Method for determining corn starch gelatinization degree

A technology of corn starch and measurement method, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, so as to achieve accurate and effective results, accurate measurement results, and low prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

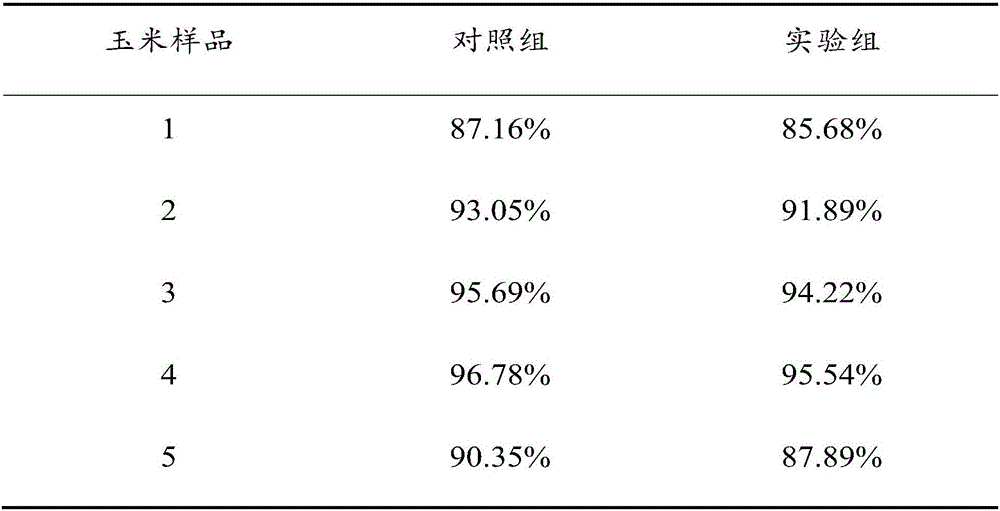

Embodiment 1

[0029] Two portions of corn of 0.5 g were weighed, respectively added to 150 mL Erlenmeyer flasks containing 45 mL of anhydrous sodium acetate-acetic acid buffer solution with a pH of 4.4, as the first sample and the second sample. Set up an empty sample containing only the above anhydrous sodium acetate-acetate buffer. Heat the first sample at 95°C for 45min; after cooling, add 2mL of compound amylase solution to the first sample, the second sample and the blank sample respectively. The enzyme activity of the compound amylase is 3300U / g, 1300U / g and 25U / g of glucoamylase, α-amylase and debranched amylase. Heat the first sample, the second sample and the empty sample added with the compound enzyme amylase solution at 38°C for 43 minutes, then add 2mL of sulfuric acid solution and sodium tungstate solution in sequence and shake well; set the volume to 100mL , filtered, and the filtrates of the three were collected respectively to obtain a fully gelatinized sample, a sample to...

Embodiment 2

[0032] Weigh two portions of 0.9 g corn crushed to 35 mesh, and add them to 150 mL Erlenmeyer flasks containing 55 mL of anhydrous sodium acetate-acetic acid buffer solution with a pH of 4.7 as the first sample and the second sample. Set up an empty sample containing only the above anhydrous sodium acetate-acetate buffer. Heat the first sample at 100°C for 35min; after cooling, add 2mL of compound amylase solution to the first sample, the second sample and the blank sample respectively. The enzyme activity of the compound amylase is 3700U / g, 1700U / g and 35U / g of glucoamylase, α-amylase and debranched amylase. Heat the first sample, the second sample and the blank sample added with the compound enzyme amylase solution at 43°C for 38min, then add 2mL of sulfuric acid solution and sodium tungstate solution in sequence and shake well; set the volume to 100mL , filtered, and the filtrates of the three were collected respectively to obtain a fully gelatinized sample, a sample to b...

Embodiment 3

[0035] Weigh two portions of 0.7 g corn crushed to 45 mesh, and add them to 150 mL Erlenmeyer flasks containing 50 mL of anhydrous sodium acetate-acetic acid buffer solution with a pH of 4.5, respectively, as the first sample and the second sample. Set up an empty sample containing only the above anhydrous sodium acetate-acetate buffer. Heat the first sample at 98°C for 40min; after cooling, add 2mL of compound amylase solution to the first sample, the second sample and the blank sample respectively. The enzyme activity of the compound amylase is 3500U / g, 1500U / g and 30U / g of glucoamylase, α-amylase and debranched amylase. Heat the first sample, the second sample and the empty sample added with the compound enzyme amylase solution at 40°C for 40 minutes, then add 2 mL of sulfuric acid solution and sodium tungstate solution in sequence and shake well; set the volume to 100 mL , filtered, and the filtrates of the three were collected respectively to obtain a fully gelatinized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com