Preparation method of ciprofloxacin lactate

A technology of ciprofloxacin lactate and ciprofloxacin, which is applied in the direction of organic chemistry, can solve the problems of prolonging the production cost of the process flow, and achieve the effects of shortening the production cycle, simplifying the process flow, and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

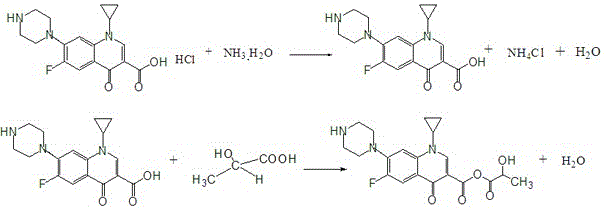

Image

Examples

Embodiment 1

[0031] A preparation method of ciprofloxacin lactate, comprising the following steps:

[0032] 1) Put 10g of ciprofloxacin hydrochloride and 100g of purified water into the flask, raise the temperature to 53°C, and stir to dissolve;

[0033] 2) Under the condition of 55°C, add about 0.19g of ammonia water with a concentration of 7wt% to the solution obtained in step 1), crystals will be precipitated in the solution, and the crystals will be grown for 25 minutes; then continue to drop ammonia water to the pH of the solution 6.8, after cooling the solution to 30°C, grow the crystal for 4 hours; control the dripping speed of ammonia water so that the ammonia solution is added dropwise for 30 minutes until the pH value of the solution reaches the requirement;

[0034] 3) The crystals obtained in step 2) were collected by filtration, washed three times with 50g of purified water, and then washed twice with 20g of ethanol with a volume concentration of 95%, and then vacuumed the cry...

Embodiment 2

[0039] A preparation method of ciprofloxacin lactate, comprising the following steps:

[0040] 1) Put 10g of ciprofloxacin hydrochloride and 100g of purified water into the flask, raise the temperature to 55°C, and stir to dissolve;

[0041] 2) Under the condition of 55°C, add sodium hydroxide solution with a concentration of 4wt% to the solution obtained in step 1) dropwise. When crystals are precipitated in the solution, grow the crystal for 30 minutes; then continue to add sodium hydroxide solution dropwise to The pH in the solution is 7.0. After cooling the solution to 25°C, grow the crystal for 4 hours; control the dropping rate of the sodium hydroxide solution so that the sodium hydroxide solution is added dropwise for 30 minutes until the pH of the solution reaches the requirement;

[0042] 3) The crystals obtained in step 2) were collected by filtration, washed three times with 50g purified water, and then washed twice with 20g ethanol with a volume concentration of 95...

Embodiment 3

[0046] A preparation method of ciprofloxacin lactate, comprising the following steps:

[0047] 1) Put 10g of ciprofloxacin hydrochloride and 120g of purified water into the flask, raise the temperature to 90°C, and stir to dissolve;

[0048] 2) Lower the temperature of the solution obtained in step 1) to 55°C, add dropwise ammonia water with a concentration of 7wt% until crystals are precipitated in the solution, and grow the crystal for 30 minutes; then continue to drop ammonia water until the pH of the solution is 7.0. After cooling down to 30°C, grow the crystal for 4 hours; control the dripping rate of ammonia water so that the ammonia water is added dropwise for 30 minutes until the pH value of the solution reaches the requirement;

[0049] 3) The crystals obtained in step 2) were collected by filtration, washed three times with 50g of purified water, and then washed twice with 20g of ethanol with a volume concentration of 95%, and then vacuumed the crystals at 60°C and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com