Environment-friendly anticorrosion quick-drying type primer-topcoat integrated air-dry paint and preparation method thereof

A quick-drying, self-drying paint technology, applied in the direction of anti-corrosion coatings, chemical instruments and methods, drier, etc., can solve the problems of poor durability, slow self-drying, etc., to improve quick-drying performance, high work efficiency, excellent water resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

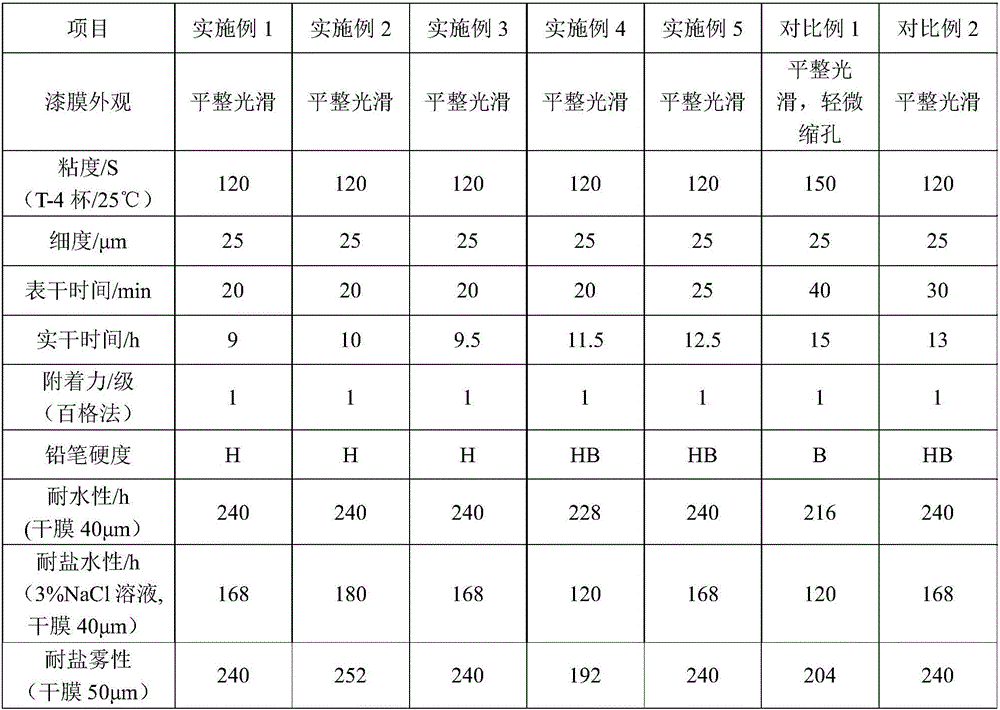

Examples

Embodiment 1

[0033] An environment-friendly anti-corrosion and quick-drying self-drying paint with bottom and surface in one. The raw material composition is calculated by mass parts: 20 parts of acrylic modified epoxy ester resin, 25 parts of styrene modified acrylic resin, calcium manganese naphthenate catalyst 2 parts of dry agent, 4 parts of organically modified zinc phosphate hydrate containing calcium strontium aluminum, 3 parts of iron oxide red, 2 parts of mica powder, 8 parts of sunfast red powder, 15 parts of modified superfine precipitated barium sulfate, anti-flash 1.5 parts of rust agent, 0.5 parts of dodecyl alcohol ester, 1 part of dipropylene glycol methyl ether, 0.3 parts of dispersant, 0.2 parts of defoamer, 0.2 parts of wetting agent, 0.2 parts of leveling agent, 0.4 parts of thickener, AMP 1 part of -95 neutralizer, 15 parts of deionized water, among them, the calcium-manganese naphthenate composite drier is calcium naphthenate, manganese naphthenate, and isobutanol in a...

Embodiment 2

[0035] An environment-friendly anti-corrosion and quick-drying self-drying paint with bottom and surface in one. The raw materials are composed by mass parts: 25 parts of acrylic modified epoxy ester resin, 30 parts of styrene modified acrylic resin, calcium manganese naphthenate catalyst 2.5 parts of dry agent, 5 parts of organically modified zinc phosphate hydrate containing calcium strontium aluminum, 4 parts of iron oxide red, 3 parts of mica powder, 8 parts of sunfast red powder, 20 parts of modified superfine precipitated barium sulfate, anti-flash 2 parts of rust agent, 0.8 parts of dodecyl alcohol ester, 1.2 parts of dipropylene glycol methyl ether, 0.4 parts of dispersant, 0.3 parts of defoamer, 0.3 parts of wetting agent, 0.3 parts of leveling agent, 0.5 parts of thickener, AMP 1.2 parts of -95 neutralizer, 20 parts of deionized water, among them, the calcium-manganese naphthenate composite drier is calcium naphthenate, manganese naphthenate, and isobutanol in a mass ...

Embodiment 3

[0037] An environment-friendly anti-corrosion and quick-drying self-drying paint with bottom and surface in one. The raw materials are composed of 10 parts by mass of acrylic modified epoxy ester resin, 20 parts of styrene modified acrylic resin, calcium manganese naphthenate catalyst 1.5 parts of dry agent, 2 parts of organically modified zinc phosphate hydrate containing calcium strontium aluminum, 2 parts of iron oxide red, 1 part of mica powder, 5 parts of sunfast red powder, 10 parts of modified superfine precipitated barium sulfate, anti-flash 1 part of rust agent, 0.5 part of dodecyl alcohol ester, 1 part of dipropylene glycol methyl ether, 0.2 part of dispersant, 0.1 part of defoamer, 0.1 part of wetting agent, 0.1 part of leveling agent, 0.3 part of thickener, AMP 0.8 parts of -95 neutralizer, 15 parts of deionized water, among them, the calcium-manganese naphthenate composite drier is calcium naphthenate, manganese naphthenate, and isobutanol in a mass ratio of 1:1:1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com