Graphene modified sodium alginate-polyacrylonitrile heterogeneous enhanced type hollow fiber membrane

A graphene modification and sodium alginate technology, applied in the field of hollow fiber membranes, can solve the problems of indeterminate pore size of braided tubes, poor filtration performance, and insufficient uniformity, and achieve improved mechanical properties, excellent hydrophilicity, and improved mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

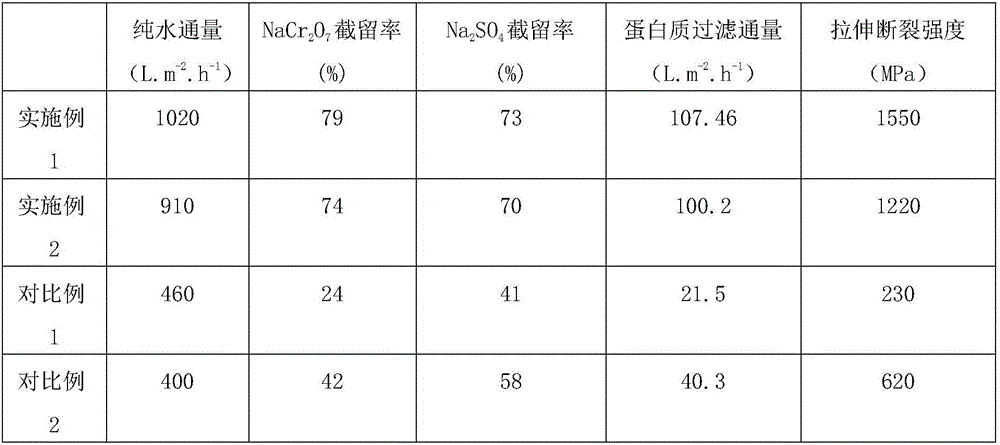

Examples

Embodiment 1

[0019] Preparation of reinforcement base membrane: Disperse a certain proportion of PVDF in the solvent DMAC, stir at a constant temperature at 70°C until the polymer is completely dissolved, stand for defoaming, and prepare polyvinylidene fluoride hollow fiber membrane by melt spinning method, and The membrane is used as the base membrane of the graphene-modified sodium alginate-polyacrylonitrile heterogeneously reinforced hollow fiber membrane.

[0020] Preparation of the casting solution: prepare raw materials of the following quality: 30 g of polyacrylonitrile, 10 g of graphene, 20 g of sodium alginate, 40 g of dimethylformamide, and 50 g of ethylene glycol.

[0021] Dissolve polyacrylonitrile with a molecular weight of 32,000 in dimethylformamide solution to prepare spinning stock solution 1, mix graphene with sodium alginate, dissolve it in ethylene glycol solution, and let it stand at room temperature for 2 hours to prepare Spinning stock solution 2, slowly inject spinn...

Embodiment 2

[0024] Preparation of reinforcement base membrane: Disperse a certain proportion of PVDF in the solvent DMAC, stir at a constant temperature at 70°C until the polymer is completely dissolved, stand for defoaming, and prepare polyvinylidene fluoride hollow fiber membrane by melt spinning method, and The membrane is used as the base membrane of the graphene-modified sodium alginate-polyacrylonitrile heterogeneously reinforced hollow fiber membrane.

[0025] Preparation of the casting solution: prepare the following raw materials: 20 g of polyacrylonitrile, 5 g of graphene, 15 g of sodium alginate, 35 g of dimethyl sulfoxide, and 45 g of isopropanol.

[0026] Dissolve polyacrylonitrile with a molecular weight of 42,000 in dimethyl sulfoxide solution to prepare spinning stock solution 1, mix graphene and sodium alginate, dissolve in isopropanol solution, and let it stand at room temperature for 1.5 hours to prepare Spinning stock solution 2, slowly inject spinning stock solution 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com