Fireproof cable for nuclear power station and preparation method of fireproof cable

A technology for fireproof cables and nuclear power plants, which is applied in the directions of insulated cables, cables, circuits, etc., can solve the problems that ordinary cables are difficult to achieve, and achieve good application prospects, play a flame retardant effect, and simple processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

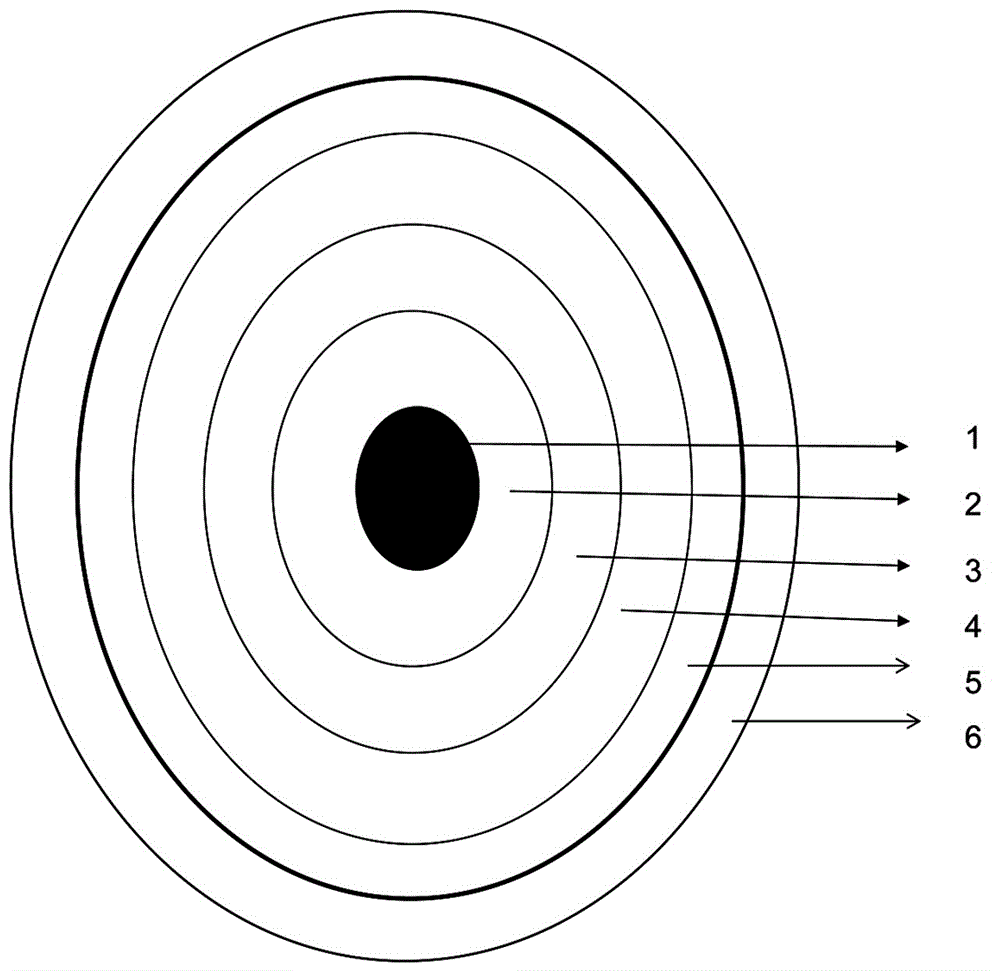

Image

Examples

Embodiment 1

[0016] The copper rod is drawn on a wire drawing machine, then annealed and then coiled for use. 100 parts by mass of dimethyl silicone rubber, 25 parts of silicon dioxide, 3 parts of diphenylsilanediol, 2 parts of dicumyl peroxide, and 1 part of auxiliary agent BHT were kneaded in a vacuum kneader for 5 Minutes, followed by mixing with an internal mixer for 10 minutes to obtain a silicone rubber masterbatch, and then extruding the silicone rubber masterbatch through a special extruder for rubber cables at 60°C to coat the copper core wire to form a ceramic silicone rubber Insulation fire layer. Then, silicon dioxide is coated on the ceramicized silicone rubber insulating fireproof layer by coating equipment to form a radiation-resistant layer. 100 parts of polyethylene, 18 parts of ammonium polyphosphate, 2 parts of benzoyl peroxide and 3 parts of additive BHT were mixed through a mixer for 5 minutes to obtain a halogen-free flame-retardant polyethylene cable compound. The ...

Embodiment 1

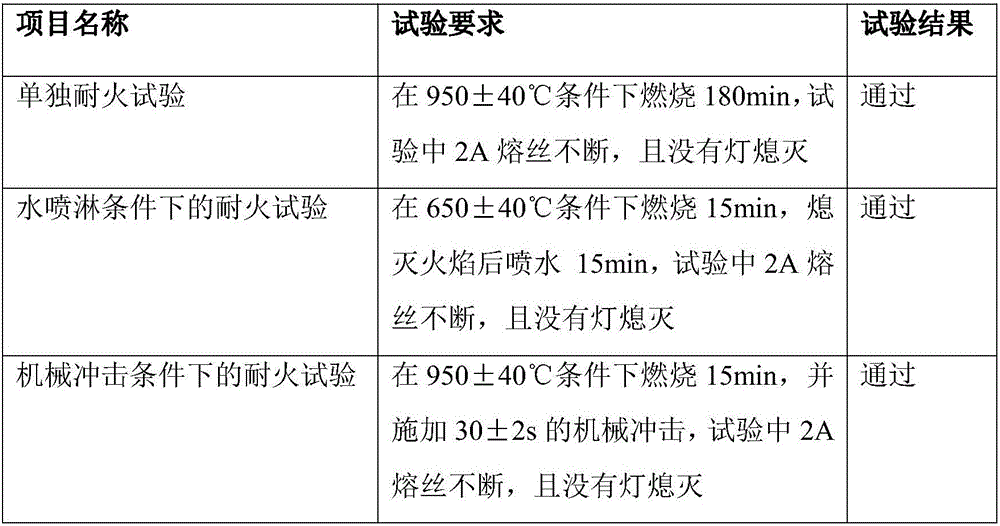

[0017] Table 1 Embodiment 1 The fireproof performance (fire resistance characteristic test) of a kind of nuclear power plant fireproof cable

[0018]

Embodiment 2

[0020] The copper rod is drawn on a wire drawing machine, then annealed and then coiled for use. Knead 100 parts by mass of methyl vinyl silicone rubber, 30 parts of silicon dioxide, 2 parts of diphenylsilanediol, 2 parts of dicumyl peroxide, and 5 parts of auxiliary agent BP-2 in a vacuum Machine kneading for 8 minutes, followed by internal mixer kneading for 20 minutes to obtain a silicone rubber masterbatch, and then the silicone rubber masterbatch is extruded and coated on the copper core wire at 80°C through a special extruder for rubber cables to form a ceramic Silicone rubber insulating fireproof layer. Then, silicon dioxide is coated on the ceramicized silicone rubber insulating fireproof layer by coating equipment to form a radiation-resistant layer. Mix 100 parts of polyethylene, 18 parts of ammonium polyphosphate, 1 part of benzoyl peroxide and 2 parts of additive BP-2 through a mixer for 5 minutes to obtain a halogen-free flame-retardant polyethylene cable compoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com