Method for preparing hard sandwich cross-linked PVC foam material

A foaming material and sandwich technology, which is applied in the field of foaming material preparation, can solve problems such as limiting process parameters, increasing process control difficulty, affecting acidity, etc., and achieves high toughness, excellent mechanical strength, and improved foaming efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for preparing a rigid sandwich cross-linked PVC foam material, adopts the following steps:

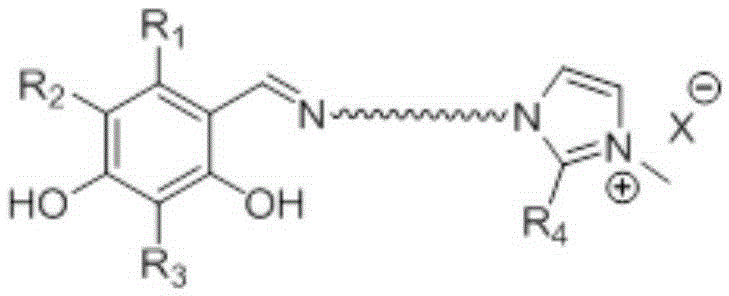

[0050] (1) Weigh raw materials by weight: 100 parts of polyvinyl chloride resin, 5 parts of chlorinated polyethylene, 80 parts of isocyanate (MDI), 2 parts of this ionic liquid surfactant, 10 parts of blowing agent, 10 parts of acid anhydride , 3 parts of stabilizer, and AIBN as the initiator, wherein the isocyanate used is 2,2'-dimethyl-3,3',5,5'-triphenylmethane tetraisocyanate, ionic liquid surfactant for the following molecular structure:

[0051]

[0052] Among them, R 1 , R 2 , R 3 , R 4 Respectively H, OH, SH, Me, X is Br, blowing agent is cyclohexane, acid anhydride is maleic acid rod, polysebacic anhydride, a kind of in hexahydrophthalic anhydride, what adopted in the present embodiment is maleic acid rod to acid anhydride. The stabilizer is one of metal stabilizers such as epoxidized oil such as soybean oil, linseed oil, magnesium oxide, calcium-zinc ...

Embodiment 2

[0059] A method for preparing a rigid sandwich cross-linked PVC foam material, adopts the following steps:

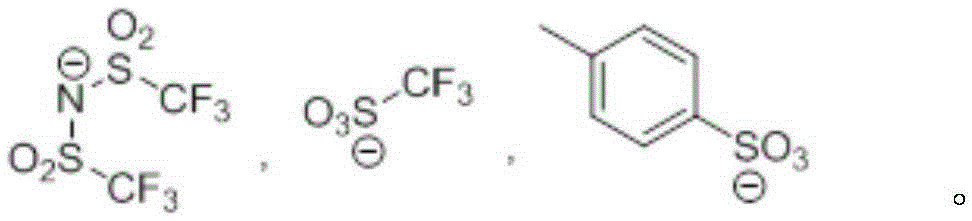

[0060] (1) Raw material preparation: Weigh polyvinyl chloride resin, chlorinated polyethylene, isocyanate, ionic liquid surfactant, foaming agent, acid anhydride, stabilizer agent as a raw material, and azobisisobutyronitrile as an initiator, wherein the isocyanate used is 2,4-toluene diisocyanate, and the ionic liquid surfactant has the following molecular structure:

[0061]

[0062] Among them, R 1 , R 2 , R 3 , R 4 Both are H, X is I, the blowing agent is 2,2'-azobisisobutyronitrile, the acid anhydride is polysebacic anhydride, and the stabilizer is magnesium oxide;

[0063] (2) Pre-stirring and heating: Put all the components in the formula into the kneader and mix them evenly. Components do not react chemically;

[0064] (3) Plastic molding: Pour the obtained mixture into the mold, close the mold, pressurize and heat, and the heating temperature is 100°C....

Embodiment 3

[0068] A method for preparing a rigid sandwich cross-linked PVC foam material, adopts the following steps:

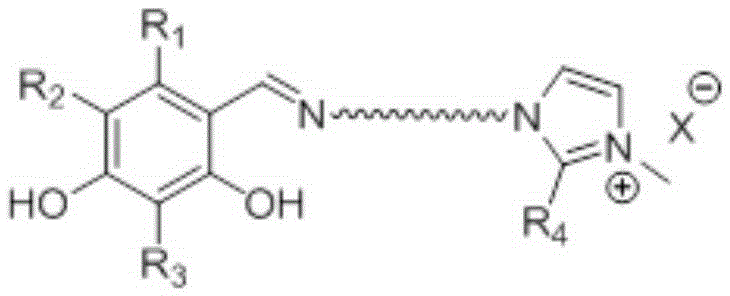

[0069] (1) Material preparation: weigh polyvinyl chloride resin, chlorinated polyethylene, isocyanate, ionic liquid surfactant, foaming agent, acid anhydride, stabilizer agent as a raw material, and azobisisobutyronitrile as an initiator, wherein the isocyanate used is 4,4'-methylenebis(phenylisocyanate), and the ionic liquid surfactant has the following molecular structure:

[0070]

[0071] Among them, R 1 , R 2 , R 3 , R 4 Both are H, X is PF 6 , the foaming agent is 2,2'-azobisisobutyronitrile, the acid anhydride is hexahydrophthalic anhydride, and the stabilizer is calcium-zinc complex agent;

[0072] (2) Pre-stirring and heating: Put all the components in the formula into the kneader and mix them evenly. Components do not react chemically;

[0073] (3) Plastic molding: Pour the obtained mixture into the mold, pressurize and heat the mold, and the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com