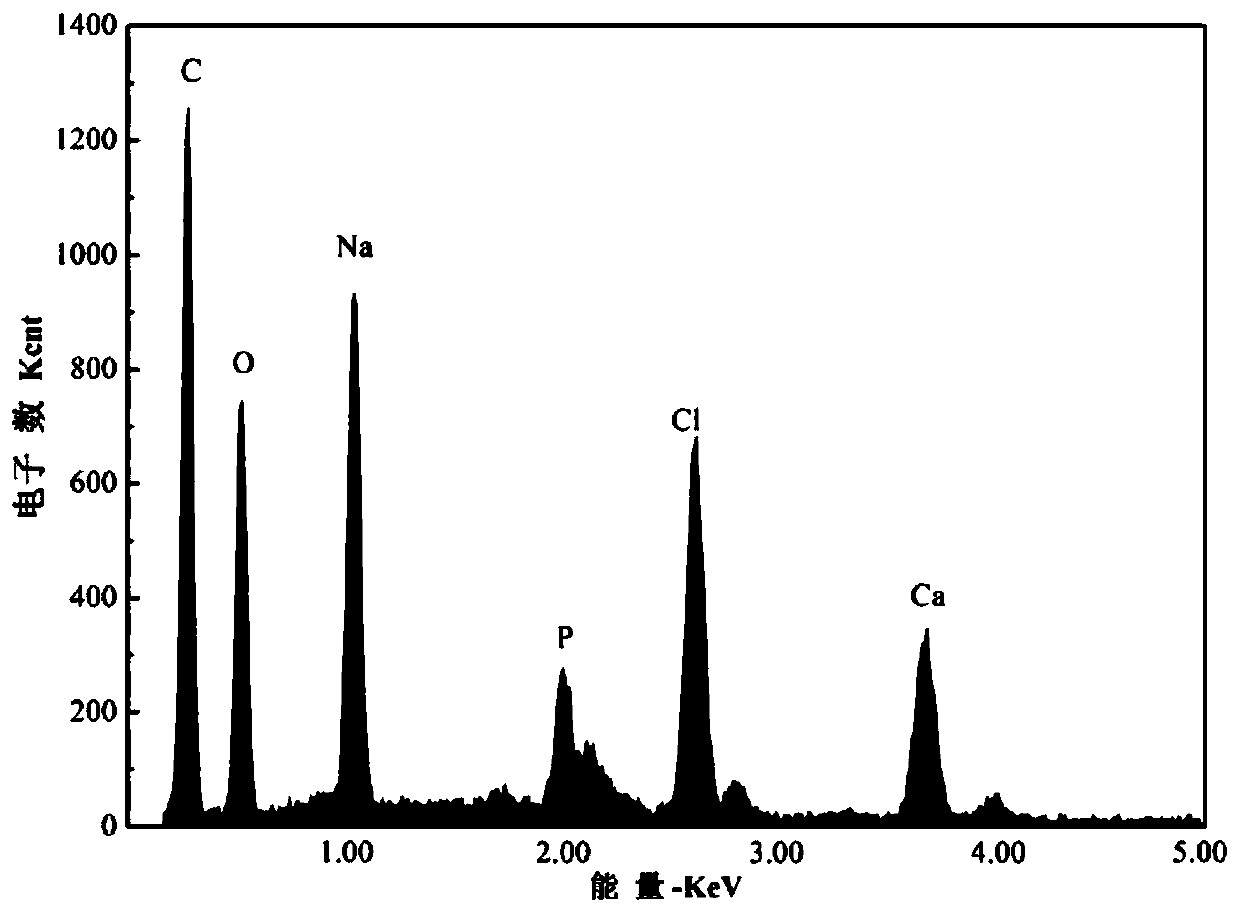

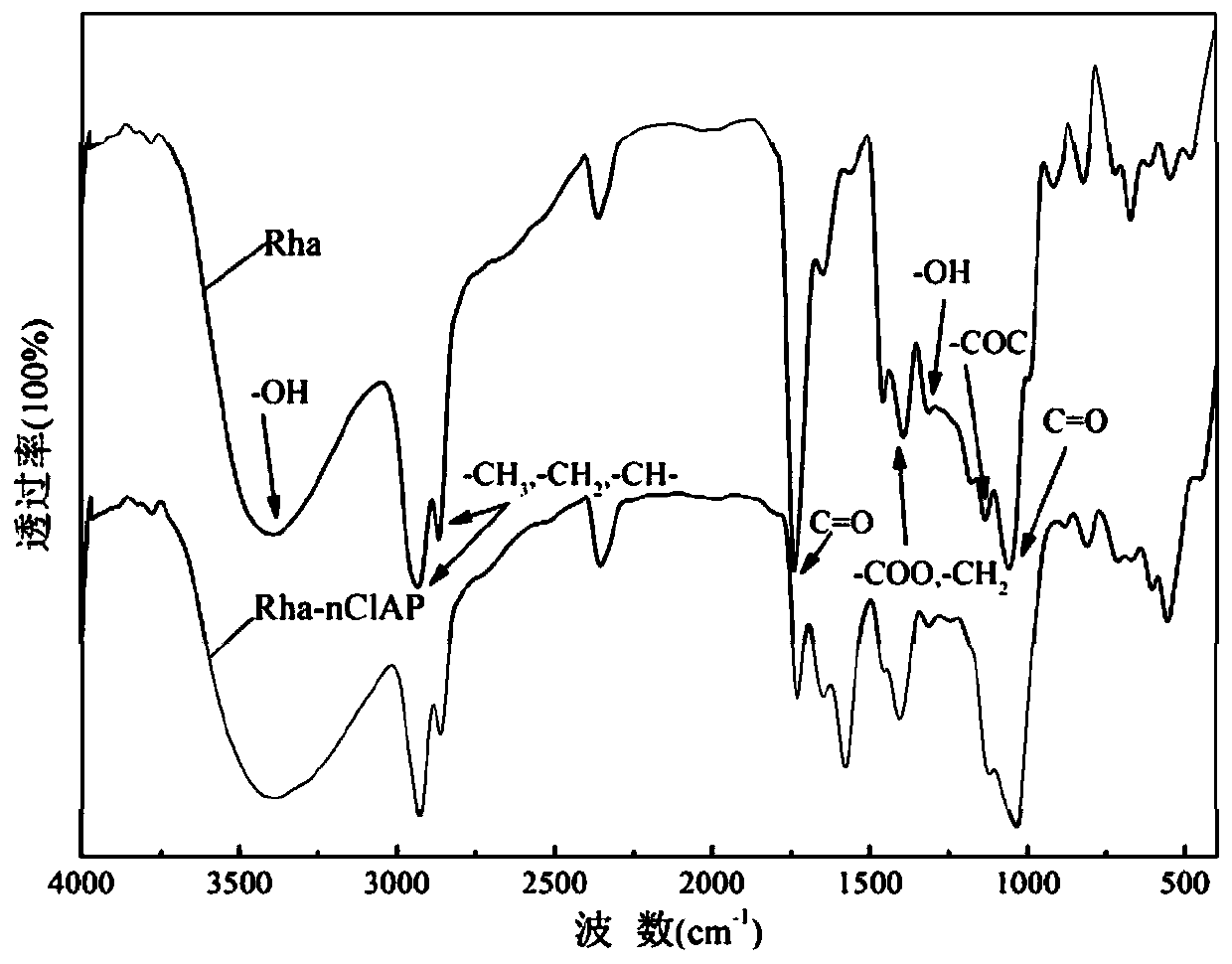

[0032] A modified nano-chloroapatite (Rha-nClAP) of the present invention, the modified nano-chloroapatite is composed of rhamnolipid (Rha) and nano-chloroapatite, the rhamnolipid is modified in nano On the surface of chloroapatite, the mass ratio of nano-chloroapatite to rhamnolipid is 46.498:1.

[0033] In this embodiment, the particle size of the modified nano-chloroapatite is 2 nm to 5 nm.

[0034] A method for preparing the modified nano-chloroapatite of this embodiment described above includes the following steps:

[0035] (1) Preparation of rhamnolipid solution: Weigh 30 mg of rhamnolipid (the purity of the rhamnolipid is 90%, the critical micelle concentration is 25mg / L, and the mono-rhamnolipid and di-rhamnose The mass ratio of fat is 2:1) Dissolve in 800mL ultrapure water, place it in ultrasonic for ten minutes and adjust the pH of the solution to 8.4 with 0.1M sodium hydroxide to make it completely dissolve, add appropriate amount of ultrapure water to dissolve Transfer ...

Embodiment 2

[0041] A modified nano-chloroapatite (Rha-nClAP) of the present invention, the modified nano-chloroapatite is composed of rhamnolipid (Rha) and nano-chloroapatite, the rhamnolipid is modified in nano On the surface of chloroapatite, the mass ratio of nano-chloroapatite to rhamnolipid is 27.8988:1.

[0042] In this embodiment, the particle size of the modified nano-chloroapatite particles is 2 nm to 5 nm.

[0043] A method for preparing the modified nano-chloroapatite of this embodiment described above includes the following steps:

