A high temperature anaerobic fermentation system for kitchen waste

A technology for high-temperature anaerobic fermentation and kitchen waste, applied in bioreactor/fermenter combination, waste fuel, specific-purpose bioreactor/fermenter, etc., can solve the problem of slow hydrolysis and achieve work efficiency High, good separation effect, good desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

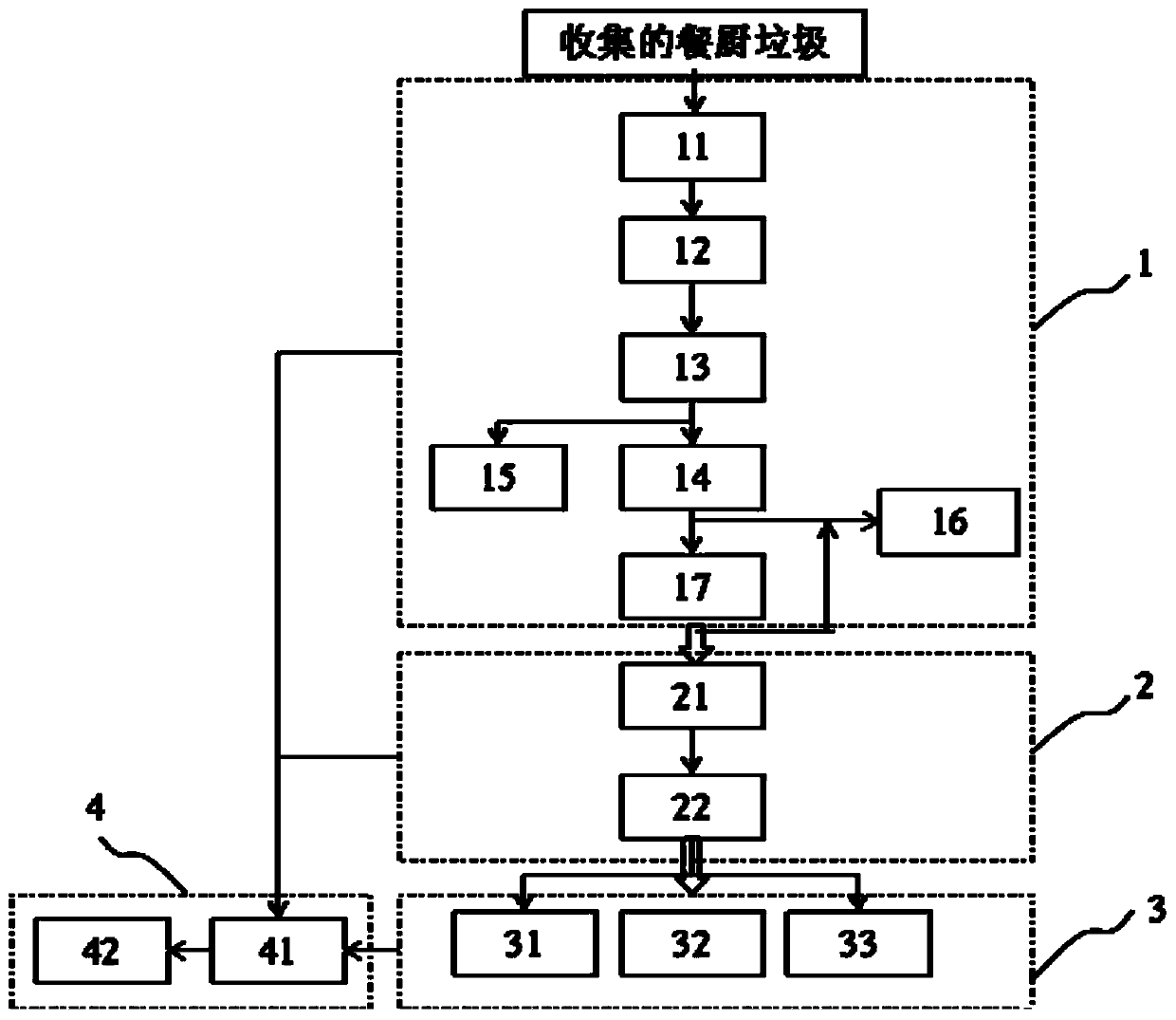

[0028] Such as figure 1 As shown, the high-temperature anaerobic fermentation system for kitchen waste provided by the present invention mainly includes a pretreatment section 1, an anaerobic fermentation section 2, a posttreatment section 3 and a deodorization section 4, and the pretreatment section 1 includes a metering system 11, a closed Type receiving hopper 12, oil-water separator 13, sorting and crushing device 14, grease processing device 15, bulk object processing device 16 and sand removal device 17, anaerobic fermentation section 2 includes hydrolysis acidification tank 21 and high temperature anaerobic fermentation tank 22 The post-treatment section 3 includes a biogas slurry treatment device 31, a biogas residue treatment device 32, and a biogas purification device 33. The deodorization section 4 includes a chemical desulfurization device 41 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com