Two-gradient phase-change thermal storage material and preparation method thereof

A phase change heat storage and gradient technology, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of high production cost and complex process of adipic acid heat storage materials, and avoid the phenomenon of phase separation, phase separation, etc. The effect of changing latent heat and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The raw material components and mass ratio of the two-gradient phase change heat storage material are: p-methoxyphenol 38%, pyrogallol 48%, nano-scale silicon dioxide 6%, nano-scale graphite powder 4%, fatty acid polyoxyethylene Ester nonionic surfactant 2%, hydroquinone 2%.

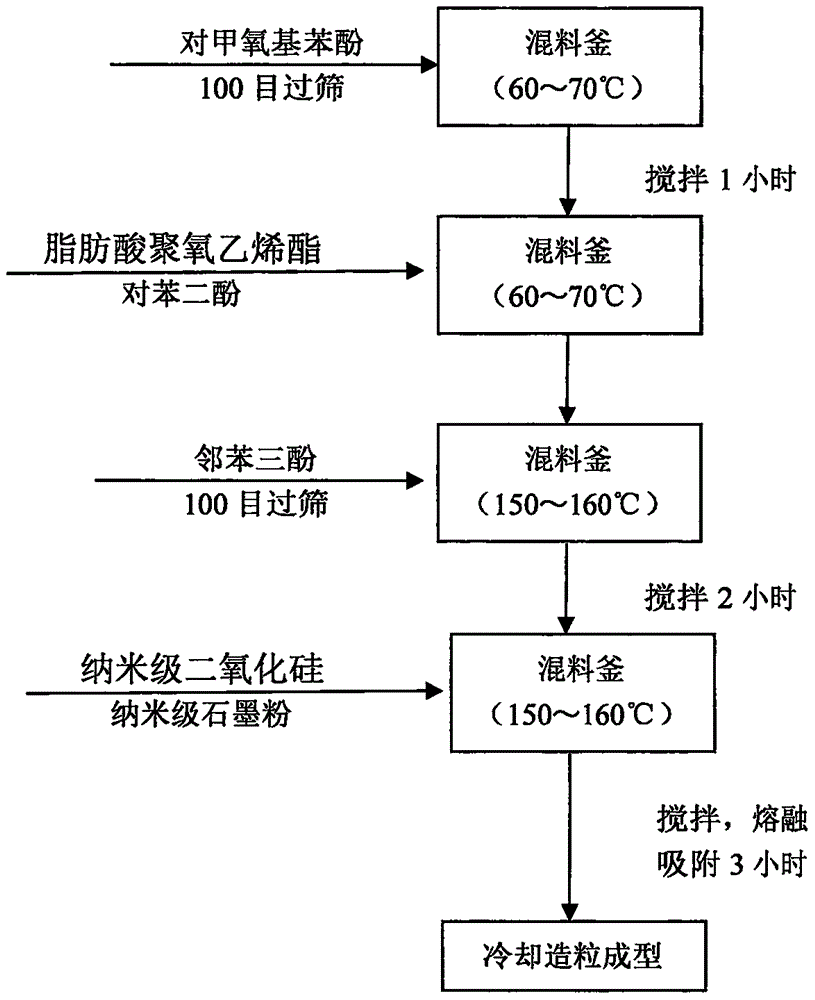

[0027] Press when preparing figure 1 As shown, first add 100-mesh sieved p-methoxyphenol into the mixing tank, heat to 60-70°C, and stir for 1 hour to completely melt p-methoxyphenol, then add fatty acid polyoxyethylene ester, p-methoxyphenol in sequence Hydroquinone. Continue stirring to raise the temperature to 150-160°C, add pyrogallol through a 100-mesh sieve into the mixing tank, and stir for 2 hours to completely melt the pyrogallol and mix it with p-methoxyphenol, and then add nano-scale Silica and nano-scale graphite powder are melted and adsorbed at a temperature of 150-160°C for 3 hours. The generated phase change material is sent to a granulator to obtain the medium and low temperatu...

Embodiment 2

[0030] The raw material components and mass ratio of the two-gradient phase change heat storage material are: p-methoxyphenol 40%, pyrogallol 46%, nano-scale silicon dioxide 5%, nano-scale graphite powder 5%, fatty acid polyoxyethylene Ester nonionic surfactant 2%, hydroquinone 2%.

[0031] Press when preparing figure 1 As shown, first add 100-mesh sieved p-methoxyphenol into the mixing tank, heat to 60-70°C, and stir for 1 hour to completely melt p-methoxyphenol, then add fatty acid polyoxyethylene ester, p-methoxyphenol in sequence Hydroquinone. Continue stirring to raise the temperature to 150-160°C, add pyrogallol through a 100-mesh sieve into the mixing tank, and stir for 2 hours to completely melt the pyrogallol and mix it with p-methoxyphenol, and then add nano-scale Silica and nano-scale graphite powder are melted and adsorbed at a temperature of 150-160°C for 3 hours. The generated phase change material is sent to a granulator to obtain the medium and low temperatu...

Embodiment 3

[0034]The raw material components and mass ratio of the two-gradient phase change heat storage material are: p-methoxyphenol 42%, pyrogallol 45%, nano-scale silicon dioxide 4%, nano-scale graphite powder 5%, fatty acid polyoxyethylene Ester nonionic surfactant 2%, hydroquinone 2%.

[0035] Press when preparing figure 1 As shown, first add 100-mesh sieved p-methoxyphenol into the mixing tank, heat to 60-70°C, and stir for 1 hour to completely melt p-methoxyphenol, then add fatty acid polyoxyethylene ester, p-methoxyphenol in sequence Hydroquinone. Continue stirring to raise the temperature to 150-160°C, add pyrogallol through a 100-mesh sieve into the mixing tank, and stir for 2 hours to completely melt the pyrogallol and mix it with p-methoxyphenol, and then add nano-scale Silica and nano-scale graphite powder are melted and adsorbed at a temperature of 150-160°C for 3 hours. The generated phase change material is sent to a granulator to obtain the medium and low temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com