[0044] (1) Preparation of rhamnolipid solution: Weigh 50mg of rhamnolipid (the purity of the rhamnolipid is 90%, the critical micelle concentration is 25mg / L, and the mono-rhamnolipid and di-rhamnose The mass ratio of fat is 2:1) Dissolve in 800mL ultrapure water, place it in ultrasonic for ten minutes and adjust the pH of the solution to 8.4 with 0.1M sodium hydroxide to make it completely dissolve, add appropriate amount of ultrapure water to dissolve ...

Embodiment 3

[0051] A modified nano-chloroapatite (Rha-nClAP) of the present invention, the modified nano-chloroapatite is composed of rhamnolipid (Rha) and nano-chloroapatite, and the rhamnolipid is modified in nano On the surface of chloroapatite, the mass ratio of nano-chloroapatite to rhamnolipid is 19.9277:1.

[0052] In this embodiment, the particle size of the modified nano-chloroapatite is 2 nm to 5 nm.

[0053] A method for preparing the modified nano-chloroapatite of this embodiment described above includes the following steps:

[0054] (1) Preparation of rhamnolipid solution: Weigh 70 mg of rhamnolipid (the purity of the rhamnolipid is 90%, the critical micelle concentration is 25mg / L, and the mono-rhamnolipid and di-rhamnose The mass ratio of fat is 2:1) Dissolve in 800mL ultrapure water, place it in ultrasonic for ten minutes and adjust the pH value of the solution to 8.4 with 0.1M sodium hydroxide to make it completely dissolve, add appropriate amount of ultrapure water to dissolve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com