Mercury removal adsorbent for flue gas as well as preparation method and application thereof

An adsorbent and mercury removal technology, which is applied in the field of air purification, can solve the problems of low mercury removal efficiency, achieve the effects of simple preparation method, avoid activity, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a mercury removal adsorbent for flue gas and its preparation method and application; the preparation method comprises the following steps:

[0029] S1. Select a cerium-zirconium-based solid solution with a particle size of 20 μm to 200 μm (ie Ce (1-x) Zr x o 2 ) powder is immersed in copper chloride solution for more than 3min, so that the Ce (1-x) Zr x o 2 Copper oxide is loaded on the surface of the powder; the concentration of the copper chloride solution is 10g / L to 500g / L, and the concentration of the copper chloride solution and the time of immersion will affect the Ce (1-x) Zr x o 2 Loading capacity of powder; the time of immersion is preferably 5min~10min, at this time, Ce (1-x) Zr x o 2 If the powder is immersed in an equal volume of copper chloride solution, it can absorb about 95% of copper chloride; if the soaking time is too long or the concentration is too high, the mass fraction of copper oxide will be high, otherwise it wi...

Embodiment 1

[0035] (1) Prepare cerium-zirconium solid solution powder by sol-gel method (for the preparation method, refer to the literature "Zhou etal.Manganese doped CeO 2 -ZrO 2 catalyst for elemental mercury oxidation at low temperature."(Fuel Processing Technology 152,285-293), its molecular formula is Ce 0.67 Zr 0.33 o 2 , the particle size range of powder particles ranges from 50 μm to 100 μm;

[0036] (2) immerse 5.64g of cerium-zirconium solid solution in an equal volume of 76g / L copper chloride aqueous solution for 5min;

[0037] (3) In an air atmosphere, the cerium-zirconium solid solution obtained in the step (2) was left to dry at 25°C for 24 hours, and then dried in an oven at 65°C for 12 hours to obtain powdered 6g loaded chloride The adsorbent of copper, the mass fraction of copper chloride in the adsorbent is 6%.

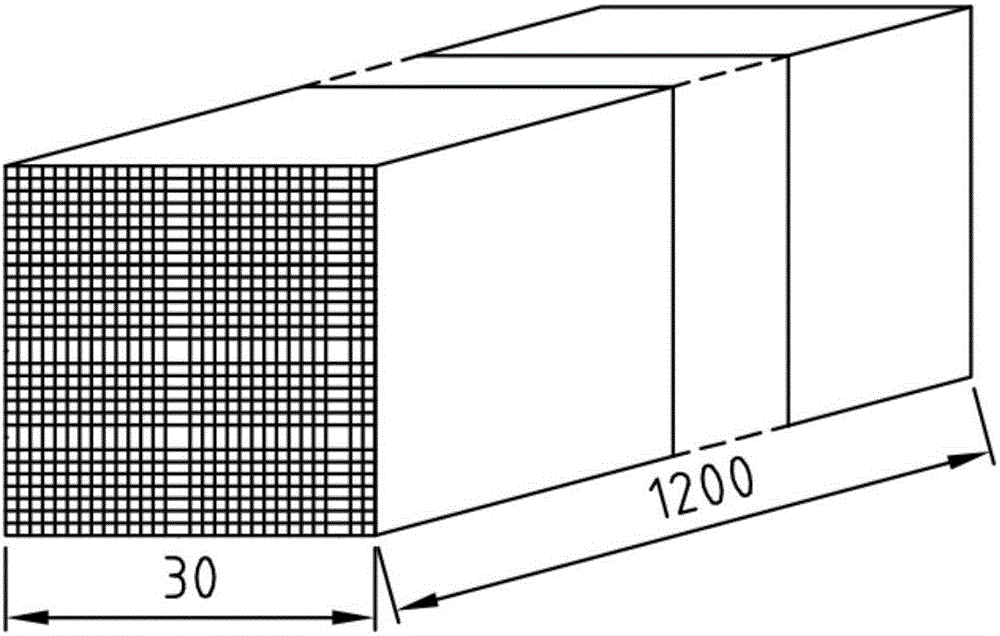

[0038] (4) The powdered adsorbent is extruded into a honeycomb adsorbent through a die. The length of the honeycomb adsorbent is 1200mm, the cross section...

Embodiment 2

[0040] Repeat Example 1 with the same steps as described, the difference is that in the step (4), the honeycomb adsorbent is installed after the economizer and dust collector.

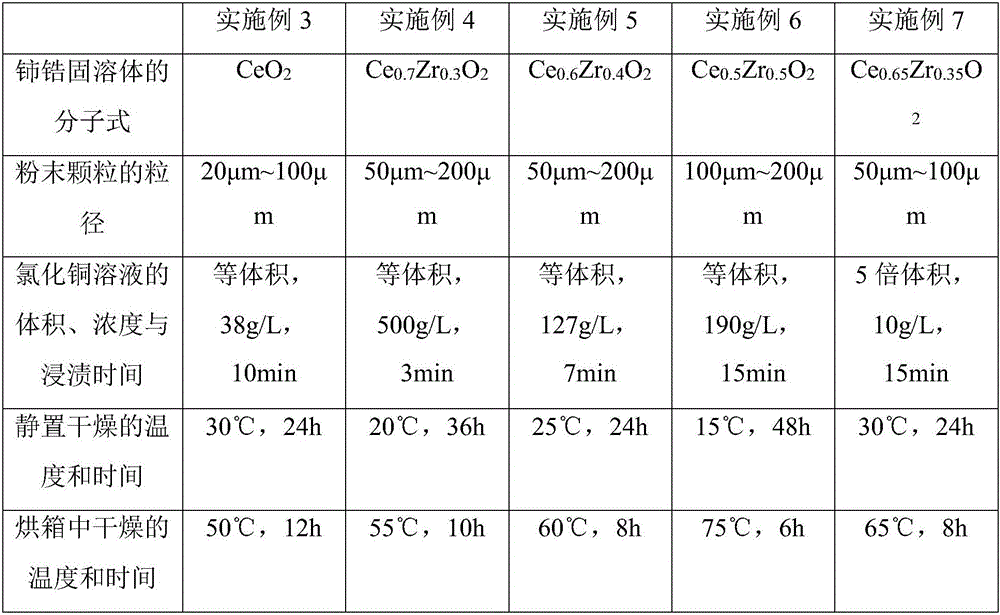

[0041] The adsorbents of Examples 3-6 were prepared in the same steps as in Example 1, the specific preparation parameters are shown in Table 1, and the parameters and methods not listed in the table were the same as in Example 1.

[0042] Table 1

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com