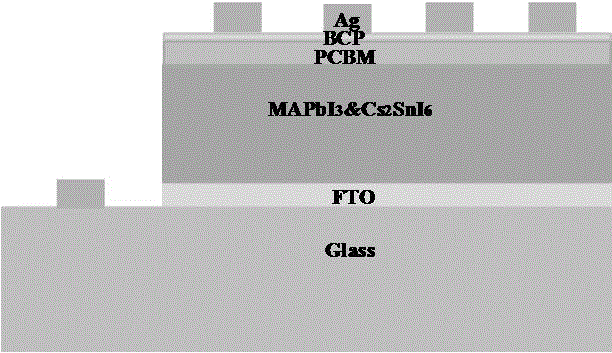

Cs2SnI6-CH3NH3PbI3 bulk heterojunction-based solar cell and preparation method thereof

A technology of solar cells and bulk heterojunctions, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems affecting the photoelectric conversion efficiency of cells, affecting current, etc., to facilitate the promotion of industrialization, improve crystallinity and grain size , High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Cs 2 SnI 6 Powder preparation: SnI 4 Dissolve the powder in warm ethanol solution, dissolve CsI powder in DMF solution, mix the above solutions and let stand to precipitate Cs 2 SnI 6 Crystals, filtered and dried;

[0025] (2) Cut FTO transparent conductive glass into 1.6×1.7cm substrates, then ultrasonically clean with lye for 30-60 min, then ultrasonically clean with alcohol for 30-60 min, and finally clean with distilled water for 10-30 min, then Put it in the drying box to dry for later use;

[0026] (3) PbI 2 、CH 3 NH 3 I powder was dissolved in dimethylformamide (DMF) at a molar ratio of 1:1, and stirred at 70°C for 5 hours to obtain a precursor solution;

[0027] (4) Add 2.5 mg Cs to the precursor solution in (3) above 2 SnI 6 powder, stirred at room temperature for 2h to obtain a mixed solution;

[0028] (5) Spin-coat the solution obtained in (4) above on the FTO transparent conductive glass in (2) at a speed of 4000r / min, and anneal at 100°C for ...

Embodiment 2

[0033] (1) Cs 2 SnI 6 Powder preparation: SnI 4 Dissolve the powder in warm ethanol solution, dissolve CsI powder in DMF solution, mix the above solutions and let stand to precipitate Cs 2 SnI 6 Crystals, filtered and dried;

[0034] (2) Cut FTO transparent conductive glass into 1.6×1.7cm substrates, then ultrasonically clean with lye for 30-60 min, then ultrasonically clean with alcohol for 30-60 min, and finally clean with distilled water for 10-30 min, then Put it in the drying box to dry for later use;

[0035] (3) PbI 2 、CH 3 NH 3 I powder was dissolved in dimethylformamide (DMF) at a molar ratio of 1:1, and stirred at 70°C for 5 hours to obtain a precursor solution;

[0036] (4) Add 6.6 mg of Cs to the precursor solution in (3) above 2 SnI 6 powder, stirred at room temperature for 2h to obtain a mixed solution;

[0037](5) Spin-coat the solution obtained in (4) above on the FTO transparent conductive glass in (2) at a speed of 4000r / min, and anneal at 100°C fo...

Embodiment 3

[0043] (1) Cs 2 SnI 6 Powder preparation: SnI 4 Dissolve the powder in warm ethanol solution, dissolve CsI powder in DMF solution, mix the above solutions and let stand to precipitate Cs 2 SnI 6 Crystals, filtered and dried;

[0044] (2) Cut FTO transparent conductive glass into 1.6×1.7cm substrates, then ultrasonically clean with lye for 30-60 min, then ultrasonically clean with alcohol for 30-60 min, and finally clean with distilled water for 10-30 min, then Put it in the drying box to dry for later use;

[0045] (3) PbI 2 、CH 3 NH 3 I powder was dissolved in dimethylformamide (DMF) at a molar ratio of 1:1, and stirred at 70°C for 5 hours to obtain a precursor solution;

[0046] (4) Add 15 mg of Cs to the precursor solution in (3) above 2 SnI 6 powder, stirred at room temperature for 2h to obtain a mixed solution;

[0047] (5) Spin-coat the solution obtained in (4) above on the FTO transparent conductive glass in (2) at a speed of 4000r / min, and anneal at 100°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com