Preparation method and fresh keeping technology of sweet cherry fresh keeping agent

The technology of a preservative and sweet cherries is applied in the preservation of fruits and vegetables, food preservation, preservation of food ingredients as anti-microbials, etc. , strong corrosion resistance, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

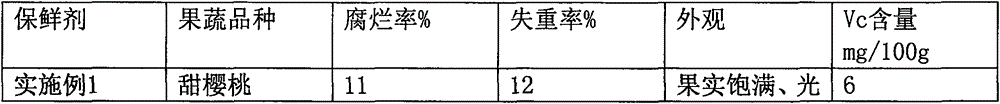

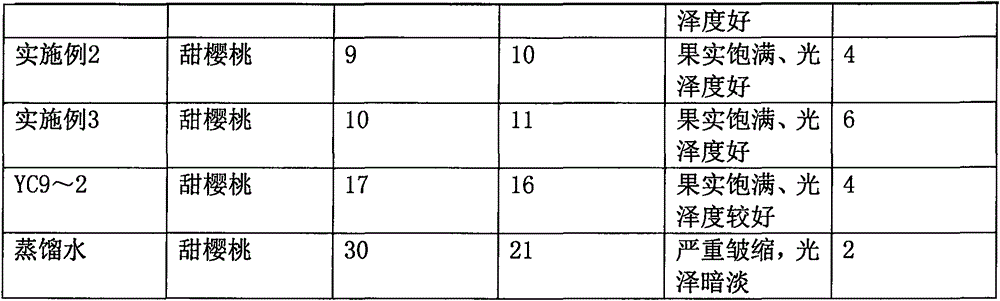

Examples

Embodiment 1

[0027] S1. After the collected Litsea Cubeba is ultrafinely pulverized, add 6 to 10 times the volume of 90% ethanol solution, and treat for 1 to 3 minutes. After solid-liquid separation, recover the ethanol solution and concentrate, so that the extract is in the form of a thick paste; Then, after dispersing with appropriate water, extract three times with dichloromethane and ethyl acetate successively, and continue to extract the obtained filter residue part by cold immersion in water three times, each time for 20 hours, and combine all the extracts to obtain Litsea cubeba extract ;

[0028] S2. After processing the collected mustard seeds with a flash extractor, the obtained extract is first heated with strong fire, then heated with slow fire for 1 to 1.5 hours after boiling, and filtered with a hollow fiber ultrafiltration membrane; add 10 to 20 times of water to decoct the dregs Boil twice, filter with hollow fiber ultrafiltration membrane, combine three times of filtrate, ...

Embodiment 2

[0033]S1. After the collected Litsea Cubeba is ultrafinely pulverized, add 6 to 10 times the volume of 90% ethanol solution, and treat for 1 to 3 minutes. After solid-liquid separation, recover the ethanol solution and concentrate, so that the extract is in the form of a thick paste; Then, after dispersing with appropriate water, extract three times with dichloromethane and ethyl acetate successively, and continue to extract the obtained filter residue part by cold immersion in water three times, each time for 20 hours, and combine all the extracts to obtain Litsea cubeba extract ;

[0034] S2. After processing the collected mustard seeds with a flash extractor, the obtained extract is first heated with strong fire, then heated with slow fire for 1 to 1.5 hours after boiling, and filtered with a hollow fiber ultrafiltration membrane; add 10 to 20 times of water to decoct the dregs Boil twice, filter with hollow fiber ultrafiltration membrane, combine three times of filtrate, c...

Embodiment 3

[0039] S1. After the collected Litsea Cubeba is ultrafinely pulverized, add 6 to 10 times the volume of 90% ethanol solution, and treat for 1 to 3 minutes. After solid-liquid separation, recover the ethanol solution and concentrate, so that the extract is in the form of a thick paste; Then, after dispersing with appropriate water, extract three times with dichloromethane and ethyl acetate successively, and continue to extract the obtained filter residue part by cold immersion in water three times, each time for 20 hours, and combine all the extracts to obtain Litsea cubeba extract ;

[0040] S2. After processing the collected mustard seeds with a flash extractor, the obtained extract is first heated with strong fire, then heated with slow fire for 1 to 1.5 hours after boiling, and filtered with a hollow fiber ultrafiltration membrane; add 10 to 20 times of water to decoct the dregs Boil twice, filter with hollow fiber ultrafiltration membrane, combine three times of filtrate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com